Imagine where your electronic devices work perfectly, never failing when you need them most. Sounds appealing, right?

Precision CNC parts are vital in consumer devices because they offer unparalleled accuracy, boosting durability and reliability in everyday gadgets.

Ever wondered why your high-tech devices never disappoint? Precision engineering might be the reason.

How Does CNC Manufacturing Support Sustainability in Electronics?

Consider the environmental impact of disposable electronics filling landfills. It’s a growing problem we all face today.

CNC manufacturing in electronics helps reduce waste and energy consumption, promoting sustainability by ensuring precise and efficient use of materials.

Transitioning to sustainable practices in electronics is crucial. CNC manufacturing aids this by optimizing material usage, reducing excess, and minimizing waste. The precision offered by CNC machines ensures that each component is manufactured to exact specifications, leading to less scrap and fewer reworks. Furthermore, CNC technology allows for the use of eco-friendly materials more effectively, as it can handle complex designs that traditional methods might struggle with. As more manufacturers prioritize sustainability, CNC machining plays a pivotal role by aligning production processes with environmental goals. This not only helps the planet but also enhances brand reputation among eco-conscious consumers.

How Can Precision CNC Parts Unlock Greater Design Freedom for Your Devices?

Think about the endless possibilities of design innovation. Restrictive manufacturing processes shouldn't hold you back!

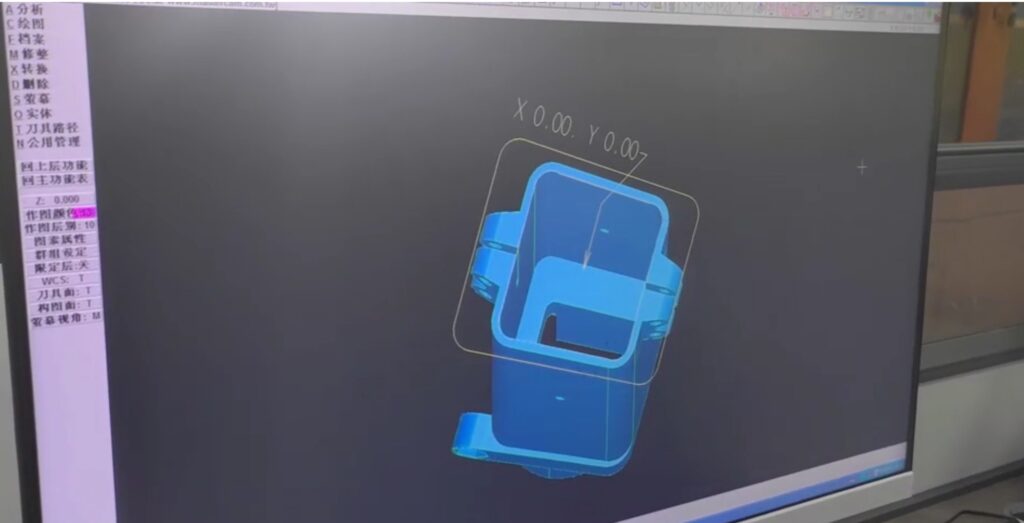

Precision CNC parts allow for complex and intricate designs, granting designers more freedom to innovate and enhance device aesthetics and functionality.

Designers often face limitations due to manufacturing constraints. However, CNC machining opens doors to creativity by offering unrivaled accuracy and flexibility. With its capability to produce intricate geometries, CNC machining allows for the creation of unique shapes and designs that were once impossible. This not only enhances the aesthetic appeal of consumer devices but also enables the integration of advanced functionalities. High precision ensures that parts fit perfectly, reducing the risk of assembly errors and improving overall device performance. By removing traditional barriers, CNC technology empowers designers to push the boundaries of innovation, leading to more advanced and attractive products.

Why Does CNC Machining Lead to Superior Product Quality and Consistency?

Quality matters, especially when it comes to devices we rely on daily. Who wouldn’t want unyielding reliability in their gadgets?

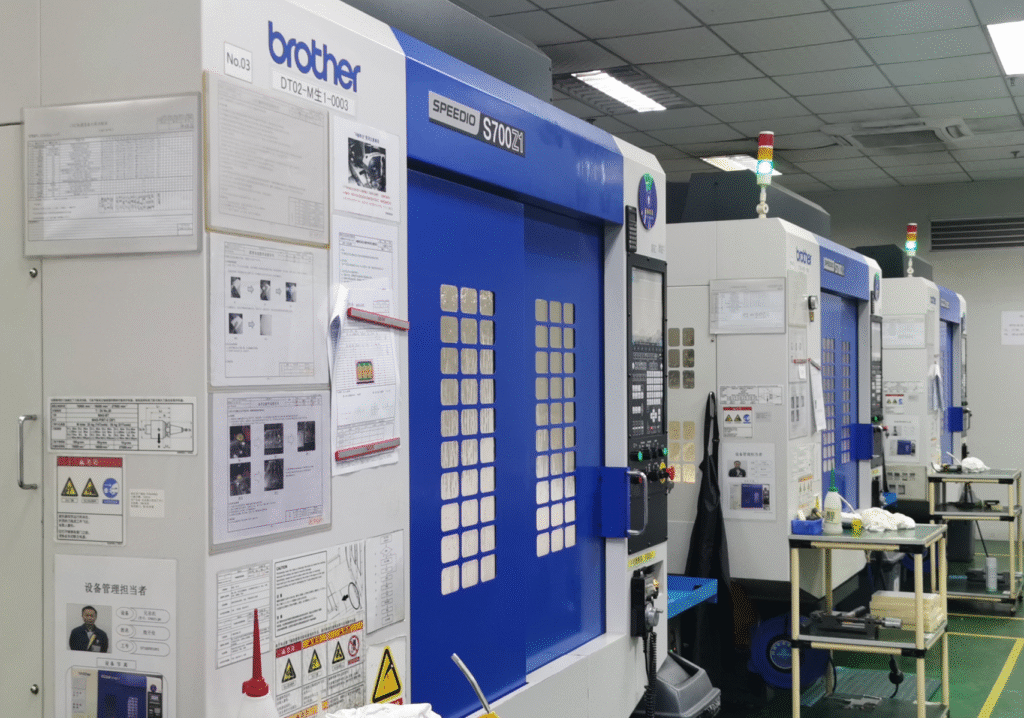

CNC machining boosts product quality and consistency because it allows for precisely controlled, repeatable manufacturing processes, eliminating human error.

Achieving high-quality standards consistently is a challenge for many manufacturers. CNC machining addresses this by offering a level of precision that manual methods simply cannot match. It enables the production of each part to exact specifications, ensuring uniform quality and reducing the margin for error. This consistency translates into reliable products that perform as expected, time after time. By automating the manufacturing process, CNC machines minimize human intervention, thus mitigating variability and potential mistakes. This leads to fewer defects, lower failure rates, and ultimately, a more satisfying experience for the end user. Such reliability enhances consumer trust and brand loyalty.

Is Precision CNC Machining a Cost-Effective Choice for Mass Production?

Cost efficiency in manufacturing means businesses can focus resources on innovation. Isn’t that a win-win?

Precision CNC machining is cost-effective for mass production because it reduces labor costs, material waste, and time, ensuring streamlined operations and significant savings.

Balancing quality with cost is a perennial challenge in manufacturing. Precision CNC machining offers a solution by optimizing production processes and reducing costs. It significantly cuts down on wasted materials by utilizing precise measurements and minimizing errors. Additionally, CNC machines operate continuously with minimal supervision, reducing labor costs. This efficiency leads to faster turnarounds and higher output rates, essential for mass production. Although initial investment in CNC technology might seem high, the long-term savings in reduced waste, labor, and enhanced productivity quickly offset these costs. Thus, CNC machining emerges as a cost-effective choice for businesses aiming to scale production without compromising on quality.

Conclusion

Precision CNC parts enhance sustainability, innovation, quality, and cost-efficiency in consumer devices, driving industry advancements.