Choosing the right CNC machining supplier can be overwhelming given the intricacies involved.

To ensure a successful partnership, it's essential to ask key questions about their capabilities, quality control, and lead times.

Finding the right balance between cost, quality, and delivery time can seem challenging.

What is the Supplier's Experience in Your Industry?

Understanding a supplier's industry experience can prevent costly miscommunications and delays.

Ask if they have worked on similar projects before. Industry experience ensures they understand specific requirements and compliance standards.

A supplier well-versed in your industry will know the typical challenges and best practices. They will have a track record and references that reflect their understanding. They can foresee potential issues and propose solutions early. Their experience can help ensure projects meet deadlines while maintaining quality standards.

How Does the Supplier Ensure Quality?

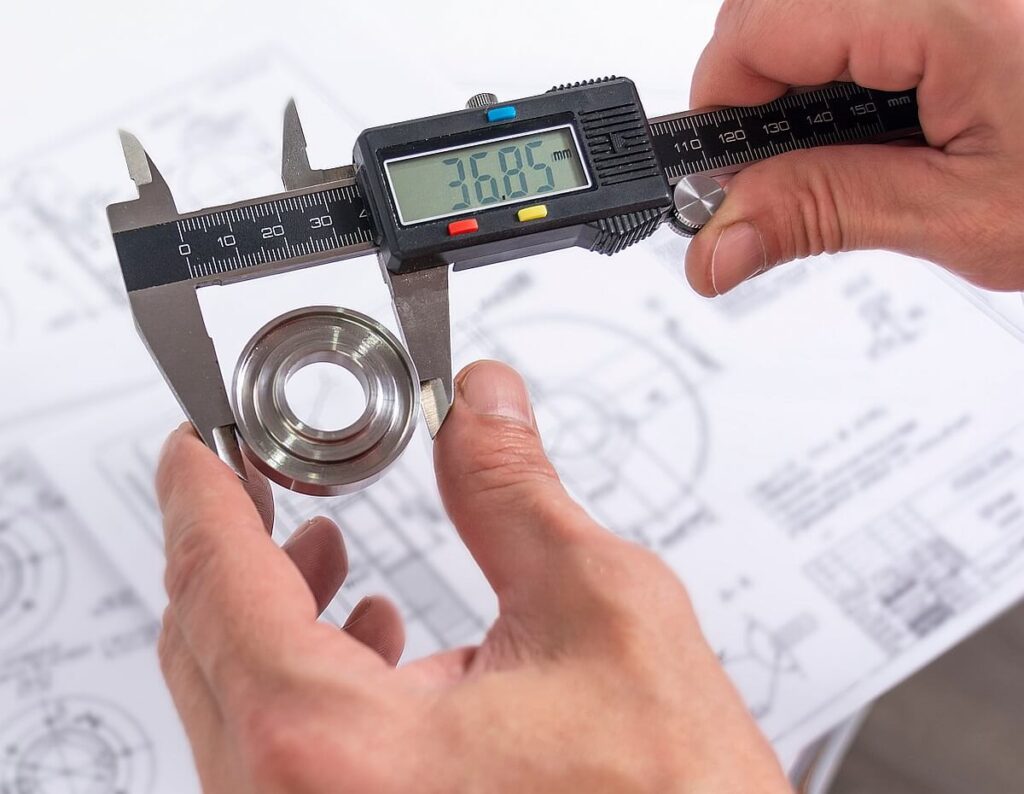

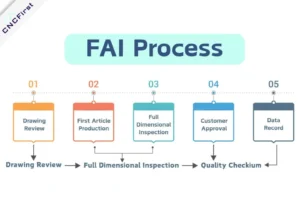

The absence of strong quality controls can lead to defective parts and wasted resources.

Quality assurance methods may include certifications, inspections, and testing. Confirm they follow ISO standards or others relevant to your industry.

A reliable supplier will have a detailed quality assurance plan. This might include first article inspections, in-process checks, and final inspections. They should use precise measurement tools and have a dedicated quality team. Understanding their defect management and continuous improvement measures is crucial too. It ensures they learn from past mistakes and enhance their processes.

What Are the Supplier's Lead Times and Capacity?

Surprises with lead times can disrupt your entire production schedule.

Ask about their current workload and lead times for typical orders. Know their capacity to scale up if necessary.

A supplier should share their production timeline transparently. Sunjoy's lead time is 2-4weeks. For some urgent items, leadtime can be one week. This includes setup time, machining, and shipping durations. Discuss their ability to handle rush orders or scale output for larger projects. Suppliers with robust planning tools and flexible manufacturing systems can better accommodate changes in demand without sacrificing quality or speed.

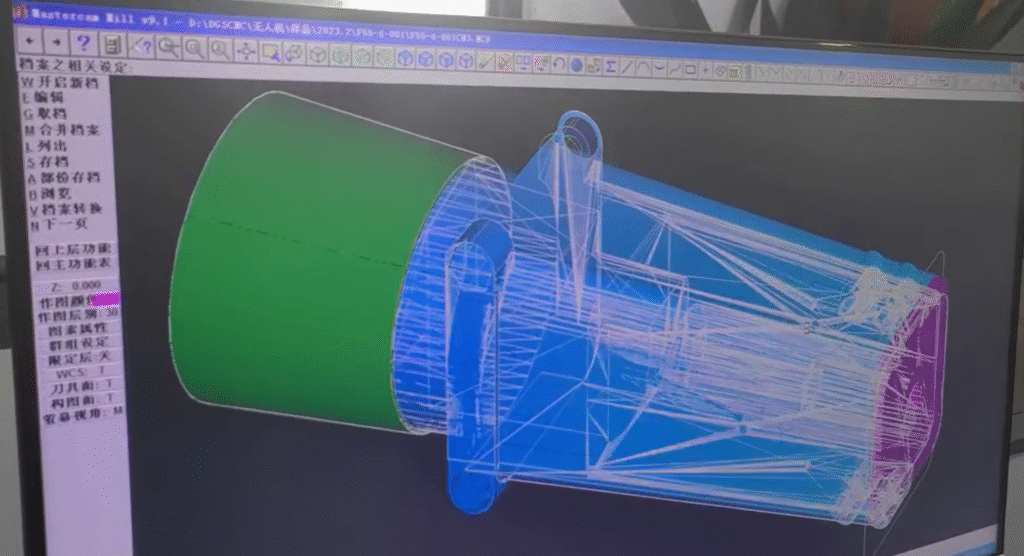

What Materials and Technologies Do They Work With?

Using the wrong materials or outdated technologies can compromise your product's durability and competitiveness.

Ensure they have expertise in the materials you require, and access to the latest CNC technologies.

Check if the supplier uses modern machinery. Advanced technologies often boast better tolerances and surface finishes. They should be able to machine a wide range of materials like metals, plastics, etc. This flexibility can be crucial for future product innovation. Suppliers that invest in cutting-edge machines show commitment to continuous improvement and competitiveness, which can be beneficial for both parties.

How Do They Handle Communication and Support?

Poor communication can lead to misunderstandings and costly errors. In Sunjoy, all emails can be replied within one day. Any changes need to get our customers' approvement via email. If necessary, we can call our customers at their business time.

Understand their customer service structure. Identify your point of contact and their availability for discussion or troubleshooting.

Effective communication is the backbone of any supplier relationship. Determine how updates are communicated. The frequency and clarity of these interactions matter. Suppliers should provide regular status reports and be responsive to queries. Escalation paths should be clear should issues arise. Consistent support ensures a smoother, more efficient partnership.

Conclusion

Choosing the right CNC supplier involves assessing their capabilities, experience, and support to avoid costly mistakes and ensure quality production.