Surface finishing can make or break your product’s quality. It's not just aesthetic; it impacts durability and functionality too.

Surface finishing in manufacturing enhances both appearance and performance by modifying the exterior of a part. This process can improve resistance to wear, corrosion, and impact, ensuring the product meets industry standards for quality.

Understanding the significance of surface finishes will help any manufacturer enhance product quality and meet customer expectations.

Why is surface finishing an important manufacturing process?

Surface finishing affects more than just looks—it's a key aspect in product longevity and function.

Surface finishing is crucial because it protects materials from environmental factors, reduces friction between moving parts, and can even enhance conductivity in some cases. This ensures the product functions effectively in its intended application.

It's clear that the right surface finish can drastically reduce maintenance costs and product failures. For instance, applying a corrosion-resistant coating can prevent rust in metal parts exposed to moisture. In addition, fine finishes reduce friction in components like gears, enhancing efficiency. Understanding these elements can transform the manufacturing approach and lead to higher customer satisfaction and lower returns.

What is the finishing process in manufacturing?

Finishing isn't just a final touch; it enhances function and forms the backbone of many manufacturing processes.

The finishing process involves various techniques to enhance a part's surface. This may include grinding, polishing, buffing, or coating, each chosen based on the desired properties and application of the part.

Each finishing method serves unique purposes.

Grinding levels surfaces for precision and accuracy.

Polishing can create reflective surfaces that improve part aesthetics.

Buffing smooths out minor imperfections, and coatings add additional protective layers.

Choosing the right process involves assessing material type, part application, and required durability, forming a critical component of the manufacturing workflow.

What is the standard surface finish for CNC?

The standard surface finish goes beyond visual appeal to integrate functionality and reliability into the design.

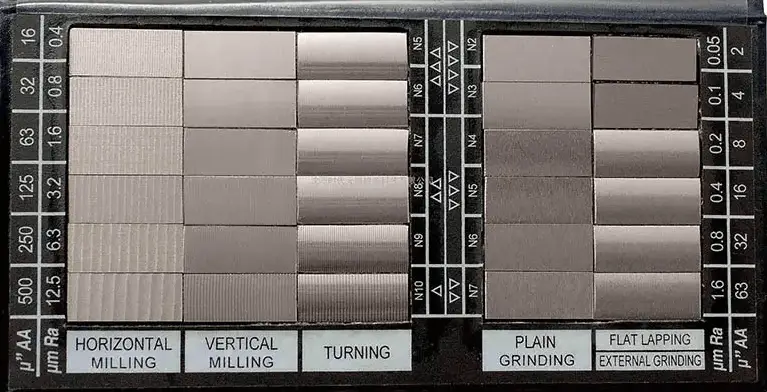

For CNC machining, the standard surface finish is often measured in Ra (roughness average) micrometers. Typical values range from 0.8 to 3.2 micrometers, depending on the part's functional requirements and application.

Besides just numbers, selecting or achieving the right surface finish involves understanding the relationship between the finish and the material's properties. Low Ra values typically indicate smoother surfaces, ideal for decorative or aesthetic functions. Higher values may be sufficient for components not visible in the final product. These considerations ensure that surface finishes align with the part's purpose and industry standards.

What are the methods of surface finish manufacturing?

Navigating the variety of finishing methods can be complex, but each method offers unique advantages.

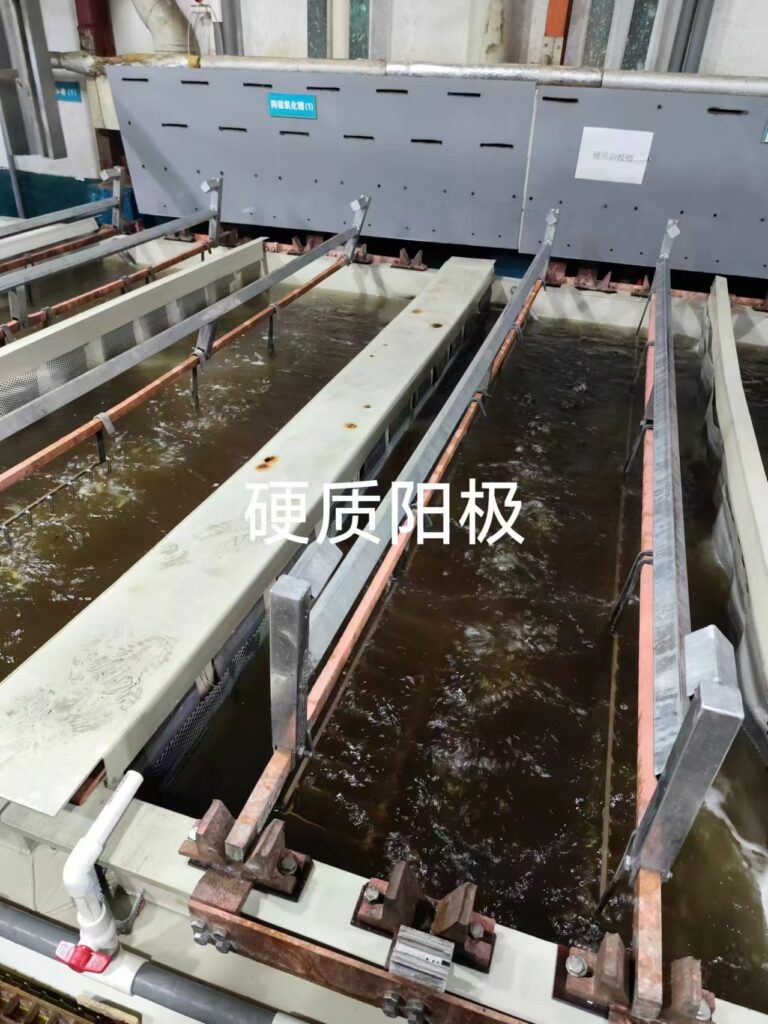

Methods include mechanical processes like sanding and tumbling, chemical processes like anodizing and plating, and thermal processes like heat treating. Each method is selected based on part material and desired surface characteristics.

Mechanical methods like sanding are great for achieving consistent textures on flat surfaces. Chemical methods like anodizing can provide both protective and decorative properties. Thermal methods like heat treating can enhance surface hardness. Each method's effectiveness varies based on material type and intended application, making an informed choice crucial to manufacturing success.

Conclusion

Surface finishing is more than a final touch; it defines quality, durability, and functionality in manufacturing.