20 Years of Excellence in Precision Manufacturing

Customized solutions to meet challenges - we provide solutions, not questions!

About Sunjoy CNC

Founded in 2005, Sunjoy specializes in high-precision CNC machining with 20 years of industry experience, consistently achieving tolerances of +/-0.005mm across aluminum, stainless steel, titanium, and copper alloys.

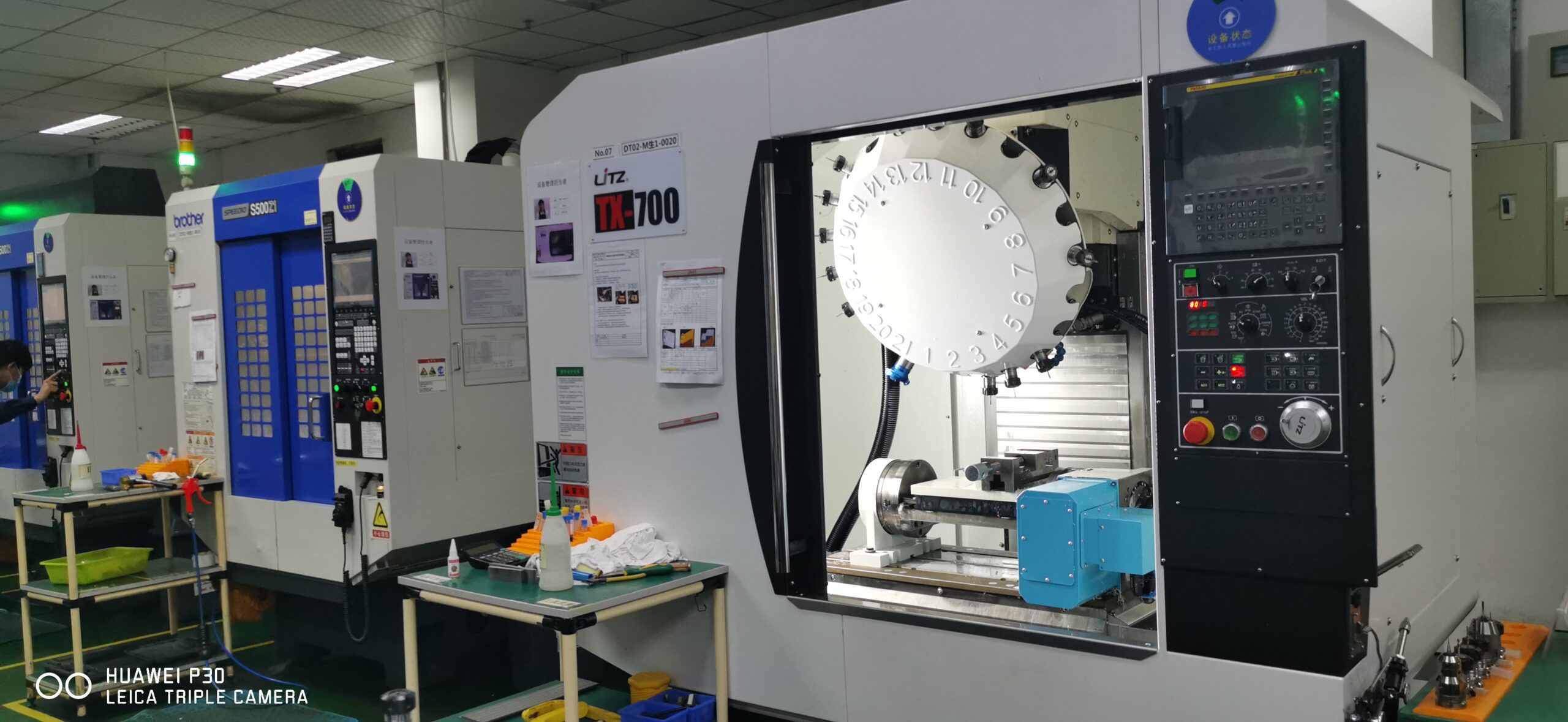

Our facility houses advanced CNC machines including 3.4.5-axis machining centers, tapping machines, drilling machines and precision grinding equipments, enabling us to handle complex geometries and high-volume production.

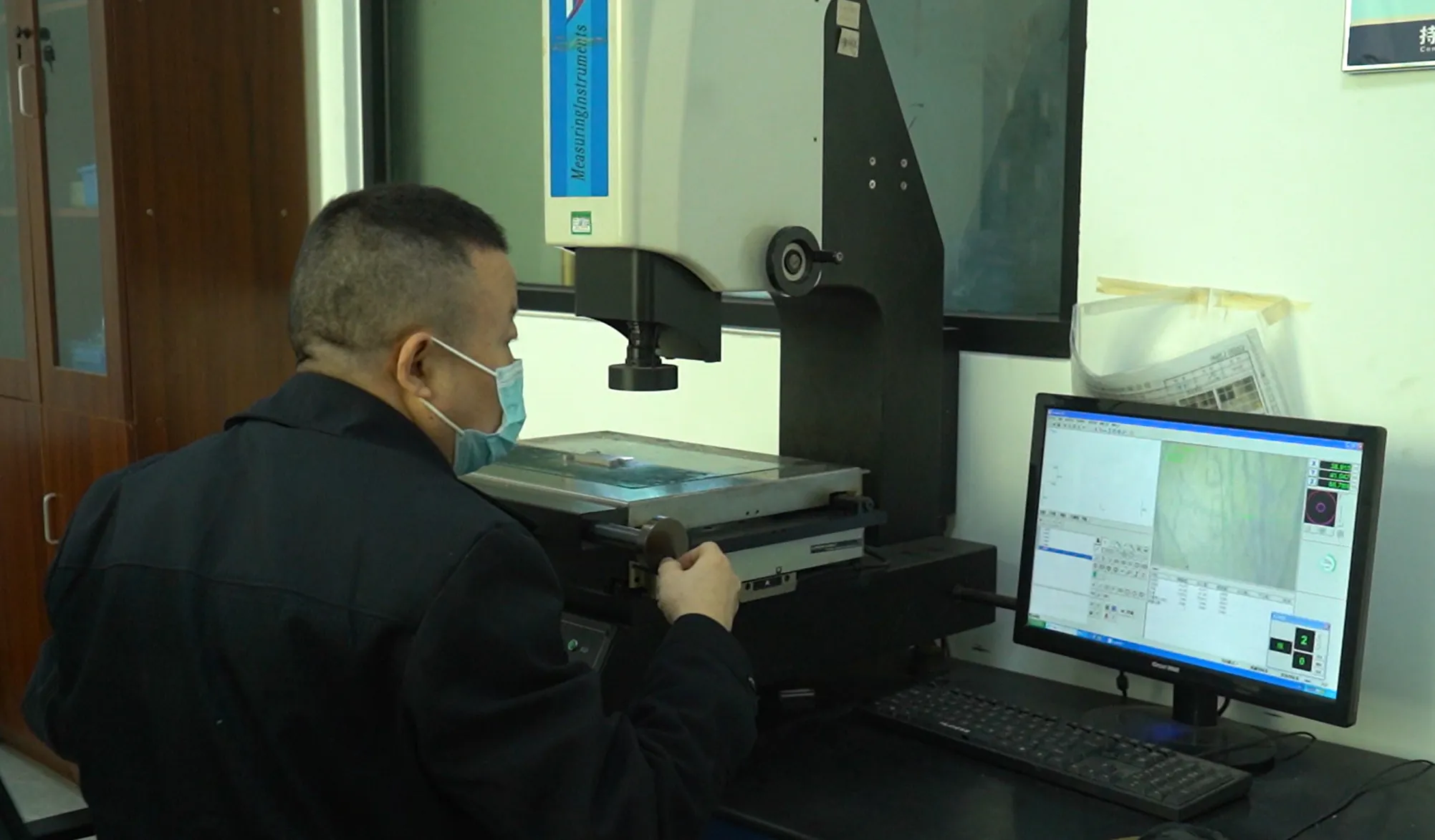

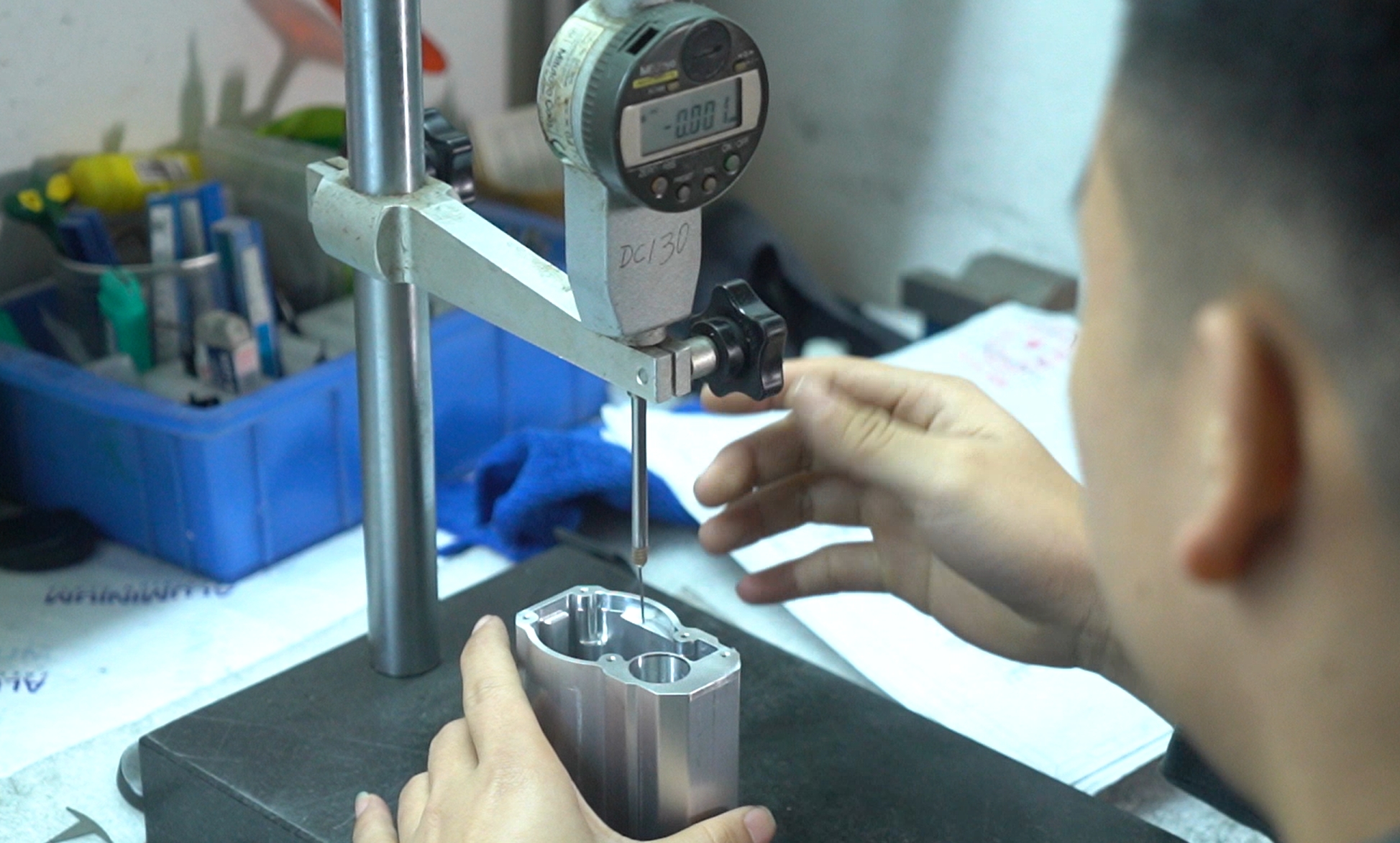

Certified to ISO 9001 standards, we implement rigorous quality control using coordinate measuring machines and optical measurement systems.

Our one-stop manufacturing capabilities include:

*Material sourcing*

*Material processing*

*Surface treatments and finishing*

* Assembly and quality documentation*

* Arrange shipping and delivery*

With an on-time delivery rate of 98% and defect rate below 0.5%, we've established partnerships with over 200 global clients across aerospace, automotive, medical device, and industrial equipment sectors.

Our engineering team collaborates with clients from concept through DFM analysis to final production, optimizing components for performance and cost-efficiency.

Our Impact in Numbers

Sunjoy CNC reach and operational excellence demonstrated through our key performance metric

500K

Annual Production Capacity

Pieces

480K

Annual Export Volume

Pieces

20+

Years of Service

Industry Experience

150+

Customers Served

Global Presence

CNC Machining Process: From Manufacturing to Delivery

Sunjoy's comprehensive CNC machining workflow ensures precision, quality, and efficiency at every stage.

Design and Engineering

Our engineering team reviews client specifications and prepares detailed manufacturing plans. We optimize designs for manufacturability while maintaining precision requirements.

- 3D model analysis

- Material selection consultation

- Tolerance verification

Material Preparation

Raw materials undergo strict quality inspection before entering production. We source high-grade materials that meet international standards and client specifications.

- Material certification verification

- Dimensional inspection

- Material cutting and preparation

CNC Programming

Our skilled programmers create optimized CNC programs using CAM software. Each program is simulated to ensure precision and efficiency before actual machining begins.

- Tool path optimization

- Machining simulation

- Program verification

CNC Machining

Our state-of-the-art CNC machines execute the programmed operations with precision up to +/-0.005mm. Experienced operators monitor the process to ensure quality and consistency.

- High-precision milling and turning

- In-process measurements

- Regular quality checks every 2 hours

Surface Treatment

Parts undergo specified surface treatments to enhance appearance, durability, and functionality. Our facility offers a wide range of finishing options to meet diverse requirements.

- Anodizing, plating, and painting

- Polishing and sandblasting

- Heat treatment processes

Quality Inspection

Our QA team conducts comprehensive inspections using advanced measuring equipment. Each part is verified against specifications before proceeding to the next stage.

- CMM (Coordinate Measuring Machine) verification

- Dimensional and geometric tolerance checks

- Surface finish inspection

Assembly

When required, components are assembled according to specifications. Our assembly team ensures proper fit and function of all assembled parts.

- Component assembly

- Functional testing

- Assembly quality verification

Packaging

Products are carefully packaged to prevent damage during transportation. We use industry-standard packaging materials and methods tailored to the specific requirements of each product.

- Custom protective packaging

- Anti-corrosion treatment

- Proper labeling and documentation

Shipping and Delivery

We coordinate with reliable logistics partners to ensure timely delivery worldwide. Our logistics team handles all necessary documentation for smooth international shipping.

- Global shipping options

- Customs documentation preparation

- Real-time tracking information

Ready to Start Your CNC Machining Project?

With 20 years of experience and ISO9001 certification, Sunjoy ensures your precision parts are manufactured to the highest standards.

Our Advanced Equipment

Explore Sunjoy's state-of-the-art manufacturing facility equipped with precision machinery to deliver exceptional quality.