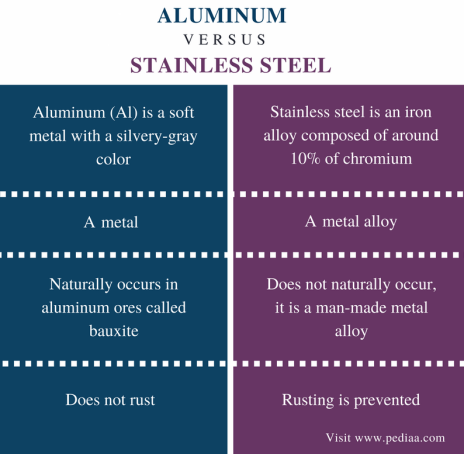

Choosing between aluminum and stainless steel for CNC projects can be mind-boggling. The stakes are high, and the wrong choice can mean wasted resources and time.

Aluminum is easier to machine than 316 stainless steel because it requires less power, is more forgiving on tools, and leads to faster production times.

Both metals have unique characteristics, but making the right choice depends on understanding their properties, costs, and project demands.

What Is Easier To Machine, 316 Stainless or 6061 Aluminum?

Machining challenges affect production schedules and budgets. You want to know which material cuts with ease and which puts pressure on your tools.

6061 aluminum is easier to machine than 316 stainless steel because aluminum is softer and requires less cutting force, leading to faster machining speeds and reduced tool wear.

When it comes to CNC machining, 6061 aluminum often takes the lead because it's softer and more pliable. This means less wear and tear on cutting tools, allowing for faster machining speeds and lower costs. The material’s properties allow for precise work without excessive wear on machines. 316 stainless steel is tougher, requiring more powerful machines and greater cutting force. Thus, it can slow down production and lead to increased maintenance costs. Here’s a quick comparison:

| Feature | 6061 Aluminum | 316 Stainless Steel |

|---|---|---|

| Machinability | High | Moderate |

| Tool Wear | Low | High |

| Cutting Force | Low | High |

| Production Speed | Fast | Slow |

| Cost | Lower tools cost | Higher tools cost |

Understanding these properties helps make an informed decision tailored to your project's needs.

How Do You Know The Difference Between Aluminum And Stainless Steel?

Observing materials can be confusing. You need a reliable way to distinguish them without relying on expert knowledge.

Aluminum is usually lighter, softer, and has a duller finish compared to stainless steel, which is heavier, stronger, and often shinier.

Identifying these metals is easier than it seems. Aluminum stands out because of its lighter weight and somewhat dull, matte finish. You're likely to notice a softer feel and greater flexibility as you handle it. In contrast, stainless steel feels dense and heavy, reflecting light with its shiny surface. These characteristics make stainless steel more suitable for strength-dependent applications. Here’s a simple method to distinguish:

- Weight: Pick it up; aluminum is noticeably lighter.

- Finish: Look for shininess; stainless steel gleams more.

- Magnet test: Most aluminum isn’t magnetic; stainless steel sometimes is (unless it's austenitic).

- Scratch test: Aluminum scratches easily; stainless steel resists.

Use these tests and observations to quickly and effectively tell these metals apart.Why choose aluminum over steel?

Aluminum often seems the go-to choice. Why would someone prefer it, especially when choosing materials for projects?

Aluminum is favored over steel for its lightweight, corrosion resistance, and cost-effectiveness, especially in industries where weight reduction is critical.

In several applications, aluminum is the hero. It’s lightweight, which is a huge advantage if reducing material stress and transportation costs is vital. This is why aerospace and automotive industries swear by it. Aluminum also ensures excellent corrosion resistance, making it apt for climates and environments prone to moisture and precipitation. The cost factor is significant; aluminum is typically less expensive than steel, making it economical for large-scale production. Here's why aluminum is preferred:

- Weight Savings: Critical in aerospace and automotive fields.

- Corrosion Resistance: Suited for marine and outdoor applications.

- Economical: Budget-friendly for mass production.

- Recyclability: High recycling rate; it's an eco-friendly option.

Choosing aluminum can be a strategic decision, balancing cost, weight, and environmental impact.How To Test If Something Is Aluminum Or Stainless Steel?

Determining the metal type seems perplexing. Nonetheless, several straightforward tests enable quick verification.

To test if something is aluminum or stainless steel, you can use the magnet test, the scratch test, or an acid test for quick identification.

This is Stainless Steel Component

There are simple ways to check if a material is aluminum or stainless steel. The magnet test is the easiest: if the magnet doesn’t stick or is weak, you’re likely dealing with aluminum, as most types of stainless steel are non-magnetic. The scratch test is useful—aluminum scratches readily. An acid test yields conclusive results: aluminum rapidly reacts with acid, changing color, while stainless steel does not. Here’s a table with the tests:

| Test | Aluminum | Stainless Steel |

|---|---|---|

| Magnet | Weak or no pull | Some pull |

| Scratch | Easy to scratch | Scratch-resistant |

| Acid | Reacts quickly | Minimal reaction |

These methods provide a quick and reliable way to identify the metals, ensuring you use the correct material for the job.

Conclusion

Choosing between aluminum and stainless steel boils down to understanding their unique properties and matching them to your project’s needs for optimal results.