5G technology promises lightning-fast speeds and robust connectivity, but what's behind this leap? Aluminum machined parts play a pivotal role.

Aluminum machined parts are indispensable in 5G base stations due to their exceptional thermal conductivity and strength-to-weight ratio. They are crucial for dissipating heat and for structural components.

The unique properties of aluminum ensure that 5G base stations operate efficiently. Its lightweight nature reduces costs and enhances performance, making it essential for large-scale deployment.

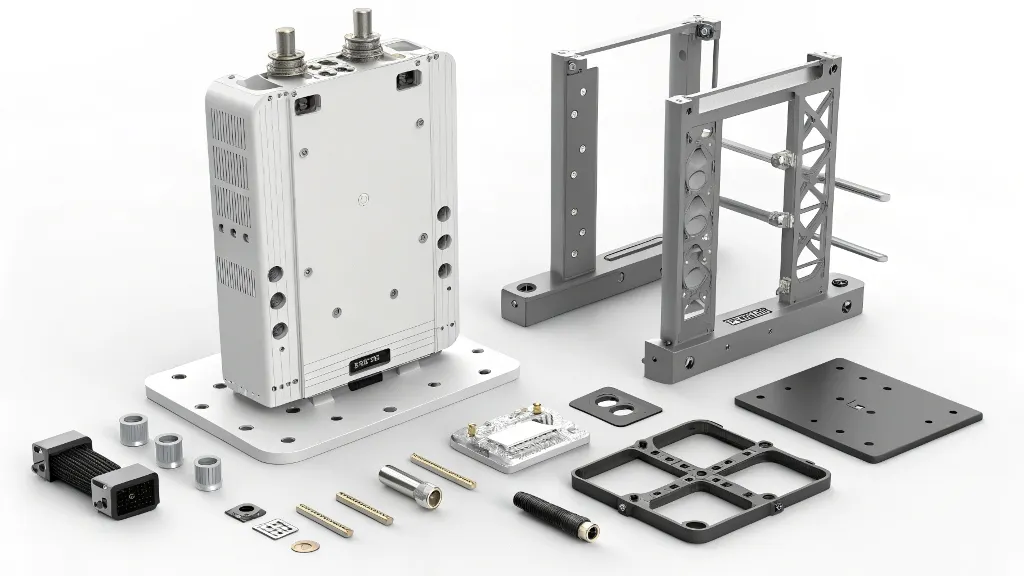

What Kind of Aluminum Machined Parts Are Used for 5G Base Stations?

In the rush to enhance connectivity, choosing the right materials is crucial. Aluminum machined parts stand out.

Aluminum is used for heat sinks, cavity filters, and antenna structures in 5G base stations, addressing both thermal management and structural needs effectively.

Delving deep into their uses, aluminum parts are tailored to meet various needs within 5G infrastructure. The ability to disperse heat effectively is crucial for the high-power chips used, preventing overheating and ensuring consistent operation. Cavity filters, crafted from aluminum, help in signal filtration, handling multiple frequencies simultaneously. The lightweight feature of aluminum also facilitates antenna designs that optimize signal penetration. The balance between durability and weight makes aluminum unmatched in this setting, ensuring both physical protection and signal clarity.

What Are the Components of the Base Station of 5G?

Every leap in technology demands finely tuned components working in harmony. 5G is no exception.

A 5G base station consists of the radio unit, distributed units, and core network connections, each part needing precise engineering to function optimally.

Breaking down further, the radio unit generates and receives electromagnetic signals, pivotal to any communication. It requires precise construction to manage high frequencies. Distributed units handle data processing, forming the backbone for quick and effective communication. Meanwhile, the core network acts as the delivery system, routing information efficiently. Each component's performance relies heavily on the construction materials used. Aluminum, with its adaptability and cost-effectiveness, often serves as a core material, ensuring these components work seamlessly together.

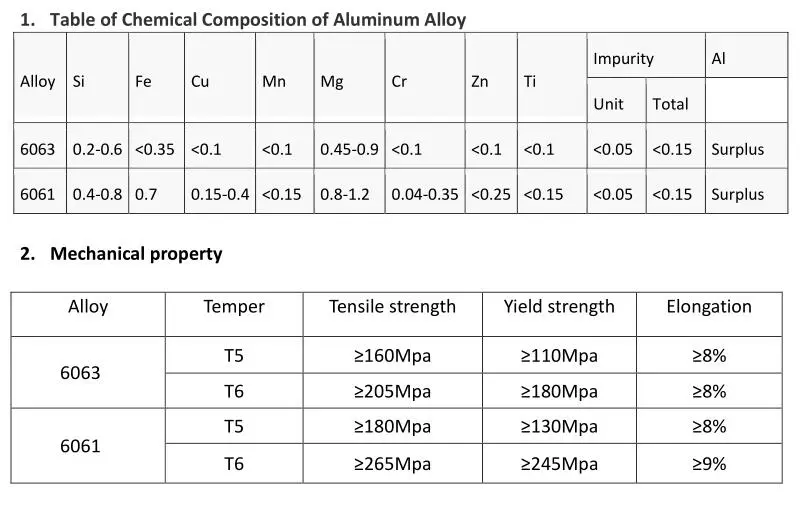

What Type of Aluminum Is Used in 5G Base Stations?

Choosing the right aluminum alloy can make all the difference in performance and durability.

High-strength aluminum alloys like 6061 and 6063 are commonly used in 5G base stations, providing excellent thermal management and corrosion resistance.

Getting deeper, not all aluminum is created equal. Alloys such as 6061 and 6063 are valued for their strength and versatility. 6061 is widely used due to its balanced properties, offering both strength and resistance to corrosion, essential for external applications. Meanwhile, 6063 is often chosen for its exceptional finishing qualities and excellent conductivity. These alloys ensure that parts withstand environmental stress, manage heat effectively, and remain cost-effective, making them ideal for the expansive deployment of 5G technology.

Conclusion

Aluminum parts are integral to 5G base stations, ensuring performance, cost-efficiency, and durability.