Precision manufacturing fascinates many with its intricate balance between artistry and engineering. But what about the machinists who make it all happen?

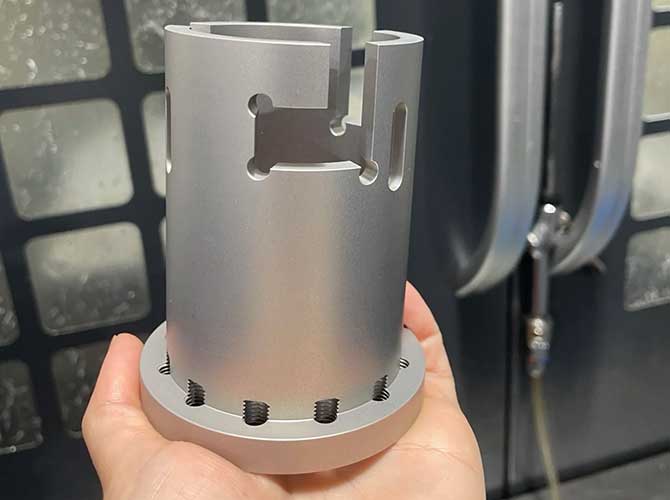

A machinist plays a crucial role in ensuring machines operate at peak efficiency. They interpret blueprints, set up machinery, check part dimension, and make precision adjustments during production. This ensures each component meets exact specifications.

Often, machinists are the unsung heroes, but their expertise in interpreting complex designs and ensuring quality is indispensable. Let's explore their world in more detail.

What Skills Define a Master Machinist?

Master machinists must possess technical expertise, hands-on experience, and creative problem-solving skills.

A master machinist needs precision, an understanding of various materials, and proficiency with advanced tools. They must execute complex operations seamlessly, ensuring every product exceeds quality standards.

Understanding a machinist's skill set requires a look into their daily challenges. They often deal with machine calibration, tool wear, and material inconsistencies. Each challenge demands analytical thinking and adaptability. Precision is paramount, particularly in industries like aerospace and automotive. Here, every fraction of a millimeter counts.

How Do Machinists Collaborate With Engineers and Designers?

Coordination between machinists, engineers, and designers is key to successful manufacturing.

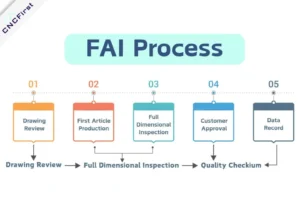

Machinists work closely with engineers and designers to bring concepts to life. Through collaboration, ideas become tangible, with machinists ensuring feasibility and functionality.

In the design phase, engineers and machinists discuss specifications. They identify potential issues or design improvements. Once production begins, the machinist’s role becomes critical. They verify designs are feasible and efficient. This ongoing communication ensures projects meet deadlines and quality standards. Miscommunication can lead to costly errors, highlighting the importance of clear dialogue.

Why Is Continuous Learning Essential in This Field?

The ever-evolving nature of technology means machinists must regularly update their skills.

Continuous learning is essential. Machinists must stay ahead by learning new technologies, techniques, and materials.

The world of manufacturing is dynamic. New materials, CNC machines, and software frequently emerge. Staying current is not optional; it's necessary for machinists aiming for excellence. Workshops, certifications, and training programs are crucial for skill enhancement. Those investing in learning become invaluable assets to their organizations. This commitment to growth not only benefits machinists but also ensures industry competitiveness.

Conclusion

Machinists are the backbone of precision manufacturing, blending expertise with innovation, ensuring every component is crafted to perfection.