The adoption of 5G technology demands precision engineering. CNC machined components offer reliability but can they withstand harsh conditions and ensure longevity?

Yes, CNC machining components are crucial for 5G base stations. They provide precise and durable parts capable of performing in challenging environments, essential for sustained use.

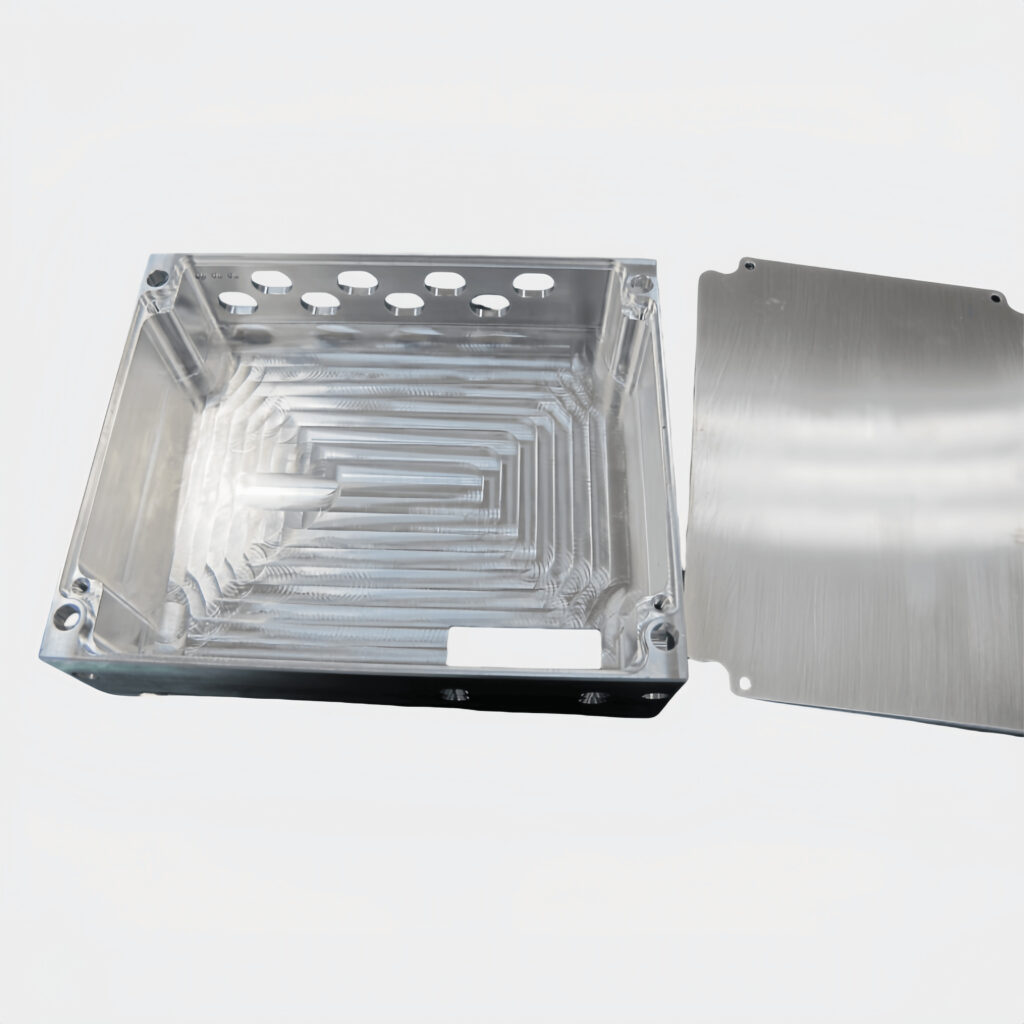

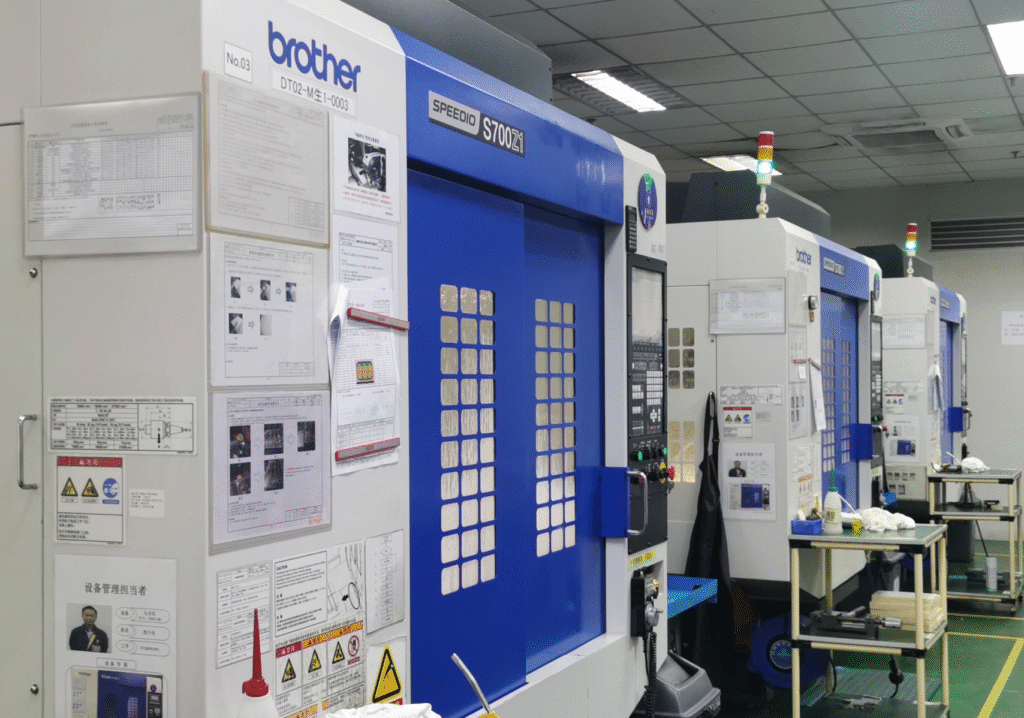

CNC machining offers significant advantages for 5G base station components. It ensures ultra-high precision for critical parts like antenna arrays and filters, which is essential for optimal signal transmission at millimeter-wave frequencies. The process also delivers excellent thermal management features, durability, and repeatability, supporting the rigorous demands and mass production of 5G infrastructure.

What are the components of the base station of 5G?

Base stations are complex with various critical parts. How do these parts come together?

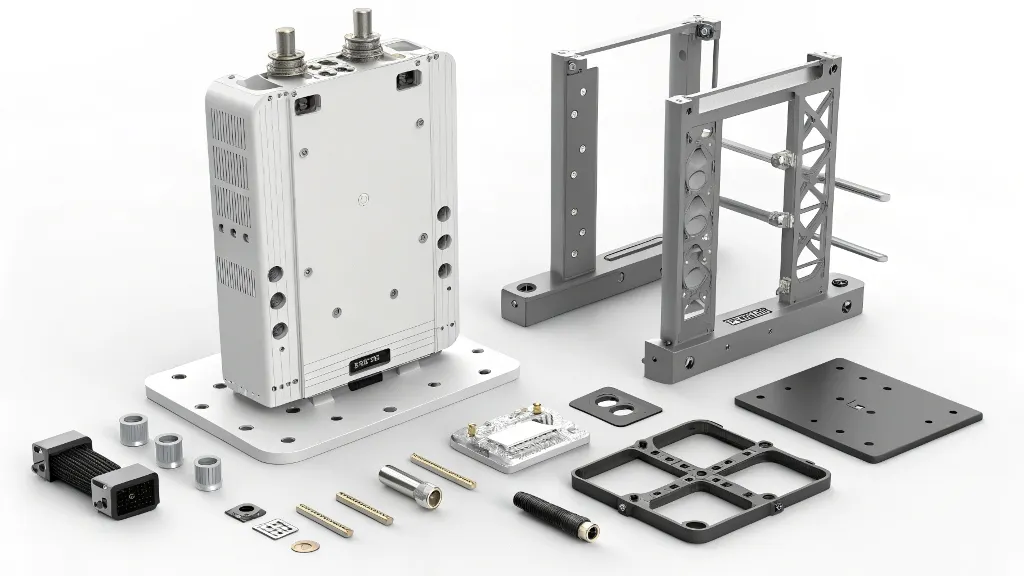

A 5G base station includes antennas, transmitters, receivers, cooling systems, and integrated hardware essential for transmitting high-frequency signals effectively.

Breaking down the base station's composition shines a light on its intricacy. Antennas capture signals, while transmitters and receivers handle their dispatch. Cooling systems ensure the equipment remains functional under constant operation. CNC machining provides accuracy in producing these components, ensuring every piece fits perfectly. This precision directly affects performance, making CNC machining indispensable.

Which 5G components are produced via CNC machining?

Precision is crucial in 5G technology. Which parts derive this accuracy from CNC machining?

CNC machining produces waveguides, mounting brackets, and heat sinks, which require meticulous precision. They ensure high performance and longevity under diverse conditions.

Waveguides are paramount in routing waves between devices. Mounting brackets secure equipment, playing an unseen yet vital role. Heat sinks dissipate heat, maintaining optimal temperature levels. All three involve intricate designs needing precise cuts and finishes, achievable only through CNC machining. This precision improves performance, crucial for maintaining signal integrity and equipment longevity.

What metal material is used for 5G base station?

Material selection impacts both performance and durability. What metals fit this high-demand role?

Aluminum alloys, stainless steel, and copper are commonly used. They offer corrosion resistance, conductivity, and strength—fitting the rigorous requirements of 5G base stations.

Aluminum alloys are lightweight yet robust, making them ideal for mounts and cooling systems. Stainless steel provides strength and resistance to corrosion, crucial for external parts facing environmental exposure. Copper's exceptional conductivity makes it perfect for components dealing with signal transmission. Selecting the right material ensures the base station operates efficiently, withstands harsh elements, and lasts longer.

What is the tolerance of CNC machining for 5G base station components?

Tolerances impact performance significantly. How precise is CNC machining when crafting 5G components?

CNC machining for 5G components typically deals with tolerances ranging from ±0.005 mm to ±0.02 mm, ensuring exact fits and optimal performance.

Tolerances dictate how closely parts adhere to designed specifications. For 5G components, even minor deviations can affect signal quality or component longevity. CNC machining offers high precision, shaping parts to exact dimensions needed for seamless integration. Maintaining stringent tolerances ensures reliability, crucial in the fast-paced, high-stakes domain of 5G technology.

Conclusion

CNC machining's precision crafts the resilient components vital for 5G base stations, ensuring performance and durability under challenging conditions.