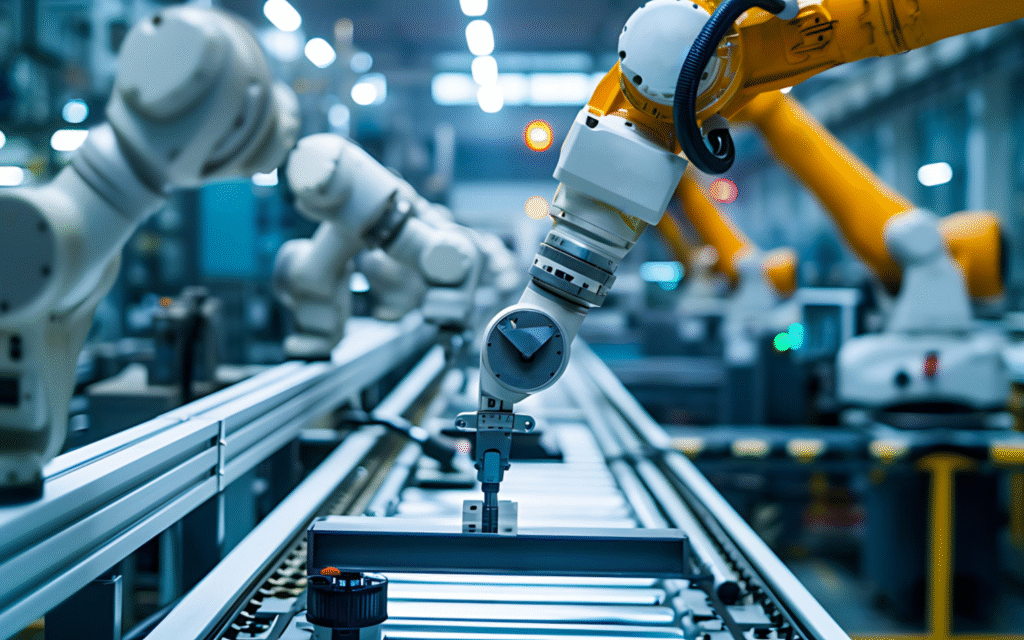

Precision turned components are crucial for robotics, ensuring that parts fit and function seamlessly. Missed tolerances can lead to failures in robotic operations.

Precision turned components are essential for robotics projects, providing accuracy in assembly and operation. They ensure reliability by maintaining tight tolerances necessary for robot functionality.

Precise components are the backbone of effective robotic systems. Their importance lies in optimizing functionality, reducing errors, and ensuring efficient motion control. Robotics demand these precision elements to work harmoniously in complex assemblies.

What is the best metal for robotics?

Choosing the right metal is key. Common choices like aluminum and steel offer different advantages for robot construction and efficiency.

The best metal for robotics depends on the application. Aluminum is lightweight and versatile, while steel provides strength and durability, crucial for structural components.

Metals in robotics must meet specific criteria. Aluminum, with its lightweight nature, reduces energy consumption and enhances speed. Steel, on the other hand, offers robustness, ideal for parts enduring significant stress. Each has unique properties which engineers must weigh according to project needs. Tables like the one below can help visualize and compare these elements:

| Metal | Properties | Best Use |

|---|---|---|

| Aluminum | Lightweight | Fast, agile robots |

| Steel | Durable, strong | Heavy-duty structural parts |

What is precision in robotics?

Precision makes robotics effective. It refers to the accuracy and exactness of movements and assembly, vital for task execution.

Precision in robotics ensures component alignment and movement accuracy, crucial for performing tasks and maintaining efficiency. It's the backbone of robotic functionality.

Precision is indispensable in robotics. It ensures components move correctly and tasks are executed flawlessly. This involves accurately programmed movements and detailed assembly, allowing robots to perform complex tasks without error. Engineers use advanced tools to measure and maintain this precision, critical for high-performance robotics.

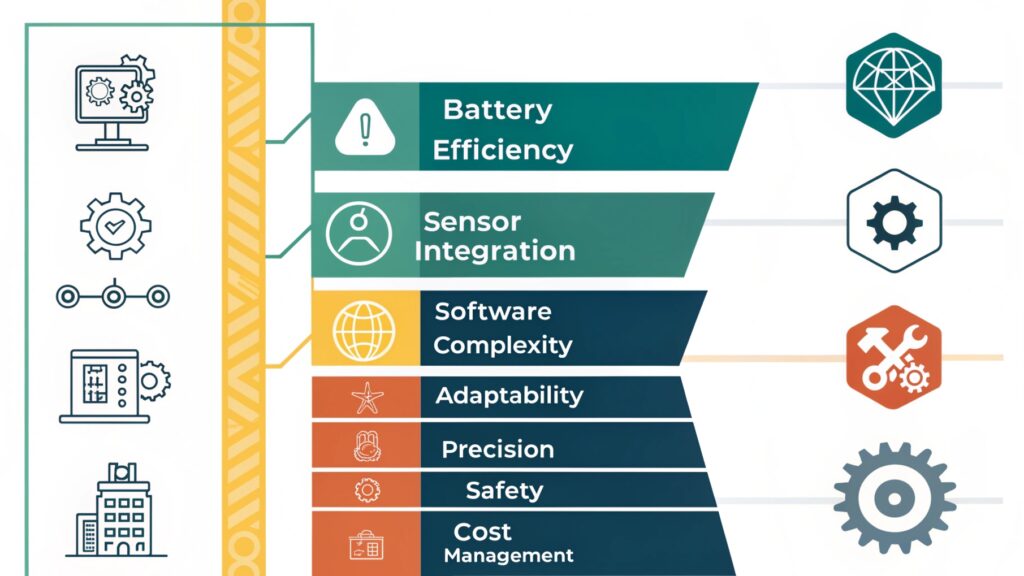

What are the 7 biggest challenges in robotics?

Robotics face hurdles that shape its development. Identifying major challenges helps navigate towards effective solutions.

The biggest challenges in robotics include battery efficiency, sensor integration, software complexity, adaptability, precision, safety, and cost management. Each impacts system performance.

Robots contend with a variety of challenges. Battery life restricts operational hours, while sensor integration determines accuracy in perception. Software issues can lead to complexity in controls. Adaptability requires flexible programming to respond to dynamic environments. Precision, as discussed, is vital for task accuracy. Safety protocols must be robust to handle unexpected interactions, and cost management is needed to ensure economic viability. Each challenge needs strategic approaches to enhance robotics performance.

Can robots execute tasks with high precision?

Robots are expected to perform precise tasks. Understanding their capability helps enhance operation effectiveness.

Yes, robots can execute tasks with high precision. Advances in technology ensure accurate movement and component operation, essential for complex task execution.

The precision of robots is a testament to technological advancements. With fine-tuned programming, robots can handle tasks that require repeatability and accuracy. This includes finely-tuned manipulators and advanced sensors integrating feedback loops. Such precision is crucial for industries like manufacturing, healthcare, and research, where accuracy determines success and efficiency. Engineers strive to push these boundaries further, ensuring robots can meet ever-growing demands.

Conclusion

Precision turned components are vital for robotics, enhancing functionality and accuracy across projects.