The complexity of box build assemblies can be overwhelming, with various components needing precise integration.

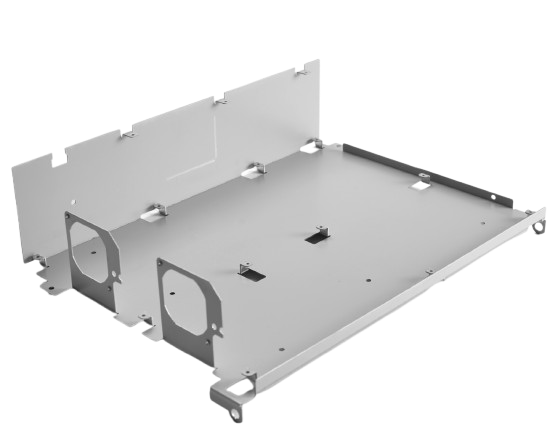

Sheet metal stamping is integral in electronics manufacturing, especially for box build assemblies. It involves transforming flat metal sheets into specific shapes through cutting, bending, and forming, providing sturdy and reliable enclosures for electronic components.

While sheet metal stamping is crucial, understanding other components is necessary for a holistic approach to box builds.

Except Sheet Metal Stamping, What Else Metal Parts Are Used in Box Building Assembly?

In electronics manufacturing, other metal parts play vital roles beyond just enclosures, increasing both efficiency and performance.

Heatsinks and fasteners are common metal parts used in box build assembly. Heatsinks dissipate heat from electronic devices, while fasteners ensure secure assembly of components.

Heatsinks are often made from aluminum or copper due to their excellent thermal conductivity. Fasteners vary in materials, usually steel or stainless steel, based on the application's strength and corrosion resistance needs.

| Component | Material | Function |

|---|---|---|

| Heatsink | Aluminum/Copper | Dissipate heat |

| Fasteners | Steel/Stainless | Secure components |

These parts are essential in handling thermal management and maintaining assembly integrity.

Which Metal Is Used in Making Metal Boxes?

Choosing the right metal for electronic housings is crucial for performance and longevity.

Aluminum is widely used for making metal boxes due to its lightweight, durable, and corrosion-resistant nature.

Aluminum’s thermal conductivity ensures efficient heat dissipation, essential for protecting sensitive electronic components. Furthermore, its ease of fabrication allows for cost-effective production while maintaining structural integrity, making it a preferred choice in various electronic applications.

What Can Sunjoy Do for Box Building Assembly?

Sunjoy excels in providing high-quality solutions, combining technical precision with innovative approaches in manufacturing.

Sunjoy offers comprehensive services for box building assemblies, including CNC machining and precision sheet metal fabrication.

With expert engineers and state-of-the-art technology, Sunjoy can customize and optimize designs to meet specific customer requirements. This includes machining, welding, and assembly processes to ensure every product meets strict quality standards.

What is Sunjoy's Core Competence?

Understanding Sunjoy's strengths helps leverage their services for optimal results in manufacturing projects.

Sunjoy's core competence lies in its experience and expertise in CNC and die-casting manufacturing.

Founded by Alan Dong, Sunjoy combines deep industry knowledge with cutting-edge technology. Their dedication to quality and innovation sets them apart, making them a reliable partner in the electronics manufacturing sector. Their focus on customer satisfaction ensures they deliver solutions tailored to specific project needs.

Conclusion

Mastering sheet metal stamping and other components can greatly enhance box build assembly success in electronics manufacturing.