Corrosion can destroy machines, leading to costly repairs and downtime. This is why picking the right CNC material for corrosion resistance is crucial.

Selecting the right CNC material ensures long-lasting performance by preventing damage from moisture or chemicals. Common options include stainless steel, aluminum, and titanium for their excellent corrosion resistance.

It's essential to understand how different materials react with varying environments to make a well-informed choice. Below, we'll explore various materials and their properties to help you decide.

Why is stainless steel a popular choice for corrosion resistance?

Stainless steel is renowned for its durability and resistance to both wear and corrosion. This makes it an excellent choice for environments exposed to moisture.

Stainless steel's corrosion resistance comes from the chromium content, which forms a protective layer on the surface. This layer prevents rust and maintains the material's integrity even in harsh conditions.

Exploring Stainless Steel Options

Stainless steel comes in different grades, each suited for specific applications. For instance, 304 stainless steel is common for its general corrosion resistance, while 316 stainless steel offers enhanced resistance in marine environments due to higher molybdenum content. Knowing the differences and applications is key when choosing the right grade for your project.

| Grade | Composition | Best Use Cases |

|---|---|---|

| 304 | Chromium | General environments |

| 316 | Molybdenum | Marine environments |

| 430 | Nickel-free | Budget-friendly applications |

By tailoring your choice to your specific environment, stainless steel keeps your CNC components functional and durable.

How does aluminum offer corrosion resistance benefits?

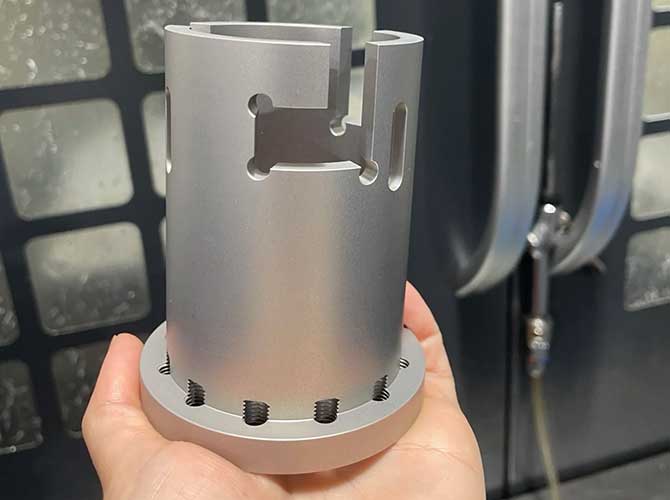

Aluminum is lightweight yet offers significant corrosion resistance, making it perfect for various applications, especially in electronics and transport.

Aluminum naturally forms an oxide layer that acts as a barrier against corrosion. This property means lower maintenance costs and longer-lasting performance for CNC machined parts.

Understanding Aluminum Alloys

Various aluminum alloys are available, each with unique attributes. For example, 6061 aluminum is a versatile choice for its strength and corrosion resistance, while 5052 is excellent for marine applications due to its magnesium content. Knowing these details helps you pick the right alloy for specific conditions.

| Alloy | Composition | Key Features |

|---|---|---|

| 6061 | Magnesium | Versatile, good strength |

| 5052 | Magnesium | Excellent for marine use |

| 7075 | Zinc and copper | High strength, aerospace sector |

Choosing the right aluminum alloy ensures parts that withstand the intended environment effectively.

Is titanium worth the investment for extraordinary resistance?

Titanium is known for exceptional corrosion resistance and strength. It's often selected for critical applications where other materials might fail.

Though more expensive, titanium provides outstanding durability. It resists almost all types of corrosion, hence is ideal for aerospace, medical, and chemical industries.

Evaluating Titanium's Advantages

Titanium's remarkable properties stem from its ability to form a dense oxide layer that protects against a wide range of physical and chemical hazards. Despite its cost, its longevity and superior performance in challenging environments make it a top choice for sensitive applications.

| Property | Description |

|---|---|

| Strength | High strength-to-weight ratio |

| Durability | Resists various corrosive elements |

| Usability | Suitable for diverse extreme settings |

Choosing titanium ensures investment in quality and reliability, particularly for critical needs.

Conclusion

Selecting the right CNC material is crucial for corrosion resistance. Stainless steel, aluminum, and titanium offer distinct benefits, catering to diverse application needs.