Designing decorative lamps can be challenging when deciding between materials like CNC brass and stainless steel. These choices impact aesthetics, cost, and durability.

CNC brass offers a warm, classic look ideal for decorative lamps, while stainless steel provides modern elegance and robust durability. Choosing depends on design needs and environment.

Which material is best suited for your decorative lamp project? Discover important aspects to consider by exploring the characteristics and benefits of each option.

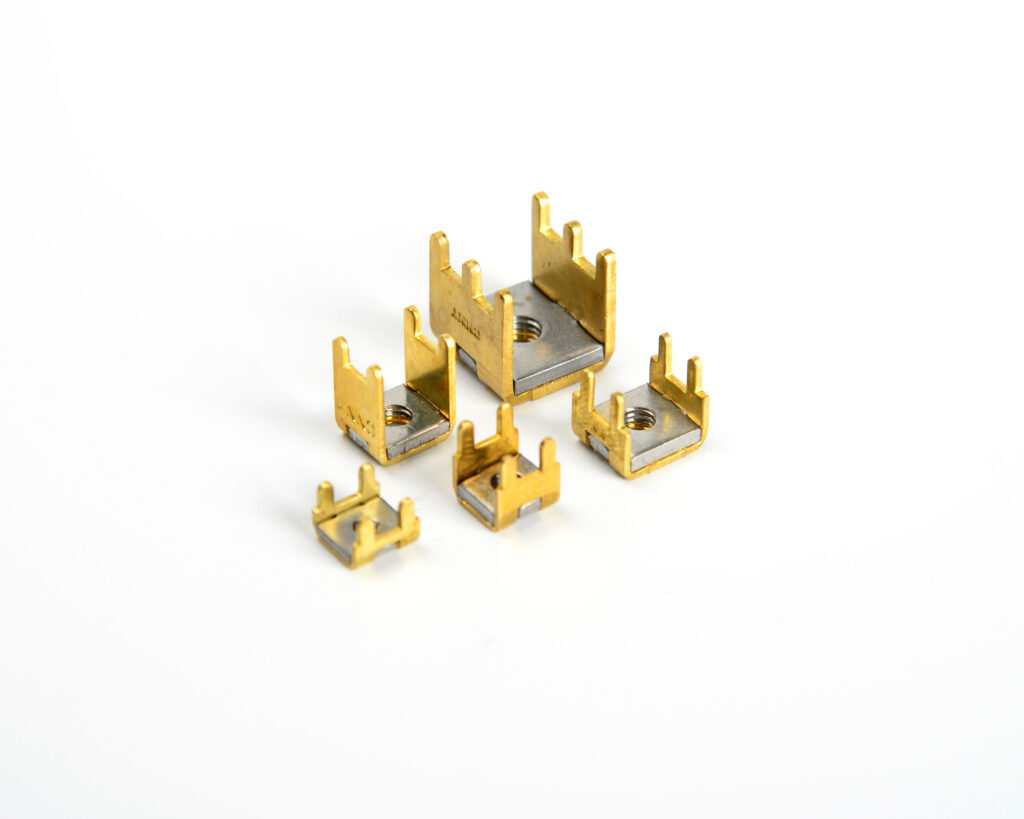

Why Choose CNC Brass for Decorative Lamps?

CNC brass brings warmth and elegance to decorative lamps, making it a favorite for many designers. Its golden sheen adds a luxurious touch.

Brass is ideal for intricate designs due to its malleability. It's corrosion-resistant and provides an antique appeal suitable for classic and traditional designs.

Understanding CNC brass's properties helps in creating distinguished and long-lasting lamp designs. With its ease of shaping, brass allows for detailed work without compromising structural integrity. Designers can achieve both vintage and contemporary looks by combining brass finishes with modern elements. Here’s a simple breakdown:

| Feature | Description |

|---|---|

| Appearance | Warm, golden sheen |

| Durability | Good, with corrosion resistance |

| Workability | High, allows for detailed designs |

Stainless Steel: A Durable Alternative?

Stainless steel offers a sleek and modern look for decorative lamps, appealing to those favoring minimalist designs. It's known for its strength and longevity.

Its resistance to corrosion and tarnishing makes it suitable for both indoor and outdoor applications. It maintains its appearance for years with minimal maintenance.

| Explore how stainless steel’s durability complements modern design needs. By choosing stainless steel, designers ensure that their lamps remain resilient to environmental wear and fit various thematic aesthetics. The reflective nature of stainless steel can also add visual interest in well-lit spaces. Here’s a detailed overview: | Feature | Description |

|---|---|---|

| Appearance | Sleek, modern | |

| Durability | Excellent, highly resistant to corrosion | |

| Workability | Moderate, suitable for simpler designs |

Comparing Costs: What Should You Consider?

Selecting materials often involves weighing cost against design goals. Both brass and stainless steel have cost implications.

Brass typically incurs higher costs due to its aesthetic appeal and workability. Stainless steel could be more budget-friendly given its resistance to wear.

When deciding on costs, consider the long-term benefits and aesthetic value. Brass might be pricier initially, but its classic charm can add value, whereas stainless steel offers durability and cost efficiency. Here is a cost comparison:

| Material | Initial Cost | Long-term Benefits |

|---|---|---|

| Brass | Higher | Aesthetic, longevity |

| Stainless Steel | Moderate | Durability, low upkeep |

Are Environmental Factors Influential?

Material choice must account for the environment in which the lamp will reside. Each material responds differently to environmental stressors.

Brass suits indoor settings with controlled climates while stainless steel excels in varied environments, including high humidity areas.

Understanding how the environment influences material performance aids informed decision-making. In coastal areas, for example, stainless steel may withstand exposure better than brass. Consider these environmental factors:

| Factor | Brass Suitability | Stainless Steel Suitability |

|---|---|---|

| Humidity | Moderate | High |

| Temperature | Moderate | High |

Conclusion

Choosing between CNC brass and stainless steel for decorative lamps hinges on design preference, cost, and environmental considerations.