In the world of amplifier production, precision matters. Ever wondered which amplifier parts can be efficiently processed using CNC machines?

Amplifier parts like chassis, heatsinks, connectors, knobs and front panels can be produced using CNC machining. This method ensures high precision, ideal for intricate designs and functionality required in amplifier components.

Amp production demands perfection. To capture precision, CNC machining stands out. It shapes components like knobs and panels with exacting standards, ensuring quality. Dive in with me to explore further what CNC can do for your amp design.

What surface treatment is better for amplifier?

Surface treatments affect durability and appearance. Ever puzzled over which coating offers the best protection for amplifiers?

Anodizing is a superior surface treatment for amplifiers. It provides durability, corrosion resistance, and an appealing finish—essential qualities for high-performance audio equipment.

| Anodizing is a staple in my amplifier projects. It's more than a protective layer; it's an enhancement of appearance. Various methods exist to treat amplifier surfaces, but anodizing offers a blend of strength and beauty. Let's break it down in a structured way: | Surface Treatment | Durability | Appearance | Application Ease |

|---|---|---|---|---|

| Anodizing | High | Attractive | Moderate | |

| Powder Coating | High | Varied | Easy | |

| Plating | Medium | Glossy | Complex |

This table illustrates why anodizing is my go-to for amplifiers. Its balance between robustness and aesthetics makes it ideal for professional gear.

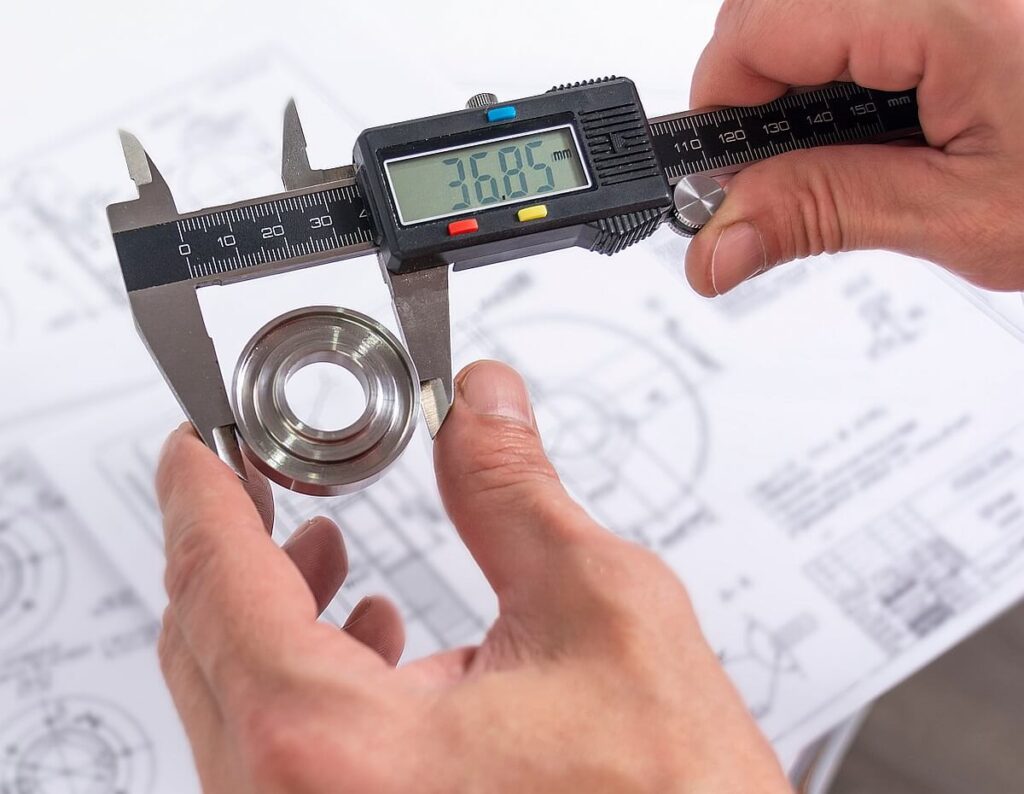

What is the tolerance for amplifier?

Tolerance is key in component functionality. How precise must amplifier parts be to ensure seamless integration?

Amplifier components require tolerances commonly within ±0.05 mm. This ensures parts fit and function as intended, maintaining audio quality and structural integrity.

When producing amplifier parts, precise tolerances ensure that everything fits perfectly and functions as expected. Tighter tolerances often mean better overall quality. To me, getting these exact measurements is a hallmark of success in product design. Let's explore the intricacies:

| Component | Typical Tolerance (mm) | Role in Amplifier Function |

|---|---|---|

| Knobs | ±0.02 | Control precision |

| Front Panels | ±0.03 | Structural integrity |

| Connectors | ±0.05 | Electrical connectivity |

Each element's tolerance contributes to the overall sleek operation. These standards are crucial, as they affect audio delivery and device durability.

What is Sunjoy's quality system?

Quality systems define success. How does Sunjoy assure excellence in amplifier component manufacturing?

Sunjoy employs a rigorous quality system incorporating ISO standards. This ensures each component meets stringent criteria for reliability and performance in amplifier production.

Quality is the backbone of my work at Sunjoy. From careful inspections to precise machining, ensuring every part aligns with our exacting standards is essential. Our process includes:

- Inspection Protocols: Detailed checks at every stage of production.

- ISO Standards: Compliance with international quality benchmarks.

- Continuous Improvements: Feedback loops for perpetual refinement.

This systematic approach is what sets Sunjoy apart in the competitive landscape of amplifier manufacturing.Can Sunjoy assemble amplifiers?

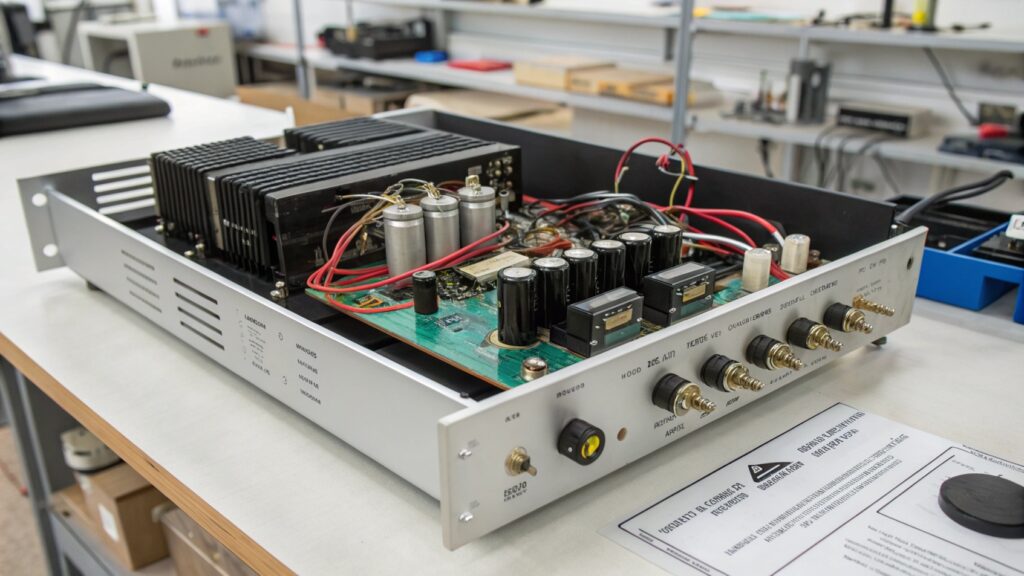

Assembly completes the puzzle. Can Sunjoy transform precision parts into finished amplifiers?

Sunjoy provides assembly services for amplifiers, leveraging expertise in component integration and production, ensuring complete functionality and aesthetic quality.

At Sunjoy, we don’t just create parts; we build finished amplifiers. Bringing CNC machined pieces together is about harmony and precision. Each step is planned to ensure products are robust and ready for market. The assembly service includes:

- Detailed Assembly Plan: Ensuring each part works together flawlessly.

- Testing Procedures: Verifying every amplifier for optimal performance.

- Logistics Management: Efficient handling and delivery to clients.

Sunjoy’s assembly process is a testament to our dedication to quality and innovation.Conclusion

Sunjoy elevates amplifier manufacturing, blending CNC precision, anodizing durability, exact tolerances, quality systems, and professional assembly into unrivaled products.