I always wondered how accurate CNC machining really is. It's a question that comes up a lot in product design. What level of precision can we actually achieve?

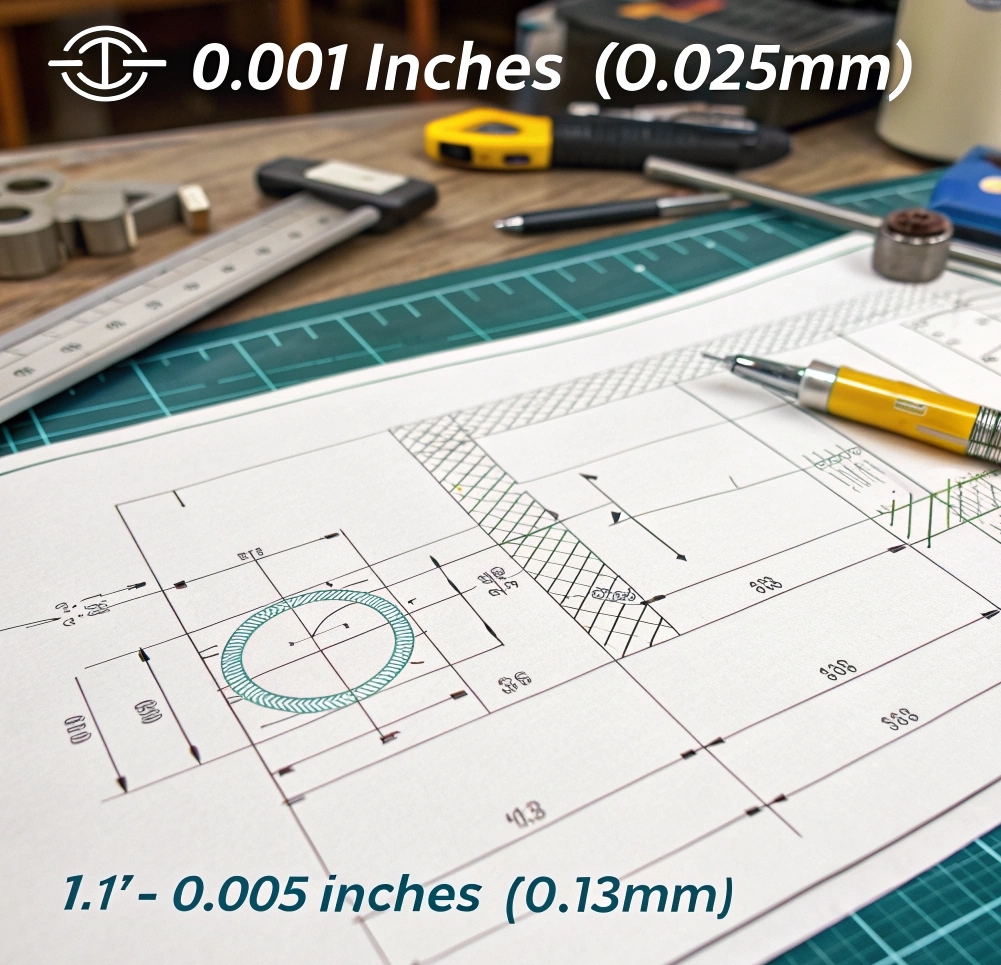

CNC machining can typically achieve a standard tolerance of +/- 0.13mm (0.005"). However, with specialized setups and techniques, it's possible to reach even tighter tolerances, down to +/- 0.01mm (0.0004") or even finer in some cases.

So, you're probably thinking, "Okay, but what does that really mean for my project?" Let's dig a bit deeper.

What is the tolerance for CNC precision?

Worried about whether your parts will fit together perfectly? CNC tolerance tells you how much wiggle room there is. It's crucial for ensuring everything works smoothly.

Tolerance in CNC machining is the acceptable range of variation in a part's dimensions. Standard tolerances are generally around +/- 0.13mm (0.005 inches). Tight tolerances, requiring more precision, can go down to +/- 0.025 mm (0.001 inches) or even finer.

Tolerance is super important because it affects how well parts fit together. If the tolerance is too loose, parts might not assemble correctly, leading to rework or unusable products. On the other hand, overly tight tolerances can drive up costs and lead times unnecessarily. Finding the right balance is key!

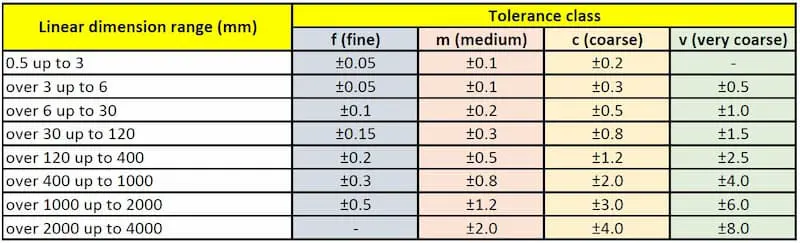

There are different types of tolerances used in CNC machining, including:

- Standard Tolerances: These are typical tolerances used for commonly manufactured parts, often around +/- 0.1mm (0.004").

- Limit Tolerances: These specify a range of acceptable values, with upper and lower limits. For example, a dimension might be specified as 15 - 15.5mm.

- Unilateral Tolerances: These allow variation in only one direction, either positive or negative.

- Bilateral Tolerances: These allow variation in both positive and negative directions from the nominal value.

- Geometric Dimensioning and Tolerancing (GD&T): This is a standardized system that uses symbols to define allowable variations in form, orientation, location, and size of part features.

Understanding these different types of tolerances is essential for communicating your design requirements effectively.

How precise can a CNC machine be?

Ever wondered just how accurate those CNC machines really are? The answer might surprise you. It all comes down to the machine's capabilities.

CNC machines can be incredibly precise. Some can achieve accuracies as high as +/- 0.005mm. However, achieving this level of precision is often expensive and time-consuming.

The precision of a CNC machine depends on several factors, including the machine's quality, its maintenance, and the expertise of the operator. High-precision machines, like ultra-precision lathes and 5-axis milling centers, are capable of achieving extremely tight tolerances. To achieve these tolerances consistently, several factors must be considered:

- Machine type: Ultra-precision lathes and 5-axis milling centers are capable of achieving the tightest tolerances.

- Material behavior: Different materials expand and contract at different rates, which can affect tolerance stability.

- Part complexity: Complex parts often require more setups and specialized tooling, which can impact precision.

- Tooling: Sharp, high-quality cutting tools are essential for maintaining dimensional accuracy. Dull or worn tools can cause inaccuracies.

- Environmental control: Maintaining a stable temperature and humidity is crucial for preventing thermal expansion and contraction.

What is the highest tolerance for machining?

Pushing the limits of what's possible? When it comes to machining, just how tight can tolerances get? The answer depends on the application.

The highest tolerance for machining can reach +/- 0.0005 inches (0.0127mm) or even better under highly controlled conditions. These ultra-precise tolerances are usually reserved for critical applications in aerospace, defense, and medical fields.

Achieving the highest possible tolerance requires a combination of advanced equipment, skilled operators, and careful process control. It's important to remember that tighter tolerances generally mean higher costs and longer lead times. This is because achieving these levels of precision requires more machine time, finer tools, additional quality inspections, and sometimes even custom fixturing.

When deciding whether to pursue extremely tight tolerances, consider the following:

- Is the tight tolerance truly necessary for the part's function? Over-specifying tolerances on non-critical features can lead to wasted effort and budget.

- What material are you using? Some materials are more difficult to machine to tight tolerances than others. For example, soft plastics can be challenging due to deformation or thermal instability.

- What are the specific requirements of your application? Industries like aerospace and medicine often require extremely tight tolerances to ensure the safety and reliability of their products.

What are the realistic tolerances for machining?

Dreaming of perfect parts? Let's get real. What tolerances can you actually expect in a typical machine shop? It's about balancing precision with practicality.

Realistic tolerances for machining generally fall in the range of +/- 0.005 inches (0.13mm). This is a standard tolerance that most machine shops can achieve consistently and cost-effectively. For tighter tolerances, +/- 0.001 inches (0.025mm) is achievable with more advanced techniques.

As someone with over 10 years of experience in CNC and die-casting manufacturing, I know that choosing realistic tolerances is about balancing precision with cost and manufacturability. Here are some tips for achieving realistic tolerances in your machining projects:

- Consider the material: Softer materials like aluminum are generally easier to machine to tight tolerances than harder materials like stainless steel. In my experience, aluminum is easier to control than stainless steel.

- Choose the right machining process: Different machining processes have different capabilities. For example, CNC milling typically offers tighter tolerances than turning.

- Work with an experienced machinist: A skilled machinist can help you optimize your design and machining process to achieve the desired tolerances.

- Communicate your requirements clearly: Be sure to clearly specify your tolerance requirements on your drawings and communicate them to your machinist.

- Don't over-specify tolerances: Only specify tight tolerances where they are truly necessary for the part's function.

In my experience, we can typically achieve tolerances of +/- 0.01mm. It's important to remember that tolerances for stainless steel can be more difficult to control than for aluminum.

Conclusion

CNC machining offers impressive precision. Understanding realistic tolerances helps balance quality, cost, and manufacturability.