CNC Machining quality issues can undermine even the most promising designs. This is where First Article Inspection (FAI) steps in as a vital checkpoint.

First Article Inspection (FAI) is a process where a part’s compliance with engineering specifications is verified. It ensures quality from the start, preventing costly errors and ensuring consistency in production.

Understanding the importance of FAI not only saves money but also enhances a manufacturer's reputation for reliability and precision.

What is the First Article Inspection (FAI)?

It’s not just a check—FAI is your assurance that the CNC metal part meets stringent standards right from the first production run.

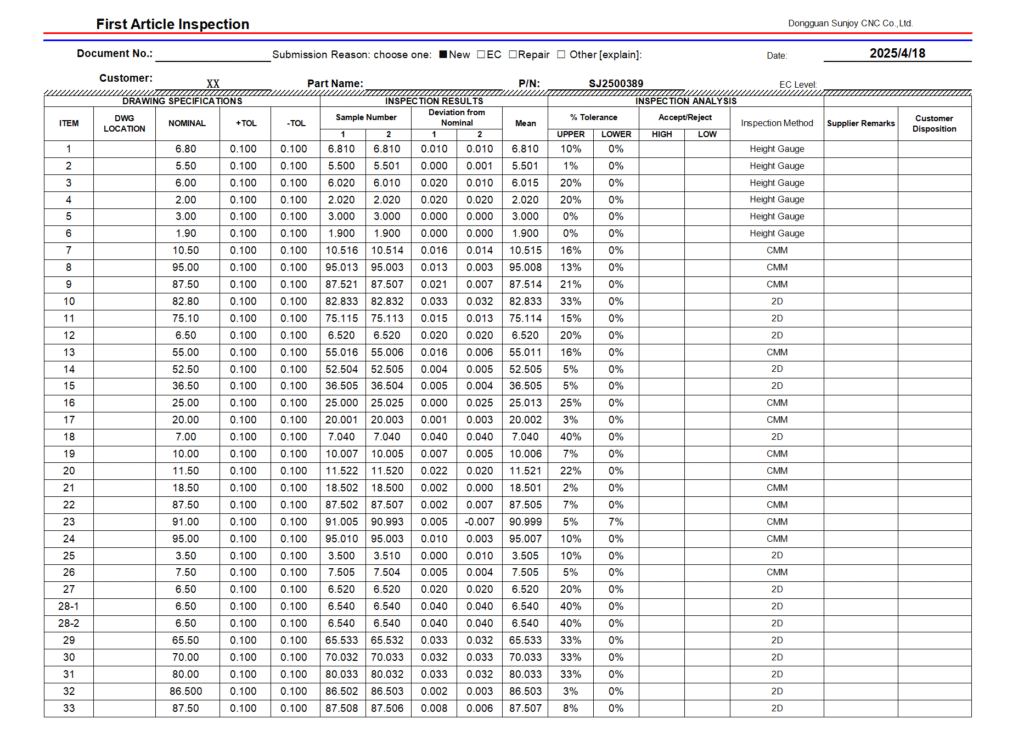

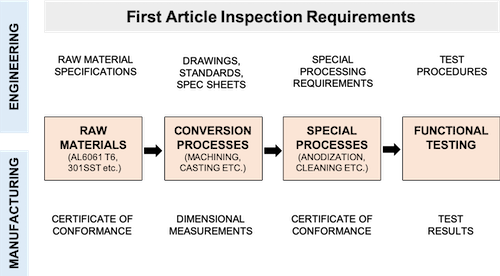

FAI involves a detailed verification and validation process where a sample from the first production run is thoroughly checked against design specifications to ensure it meets quality standards before full-scale production begins.

Dig deeper into FAI, and you'll find it's about building a bridge between design and manufacturing. During FAI, every characteristic of the prototype is measured, compared with the design blueprint, and documented. This ensures that any discrepancies are caught early and corrected. This process not only enhances part consistency but also helps identify potential production issues.

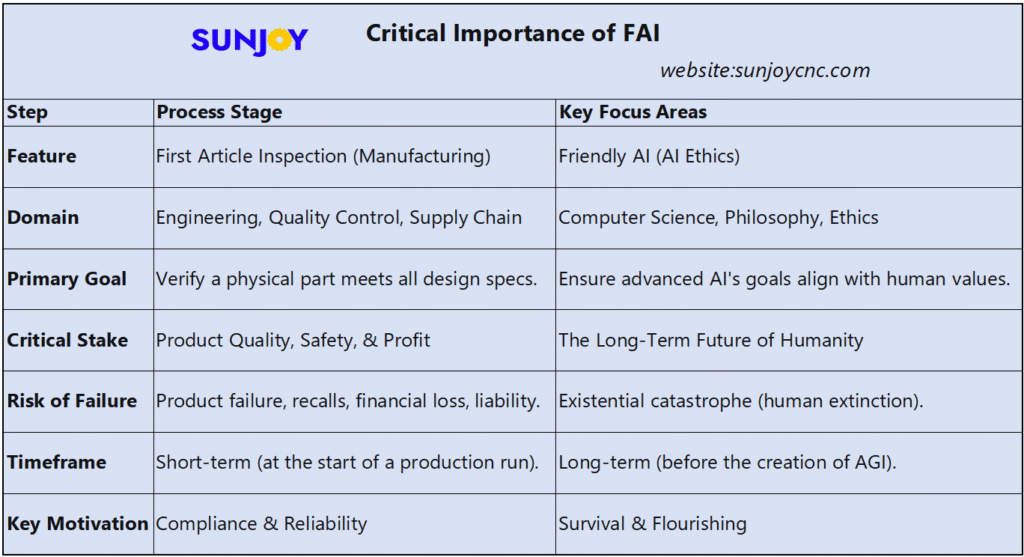

Why is FAI critical in manufacturing?

FAI isn't optional; it's essential to maintaining the integrity and consistency of manufactured parts.

FAI is critical because it identifies defects early, minimizes waste, and ensures that production stays aligned with design intents. This reduces the risk of costly rework and enhances production efficiency.

Breaking it down further, FAI acts as the first defense against defects that might compromise quality. By catching and correcting errors early, manufacturers can prevent small issues from escalating into larger problems. This proactive approach not only benefits the bottom line but also builds trust with clients, who are assured that parts meet their specifications from the start.

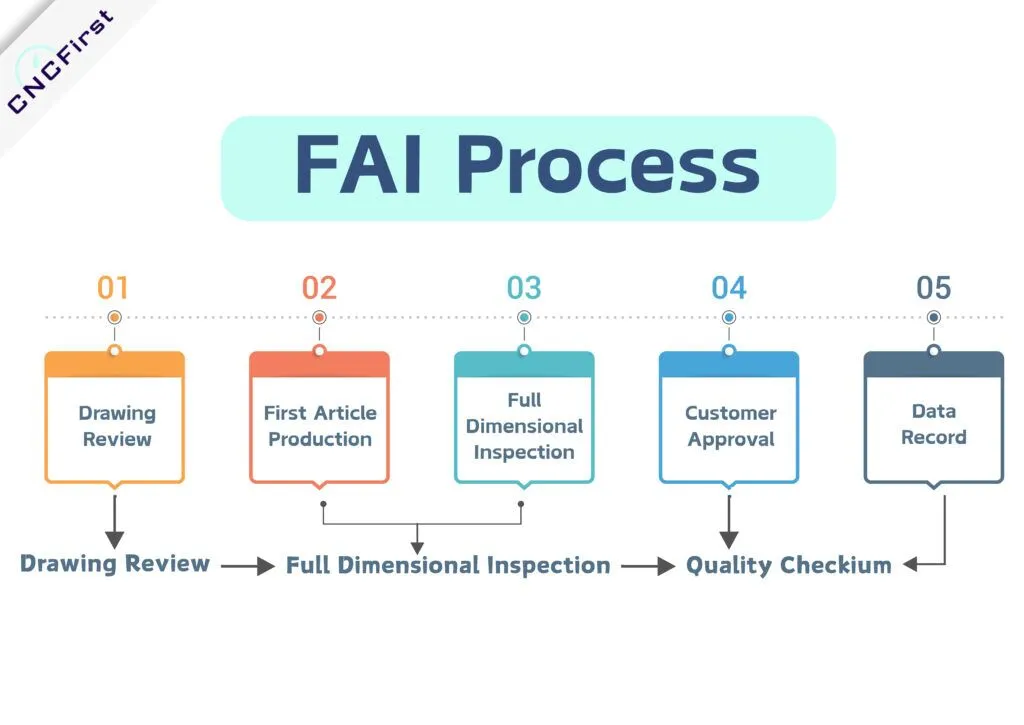

What are the steps involved in FAI?

A clear understanding of FAI steps can streamline your approach and ensure each part meets quality expectations.

The FAI process includes planning, comparing part dimensions and properties with specifications, documenting findings, and resolving discrepancies before proceeding with mass production.

Looking closer, the initial planning phase involves understanding the part design and identifying key features to be inspected. Subsequent steps involve measuring these features using precision tools, analyzing the results against specifications, and documenting everything meticulously. Any identified issues are addressed to prevent recurrence. This structured approach ensures FAI serves as more than just quality insurance—it becomes an integral part of the manufacturing strategy.

Conclusion

First Article Inspection (FAI) lays down the foundation for quality and consistency, bridging design and production with precision.