Lighting design can seem complex. Whether it's the elegance of chandeliers or the functionality of desk lamps, CNC machining is revolutionizing production processes by adding precision and speed.

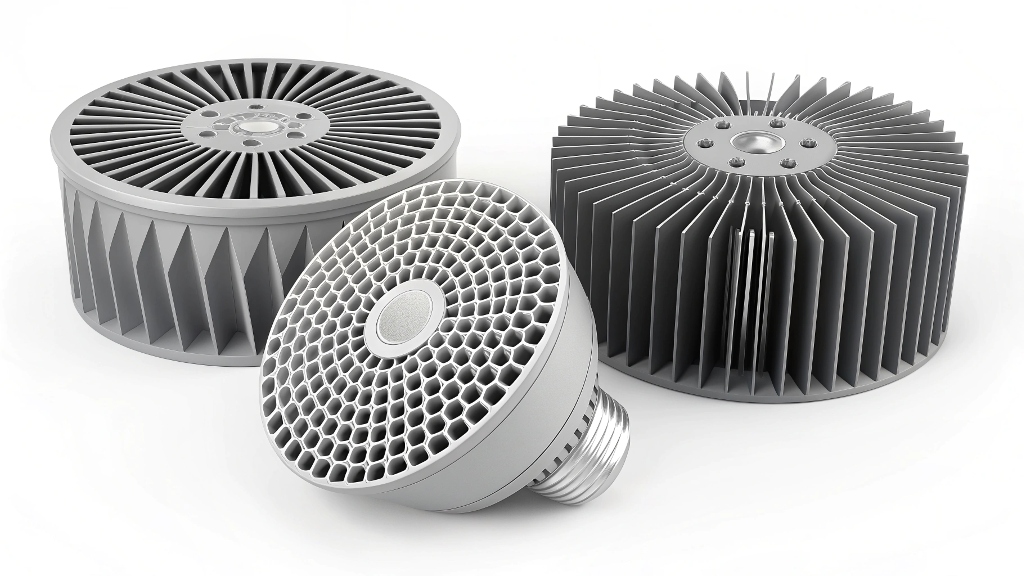

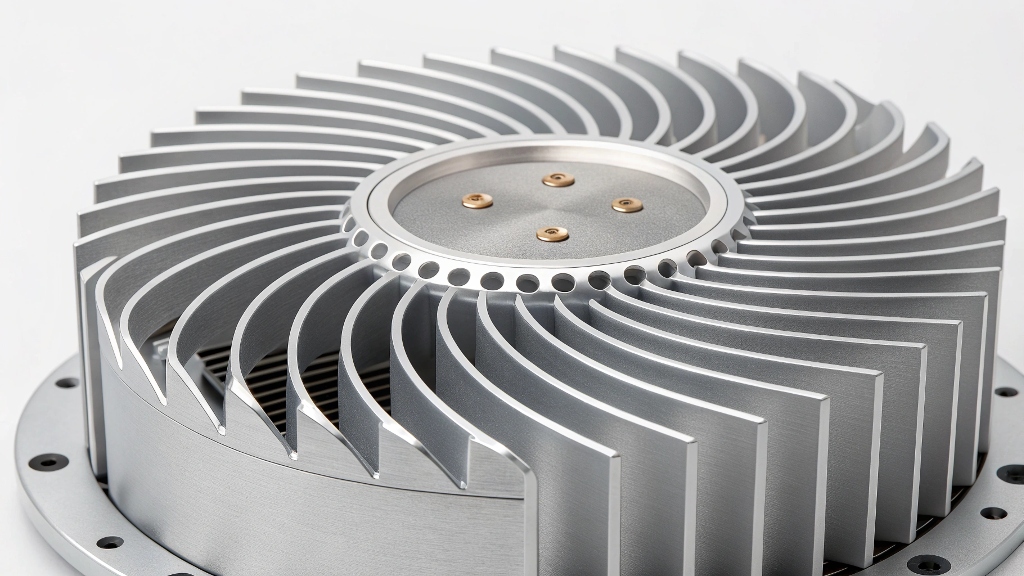

CNC is crucial in lighting production due to its precision and flexibility. It allows manufacturers to create intricate designs with consistent quality, from ornate chandeliers to simple desk lamps.

The use of CNC machining streamlines production. It ensures that each piece is crafted to perfection, reducing waste and increasing efficiency.

What Makes CNC Ideal for Crafting Chandeliers?

Capturing the beauty in a chandelier’s design can be tough. It requires detailed craftsmanship to ensure each piece complements the next. CNC excels in these intricate tasks.

CNC is ideal because it delivers high precision and repeatability. It allows designers to transform complex designs into reality effortlessly and at a lower cost with less material waste.

Chandeliers require the blending of aesthetics with structural integrity. CNC machines are perfect for this task. With the ability to execute detailed cuts, CNC ensures each crystal or metal piece fits seamlessly with the next. Designers can implement innovative ideas without the fear of deviation. The flexibility with materials further enhances creative freedom. Metals, acrylics, and new composite materials can be shaped with more precision. Thus, CNC technology not only democratizes chandelier design but also improves its manufacturability. It makes large-scale production more viable, keeping quality and design intact.

Can Desk Lamps Benefit from CNC Machining?

When you think of desk lamps, simplicity and functionality might come to mind. Yet, do they benefit from CNC like chandeliers? Surprisingly, yes.

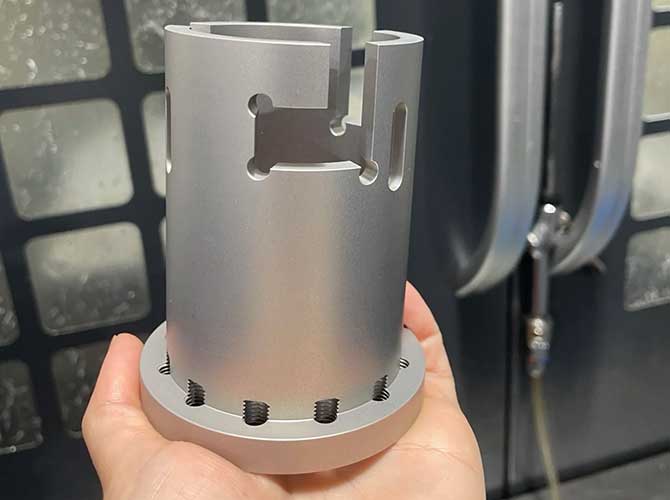

Desk lamps benefit greatly because CNC allows for creating precise parts that fit perfectly. This leads to increased stability and reliability, essential for everyday lighting solutions.

Though simple in appearance, desk lamps require careful design and manufacture. CNC machining can craft components like bases, arms, and heads with precision. This ensures each angle and dimension supports stability. CNC also allows for custom designs in low-volume production, providing uniqueness without increased cost. Moreover, CNC's efficiency reduces development times significantly. These efficiencies cut overall production costs. Customization in colors and materials can happen rapidly, accommodating different customer needs. CNC technology’s role makes desk lamp production not just feasible but also adaptable to market trends.

How Does CNC Contribute to Eco-friendly Lighting Production?

Sustainability in manufacturing is no longer optional. Companies aim to reduce waste and improve processes, and CNC plays a significant role here.

CNC reduces waste by optimizing material use. Advanced programming ensures the least amount of material is used without sacrificing quality, lowering the ecological footprint.

The environmental impact of manufacturing has always been a concern. CNC machining's precision reduces scrap, which lessens waste. Tool paths are programmed for optimal material usage, ensuring that even complex designs are produced efficiently. Additionally, CNC machinery runs on cleaner energy sources and could be paired with eco-friendly materials. These advancements support sustainability goals. Recycling scraps and using residual materials in other processes further aid eco-friendly practices. CNC's ability to replicate designs without error ensures consistency, reducing the need for rework and enhancing resource efficiency.

What Future Innovations Can CNC Bring to Lighting Design?

As CNC technology evolves, so too does the potential for lighting innovation. From smart integrations to avant-garde designs, CNC is reshaping expectations.

The future of CNC in lighting includes smart capabilities, allowing for the integration of sensors and IoT features. It paves the way for personalized and responsive lighting solutions.

CNC machining lays the groundwork for integrating advanced tech into lighting solutions. Imagine lamps that adapt to room ambiance through sensors, or chandeliers intertwined with smart home systems. CNC's precision ensures these complex integrations work seamlessly. It allows for prototyping of new designs rapidly, encouraging innovation without large financial overhauls. Additionally, lightweight materials can be developed through CNC techniques, offering eco-conscious consumers cutting-edge designs. The flexibility and adaptability of CNC will likely propel forward-thinking design concepts into tangible products, revolutionizing how we perceive and interact with light fixtures.

Conclusion

CNC machining not only transforms how lighting products are made but allows for innovative designs, sustainability, and future integration with smart technologies. From chandeliers to desk lamps, CNC's influence is undeniable.