Rust and corrosion can wreak havoc on marine and outdoor lighting setups, leading to costly repairs and replacements.

The use of corrosion-resistant CNC components can significantly extend the life of lighting systems by withstanding harsh environmental conditions. These components are crafted from materials designed to combat moisture and salt exposure.

Choosing materials and designing for corrosion resistance ensures durability and better performance. Let's explore how.

Why Choose Corrosion-Resistant Materials?

Corrosion can severely damage your lighting equipment, quickly turning it from a well-functioning system into a costly liability.

Corrosion-resistant materials such as stainless steel and marine-grade aluminum can withstand environmental stressors like saltwater, significantly enhancing the durability of components used in marine and outdoor settings.

Understanding which materials to choose and why can simplify the decision-making process:

-

Stainless Steel: Known for its strength and anti-corrosion properties. Ideal for harsh, salty environments.

-

Marine-Grade Aluminum: Lightweight and resistant to rust and corrosion. Perfect for outdoor applications.

-

Titanium: Highly durable and corrosion-resistant, yet more expensive. Used when longevity outweighs material costs.

Partnering with knowledgeable manufacturers can also ensure optimal material selection to meet specific needs, further enhancing efficiency and cost-effectiveness.How Does CNC Machining Enhance Corrosion Resistance?

Manufacturing errors can introduce vulnerabilities, leading to premature corrosion and failure of lighting systems.

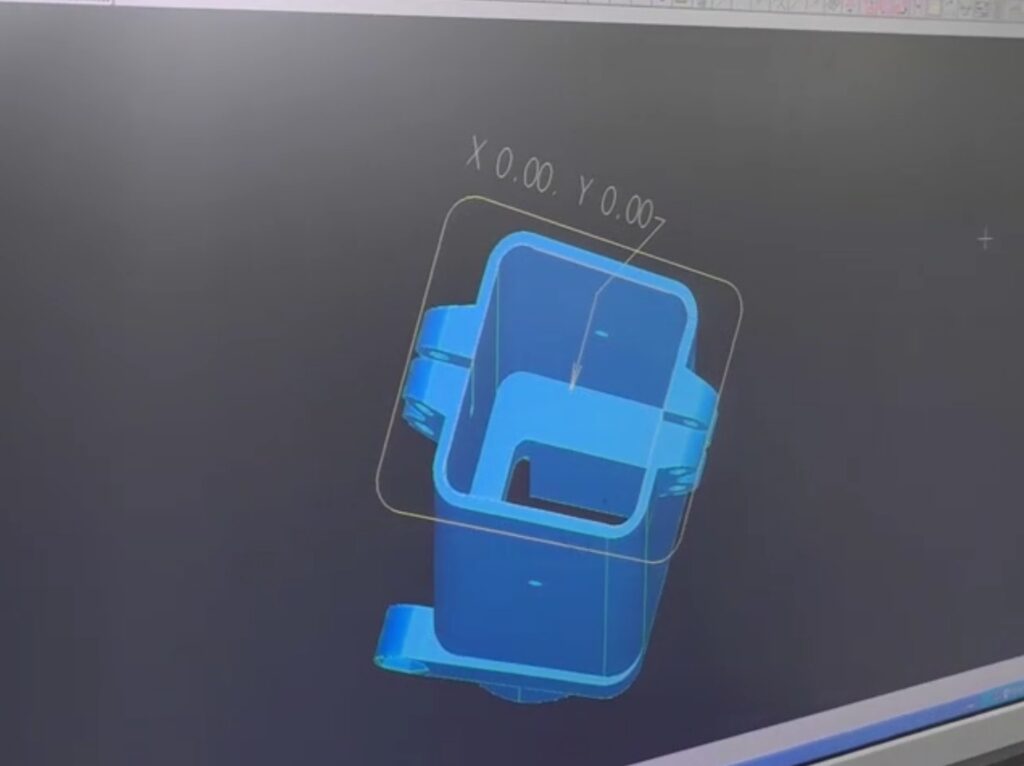

CNC machining ensures precision and uniformity in manufacturing, which is intrinsic to creating tight seals and minimizing surface imperfections that lead to corrosion.

Here’s how CNC machining influences material resilience:

-

Precision Cutting: Avoids unnecessary gaps that allow moisture ingress.

-

Uniform Surfaces: Minimizes micro crevices where corrosion can initiate.

-

Consistent Finishes: Ensures all components meet the desired specifications, reducing vulnerability to corrosion.

Selecting a CNC partner who understands your application and challenges will further enhance component life expectancy and performance.What Are the Key Design Considerations for Outdoor Lighting?

Design flaws can mean the difference between long-lasting installations and frequent maintenance headaches.

Effective design incorporates sealing methods, optimal material choices, and functional ergonomic considerations to combat the environmental challenges of marine and outdoor environments.

Key design elements to focus on include:

-

Sealing Techniques: Use O-rings and gaskets to keep moisture out.

-

Durable Coatings: Apply protective coatings for added moisture resistance.

-

Ergonomic Configuration: Consider aesthetic appeal without compromising protection.

By aligning with experienced design professionals, you can optimize performance and reduce maintenance costs, ensuring reliability even in challenging conditions.How Do Maintenance Practices Affect Longevity?

Neglecting maintenance can set back even the most robust systems, leading to inefficient operation and premature failure.

Regular inspections and cleaning paired with correct maintenance protocols are crucial for preventing buildup and spotting early signs of corrosion in lighting systems.

Here are some steps to integrate into your maintenance routine:

-

Routine Inspection: Identify and address minor issues before they escalate.

-

Scheduled Cleaning: Remove salt and debris regularly to maintain aesthetics and functionality.

-

Use of Appropriate Tools: Ensure the right tools are used to avoid adding wear to components.

Incorporating these practices into a regular schedule can substantially increase system lifespan, reduce downtime, and save costs over time. Thus, coordination with trained maintenance teams becomes equally important.Conclusion

Corrosion-resistant CNC components significantly enhance the longevity and functionality of marine and outdoor lighting. By choosing the right materials, leveraging precise machining, and incorporating robust design and maintenance practices, systems can withstand harsh conditions successfully.