Innovative lighting can change any room, but precision and quality are key. That's where CNC machining comes in, offering unparalleled benefits.

CNC machining enhances indoor lighting by providing precision, durability, and consistency. It meets high standards for appearance and performance, ensuring long-lasting quality.

Customers demand high-quality lighting products, and meeting these expectations requires reliable manufacturing processes. Let's explore how CNC machining fulfills these needs.

What Specific Indoor Lighting Are Ideal for CNC Machining and Why?

Interior lighting choices shape our environment, with CNC machining offering unique benefits for certain designs.

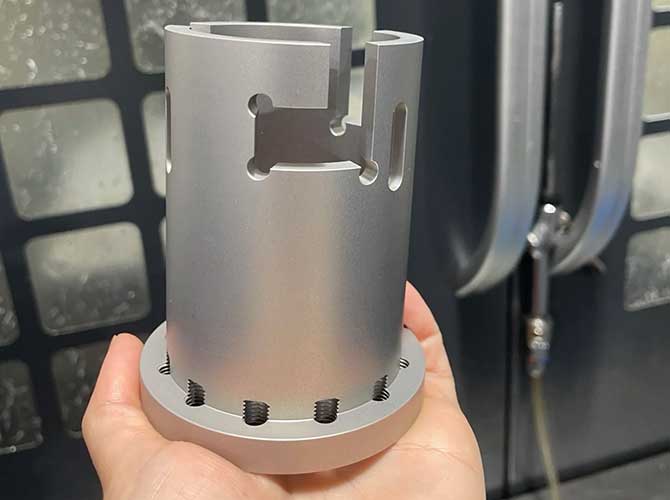

Custom lamp housings, brackets, and heat sinks benefit from CNC machining because it allows precise shaping and accommodates complex designs.

For example, a custom-designed lamp housing requires meticulous design to ensure it fits perfectly within existing spaces. CNC machining offers exact cutting precision, which results in visually appealing and functional parts. Brackets hold parts together securely and should be strong and durable. Heat sinks need to manage temperature effectively and be custom-shaped for optimal performance. CNC machining's precision ensures these components function flawlessly, enhancing both performance and aesthetics.

How Does CNC Machining Enhance the Accuracy and Durability of Indoor Lighting?

Lighting fixtures must be reliable, which depends on accurate and durable components.

CNC machining enhances accuracy and durability by using precise cutting tools and techniques, preventing defects and wear.

Precision is critical when crafting components like reflector cups or intricate lighting frames. CNC machining ensures each part maintains exact dimensions, reducing the risk of defects. This manufacturing accuracy extends the life of the components, ensuring consistent performance over time. Additionally, the durability of machined parts is heightened due to the high-quality materials and precise assembly. This precision not only keeps products functional longer but also maintains their aesthetic appeal.

From Prototype to Production: How Does CNC Machining Accelerate Indoor Lighting Development?

Designing new lighting can be slow, but CNC machining accelerates the timeline from concept to product.

CNC machining speeds up development by allowing rapid prototyping and scalable production, making it easier to transition from design to final product.

When designing a new lighting fixture, speed is critical. CNC machining provides quick turnaround times for prototypes, enabling immediate testing and iteration. This ability to rapidly produce and modify designs cuts development time significantly. Furthermore, once a design is finalized, CNC machining facilitates easy scaling to full production levels without losing quality or precision. This flexibility lets manufacturers adapt swiftly to market demands, delivering high-quality products when needed.

Except CNC Machining Service, What Else Service Can Sunjoy Offer for Indoor Lighting Production?

Choosing the right partner for lighting production means considering a variety of services.

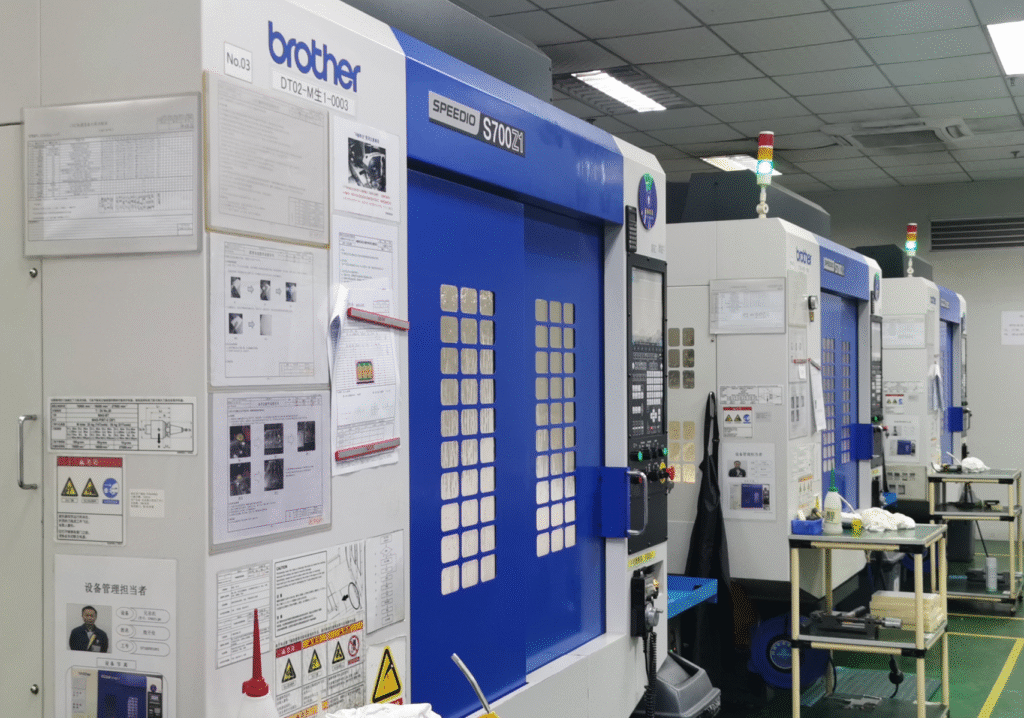

Besides CNC machining, Sunjoy also provides CNC turning and sheet metal stamping services, engineering support, design consultation, and post-production services to ensure comprehensive production needs are met.

Sunjoy offers more than just machining; they collaborate with clients through the entire production process. Engineering support helps tailor designs to manufacturing capabilities, optimizing functionality and cost. Design consultation ensures aesthetic and performance goals are met from the start. Additionally, Sunjoy provides post-production services like surface treatment, assembly, and quality assurance, delivering complete solutions that save time and resources. Teamwork and communication throughout these stages create superior indoor lighting products tailored to specific needs.

Conclusion

CNC machining fuels innovation in indoor lighting through precision, durability, and efficiency. Sunjoy enhances every step, offering a full suite of services for lighting excellence.