Outdoor lighting requires precision and durability. Many users demand high performance and aesthetic appeal. How can CNC machining meet these needs effectively?

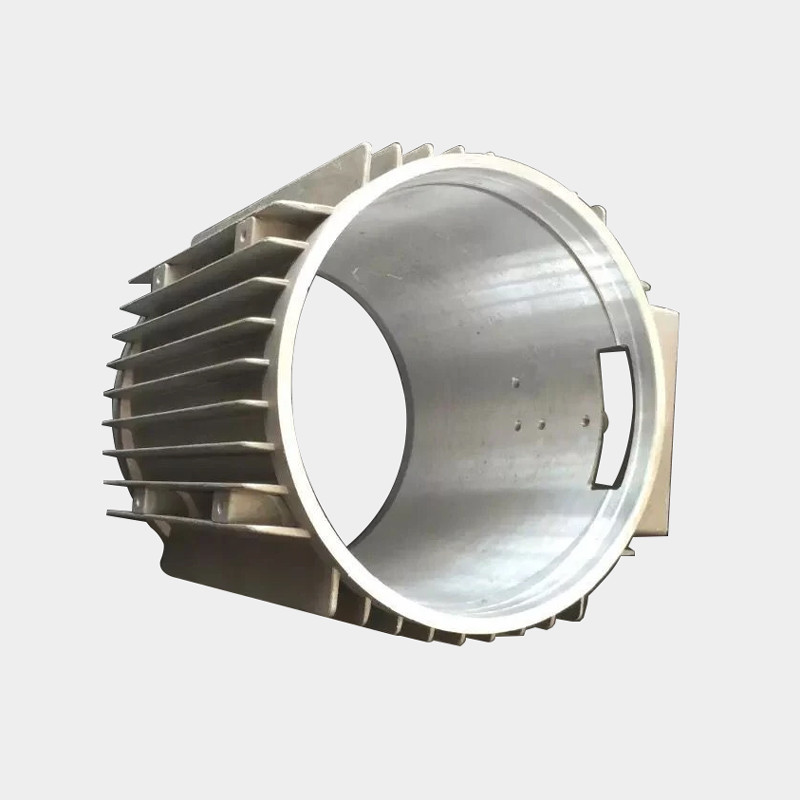

CNC machining benefits outdoor lighting parts by offering precision manufacturing, enhancing durability, and improving aesthetic appeal. CNC processes allow detailed customization, crucial for outdoor lighting that must withstand environmental stresses and maintain a polished look.

Outdoor lighting demands weather resistance and flawless design to function optimally in harsh conditions. CNC machining's precision output ensures high-quality components that meet these requirements.

What Specific Outdoor Lighting Are Ideal for CNC Machining and Why?

Outdoor environments can be harsh. Lighting needs both design excellence and functional reliability. How can CNC machining deliver perfection?

Specific outdoor lighting that benefits from CNC machining includes streetlights, garden lights, and architectural lighting. CNC machining allows precise manufacturing of complex metal components necessary for durability and aesthetic excellence.

Streetlights and garden lights face various environmental stresses, demanding sturdy construction and careful design. CNC machining enables the creation of intricate designs with exact specifications. It allows using high-quality metals optimized for durability and visual appeal. CNC machining also supports rapid prototyping, translating designs into tangible products faster—ensuring manufacturers meet tight deadlines without sacrificing quality. These capabilities make CNC machining a vital process in ensuring outdoor lighting not only survives but shines in tough conditions.

How Does CNC Machining Enhance the Accuracy and Durability of Outdoor Lighting in Extreme Conditions?

Extreme conditions test the mettle of outdoor lighting components. Accurate construction and lasting durability are essential. Can CNC machining rise to the challenge?

CNC machining guarantees precise manufacturing, which enhances the accuracy and durability of outdoor lighting in extreme conditions. It facilitates robust construction using high-quality metal—vital for long-term performance.

When outdoor lighting faces extreme weather, precision and strength are critical. CNC machining excels in creating parts with tight tolerance levels, meaning parts fit together perfectly without unnecessary gaps or weak points. This contributes to the longevity and superior performance of lighting installations. CNC machining’s capability to produce uniform and reliable parts reduces wear and tear, extending the lifespan and effectiveness of the lighting systems. Additionally, the ability to use varied materials makes CNC machining versatile, supporting adaptation to specific environmental needs—creating lights resistant to corrosion, impact, and temperature fluctuations.

From Prototype to Production: How Does CNC Machining Accelerate Outdoor Lighting Development?

Designing outdoor lighting involves refining ideas swiftly to hit market deadlines. How does CNC machining reduce developmental hurdles?

CNC machining accelerates the development of outdoor lighting by facilitating rapid prototyping and streamlined production processes, ensuring designs quickly transition from concept to marketplace-ready products.

Innovation in outdoor lighting requires timely execution. CNC machining supports quick changes and refinements. The process allows designers to rapidly create prototypes for testing and feedback, reducing the project’s time frame. Accurate replication of designs through CNC machining streamlines production, making scaling up efficient once prototypes receive approval. This ability to move quickly from design concepts to final products reduces developmental costs and shortens lead times. The precision of CNC machining ensures that initial design intricacies are retained from prototype through to full-scale production, guaranteeing consistent product quality and reliability.

CNC vs. Other Manufacturing Methods: Why is it the Superior Choice for Outdoor Lighting Parts?

Manufacturing methods differ in efficacy and quality. How does CNC machining surpass alternatives for outdoor lighting components?

CNC machining is superior for outdoor lighting parts due to its unmatched precision, customization capabilities, and efficiency. It offers benefits traditional methods cannot match.

Comparing CNC machining with other manufacturing techniques reveals clear advantages. Traditional methods like stamping or casting often require extensive post-processing to achieve desired finishes, adding time and cost. CNC machining delivers precise cuts with minimal need for additional work. The flexibility of CNC machining allows intricate designs and complex geometries impossible with other methods—meeting aesthetic and functional requirements seamlessly. Its automated nature reduces human error, ensuring consistent high-quality parts. Additionally, CNC machining offers scalability and adaptability without compromising quality, making it essential in the demanding arena of outdoor lighting manufacturing.

Conclusion

CNC machining revolutionizes outdoor lighting through precise, durable, and aesthetically superior components, meeting high demands with efficiency.