Projector manufacturers constantly face the challenge of balancing high-quality output with efficient production. Issues like component precision and durability demand solutions that can deliver consistent results.

CNC machining enhances projector component quality by offering precise and durable parts through automated processes, minimizing human error, and increasing production efficiency, resulting in superior projectors.

Behind every seamless projection lies the need for components that perform exceptionally. Delving deeper, we’ll explore how CNC machining stands out for projector manufacturing.

What Specific Projector Components Are Ideal for CNC Machining and Why?

Producing high-quality projectors demands meticulous attention to detail where precision is key. Identifying the ideal components for CNC machining is crucial.

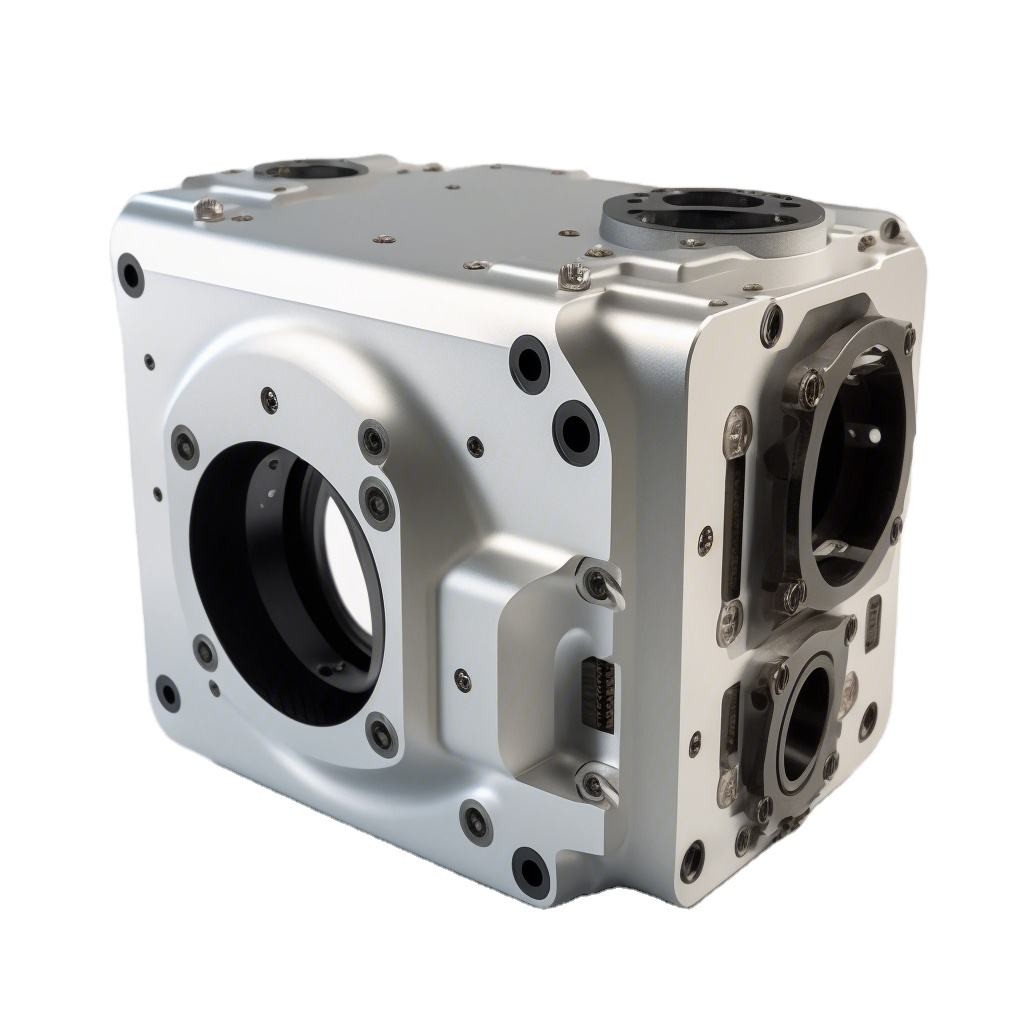

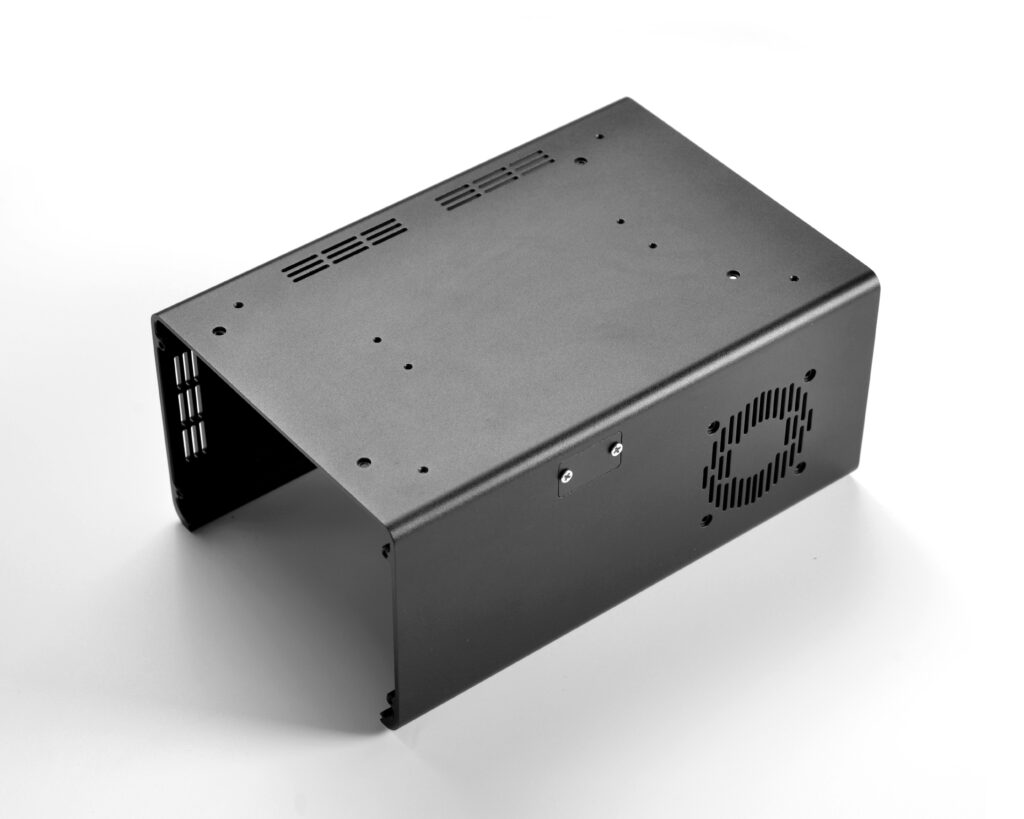

Components like the projector casing, lens mounts, and internal housing are ideal for CNC machining due to their need for precision, strength, and flawless finishes.

Projectors require components that are smooth, precise, and durable. CNC machining ensures that these components meet exact specifications with exceptional quality. The lens mounts, for example, must hold lenses with precision to maintain image clarity. The casings need seamless finishes to prevent scratches, central to aesthetic appeal. CNC processes allow for consistent production that maintains these high standards, essential to today’s market demands.

Anodizing and sandblasting are used very commonly. They look excellent and can protect products from scratching.

How Does CNC Machining Enhance the Accuracy and Durability of Projector?

Accuracy and durability are non-negotiable in projector manufacturing. Meeting these demands requires advanced production methods.

CNC machining enhances projector accuracy and durability by using computer-controlled precision to produce parts that reduce wear, ensuring longevity and reliability.

The importance of accuracy cannot be overstated in modern projectors. Each component must fit perfectly to avoid misalignment, which can degrade image quality. CNC machining achieves this by offering unmatched precision. Additionally, durable components reduce maintenance and increase the lifecycle of projectors. Using high-quality materials and precise manufacturing processes, CNC machining ensures each part meets strict quality standards, resulting in robust and dependable projectors.

What Can Sunjoy Do For Projector?

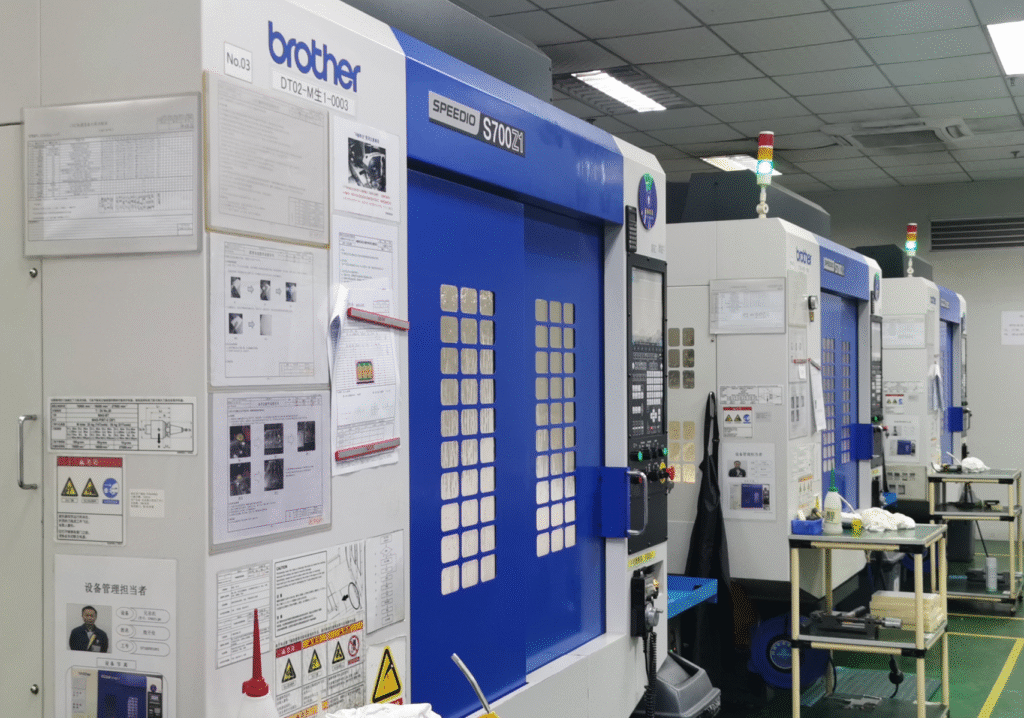

Established by an engineering expert, Sunjoy has consistently set a standard for quality in projector manufacturing, backed by experience and innovation.

Sunjoy improves projector production by providing expertly machined components, adhering to strict quality standards, and offering simple assembly solutions to clients.

Sunjoy’s expertise brings significant value to projector production. By leveraging advanced CNC machining practices, we produce components that meet rigorous aesthetic and functional demands. Our experience with projector clients ensures that no scratch mars the elegant surface of any component. Besides, Sunjoy provides assembly solutions that streamline manufacturing, delivering not only parts but comprehensive solutions that uphold client specifications and enhance overall production efficiency.

CNC vs. Other Manufacturing Methods: Why is it the Superior Choice for Projector Parts?

Choosing the right manufacturing method is crucial for producing superior projector components. Understanding what sets CNC apart is essential.

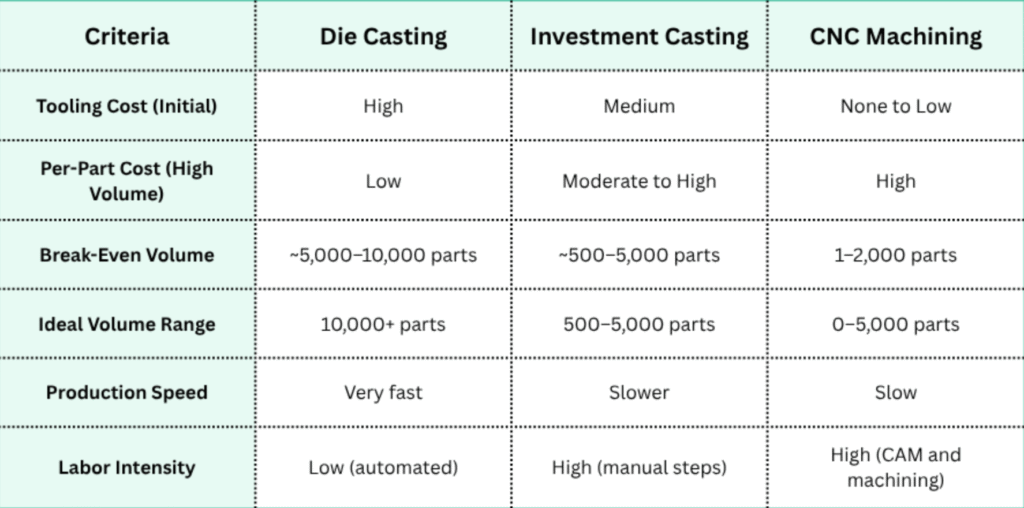

CNC is superior for projector parts production due to its precision, consistency, and efficient use of materials, outperforming other methods like injection molding or casting.

Traditional methods like injection molding and casting lack the precision and flexibility of CNC machining. With CNC, every piece can be crafted to exact specifications, resulting in fewer errors and material wastage. CNC provides the adaptability needed to create complex parts tailored to unique designs, enhancing the overall performance and lifespan of projectors. Its ability to efficiently produce small or large batches without compromising quality sets CNC apart, making it the preferred choice for forward-thinking manufacturers.

Conclusion

CNC machining significantly enhances projector manufacturing by ensuring precision, durability, and efficiency in production, resulting in high-quality projectors that meet modern market demands.