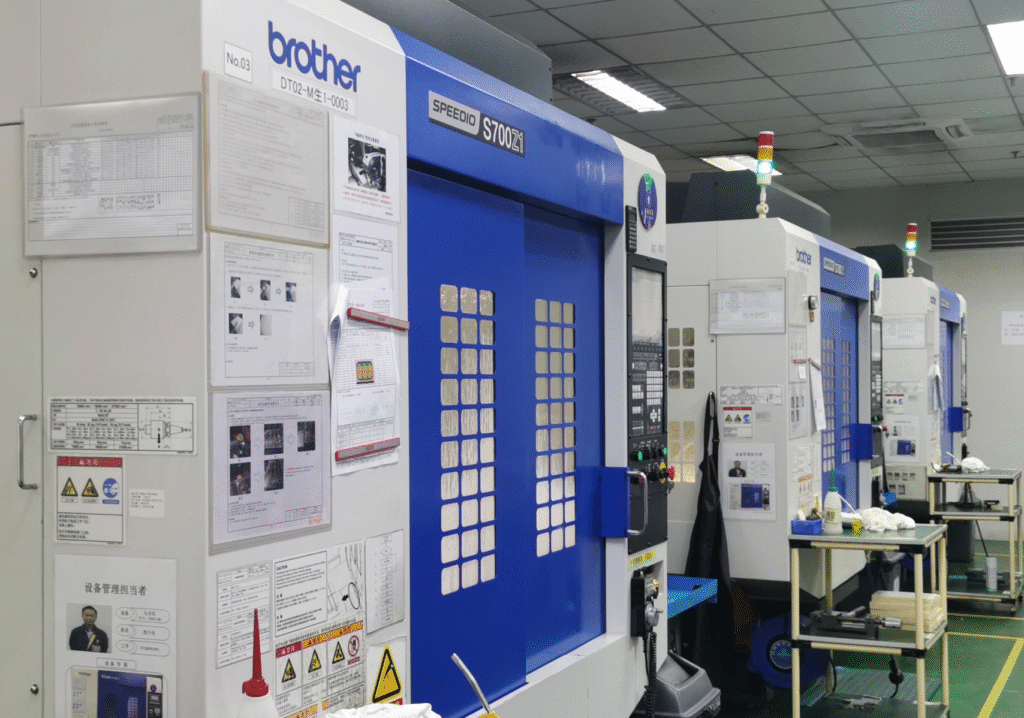

Understanding how CNC machining transforms rangefinder components can revolutionize your approach to design. This powerful technology enhances precision, strength, and efficiency, ensuring top-tier performance.

CNC machining benefits rangefinder parts by offering unparalleled precision, consistent quality, and durability even in extreme conditions. It allows for complex designs, improves material usage, and accelerates prototyping to final production.

CNC machining isn't just about cutting metal. It's about crafting excellence, from intricate internal designs to robust outer shells. Discover how each element benefits.

What Specific Rangefinder Components Are Ideal for CNC Machining and Why?

CNC machining's potential to refine components is transformative for rangefinders. Harnessing precision boosts accuracy and reliability.

Components like housings, brackets, and optical mounts are ideal for CNC machining because they require high precision and durability. CNC ensures tight tolerances and clean finishes, perfect for sensitive devices.

Diving deeper, CNC machining excels in complex geometries, essential for housings that protect sensitive electronics. The robust materials withstand harsh conditions, ensuring longevity. Optical mounts crafted via CNC maintain alignment, critical for accurate readings. With CNC, component consistency becomes achievable, meeting high industry standards and expectations.

How Does CNC Machining Enhance the Accuracy and Durability of Rangefinders in Extreme Conditions?

Enduring extreme conditions demands exceptional craftsmanship. CNC elevates the performance of rangefinders.

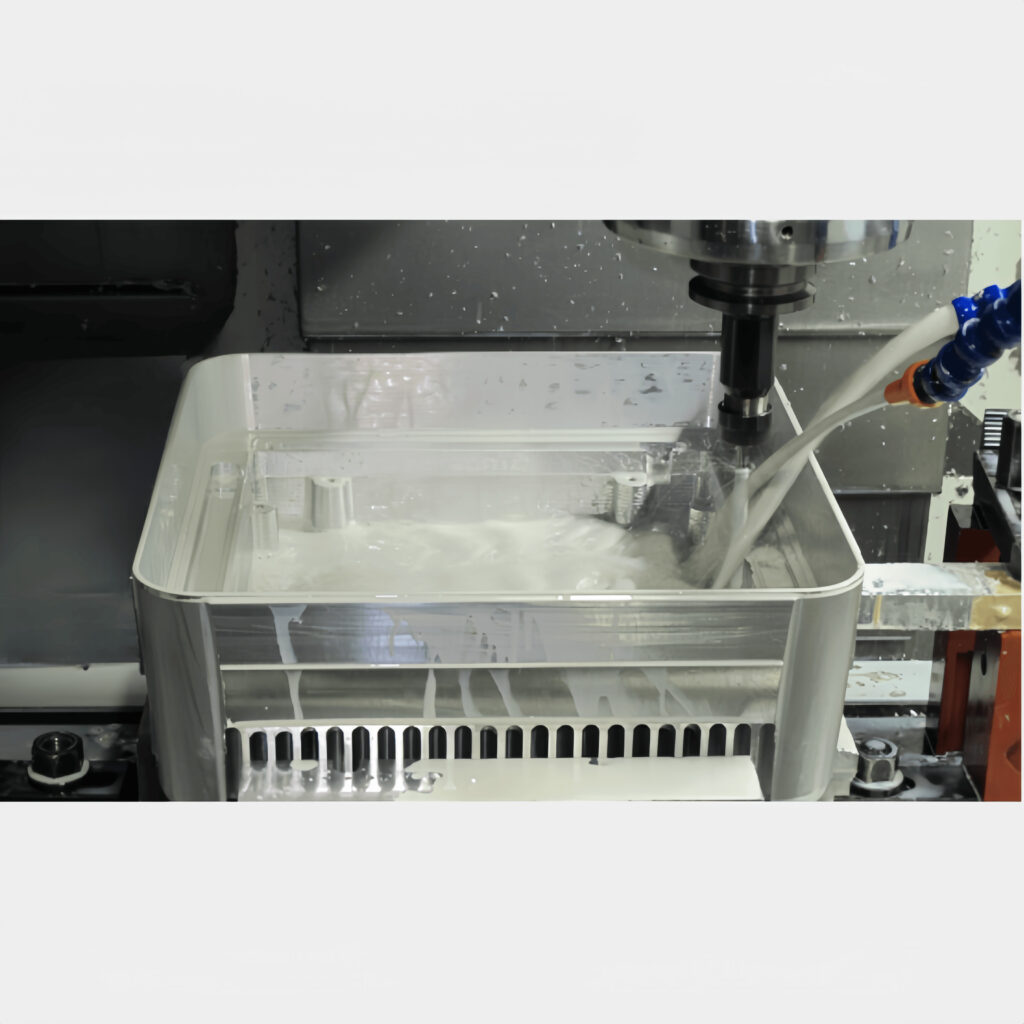

CNC machining enhances accuracy by ensuring perfect alignment of optical parts. Durability is increased through precise tolerance control and use of resilient materials, essential for harsh environments.

Going further, CNC machining uses advanced materials like aluminum and titanium, offering strength without compromising weight. These materials resist corrosion, critical for devices exposed to moisture. By controlling tolerances tightly, CNC machining minimizes wear and tear, extending the lifespan. The precision in machining optical components ensures clear and consistent measurements, vital for accuracy in challenging conditions.

From Prototype to Production: How Does CNC Machining Accelerate Rangefinder Development?

Time is a critical factor in product development. CNC machining streamlines this process for rangefinders.

CNC accelerates development by enabling rapid prototyping, facilitating quick design iterations, and ensuring smooth transition to mass production. This reduces time-to-market significantly.

Delving deeper, CNC machining allows for quick adjustments to prototypes, enabling fast feedback and enhancement. The digital nature of CNC setups allows easy changes to designs without extensive retooling, speeding up iterations. When readiness for production arrives, CNC machines guarantee repeatability and precision, crucial for maintaining quality in large batches. This efficiency helps meet market demands swiftly while maintaining product excellence.

CNC vs. Other Manufacturing Methods: Why is it the Superior Choice for High-End Rangefinder Parts?

Exploring options is crucial for selecting the best method. CNC stands out among manufacturing techniques.

CNC is superior for high-end parts due to its precision, adaptability to complex designs, and ability to produce high-quality finishes. It offers consistent quality and flexibility that other methods can't match.

CNC machining excels in replicating complex components with exact specifications. Unlike other methods, CNC uses computer-guided precision to minimize errors and waste. The flexibility in materials and design possibilities offers unparalleled customization, vital for high-end products. Outputs consistently meet stringent standards, so quality never falters. Other methods may compromise detail or durability, but CNC guarantees integrity in every piece.

Conclusion

CNC machining revolutionizes rangefinder parts with precision, durability, and efficiency, making it the preferred choice for achieving excellence in design and function.