CNC machining costs can feel confusing when you're starting out with budgeting for your projects.

Generally, CNC machining costs range between 30 to 50 per hour, influenced by the complexity of the product and machining requirements.

Pricing CNC machining depends on many factors. But knowing the basic range helps you plan your expenses better. Let’s explore what influences the cost, what metals are cheapest, and how CNC compares with other technologies.

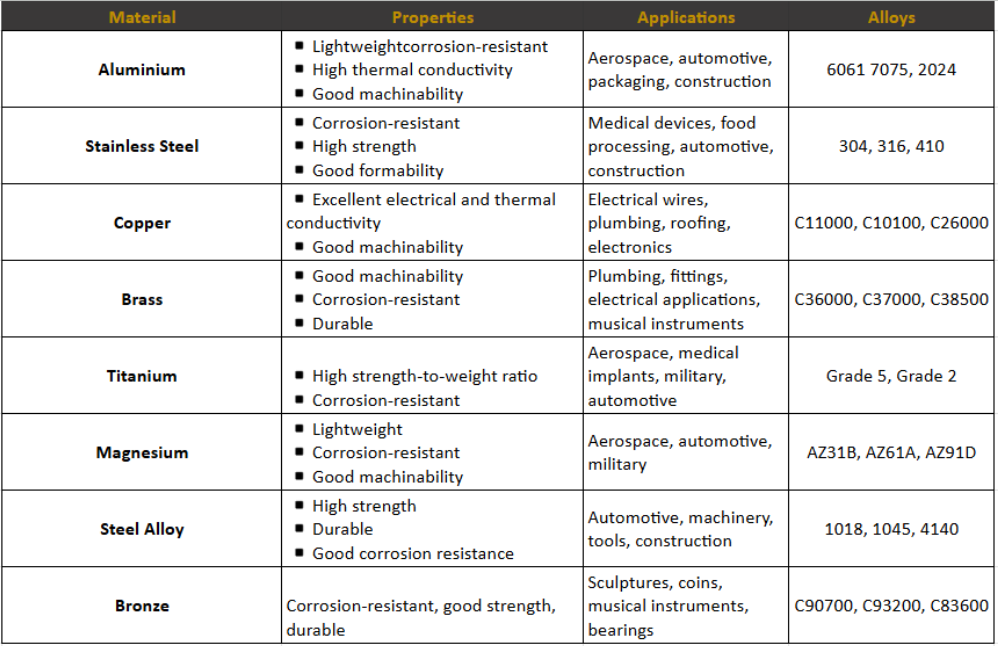

What is the cheapest metal for CNC machine?

Many times, choosing the right metal can cut costs significantly.

Cheapest metals for CNC machining are usually aluminum and mild steel due to their abundance, ease of machining, and lower material costs.

Aluminum and mild steel are popular choices for cost-effective CNC machining. Aluminum is light, resists corrosion, and machines quickly. Mild steel is stronger but usually affordable. Both metals keep machining time short.

| Metal | Cost per kg | Machinability | Durability | Common Uses |

|---|---|---|---|---|

| Aluminum | Low | High | Good | Consumer products, aerospace |

| Mild Steel | Very Low | Medium | Strong | Automotive, machinery |

| Stainless Steel | High | Low | Very Strong | Medical, food industry |

Choosing aluminum or mild steel lowers machining hours and material expenses, helpful especially for prototyping or large batches.

Is CNC in high demand?

Understanding demand helps predict costs and career opportunities.

CNC machining is in high demand, driven by industries like aerospace, automotive, and electronics that need precise metal parts.

Demand for CNC machinists and services continues growing. Industries need precision, speed, and quality in production. Automation and new materials fuel demand, making CNC machining a growing field.

Industrial needs push CNC machine shops to stay updated with technology. CNC also helps companies reduce labor costs and increase production efficiency in competitive markets.

How much electricity does a CNC machine use per hour?

Electricity can be an overlooked operating cost in CNC machining budgets.

On average, CNC machines use between 3 to 10 kWh per hour based on machine size, function, and workload.

Energy use varies widely. Small, simple CNC mills might use 3-5 kWh per hour, while larger, multi-axis machines consume up to 10 kWh or more. Idle machines use less power but still draw some electricity.

| CNC Machine Type | Approximate Power Usage (kWh/hour) | Notes |

|---|---|---|

| Small 3-axis mill | 3 - 5 | Suitable for light work |

| Medium-size CNC lathe | 5 - 7 | More powerful cutting tools |

| Large 5-axis machine | 8 - 10 | Complex parts and heavy work |

Tracking electricity helps estimate total production cost and can guide decisions on machine choice or operating hours to control expenses.

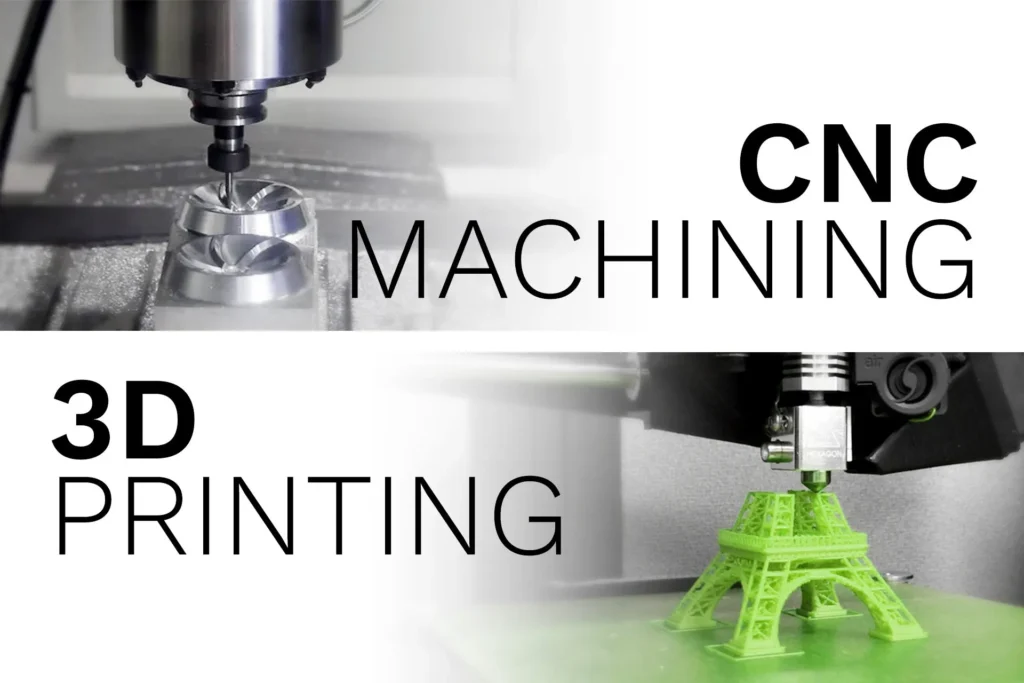

Is CNC machining cheaper than 3D printing?

Choosing between CNC machining and 3D printing depends on the project requirements and volume.

Typically, CNC machining is cheaper for metal parts in larger quantities or prototypes needing strong, precise finishes.

3D printing shines in rapid prototyping and complex shapes without tooling costs but may have higher material and finishing costs. CNC machining provides better surface finish and structural strength at scale.

| Factor | CNC Machining | 3D Printing |

|---|---|---|

| Material options | Wide (metals, plastics) | Limited, mostly plastics and some metals |

| Speed for mass prod. | Faster once setup | Slower, layer by layer build |

| Surface finish | High-quality, smooth | Often requires post-processing |

| Cost per unit | Lower for large runs | Lower for one-offs and complex parts |

For metal hardware products, CNC often offers better durability and cost-efficiency, especially relevant to Jacky’s manufacturing work challenges.

Conclusion

CNC machining usually costs $30 to $50 per hour, with metal choice and product complexity affecting final price.