Struggling with production inefficiencies and high costs in CNC machining? Embracing DFM can turn these problems around by optimizing designs for smoother manufacturing processes.

Design for Manufacturability (DFM) in CNC machining involves creating product designs that simplify manufacturing. It enhances efficiency, reduces costs, and ensures high-quality outputs by considering the production process in the initial design phase.

Understanding DFM is essential to streamline production and minimize errors. Implementing DFM principles early in design saves time and resources while enhancing overall product quality.

What are the key principles of DFM in CNC machining?

Ignoring DFM can lead to costly redesigns and production delays. Applying DFM principles is key to avoiding these issues.

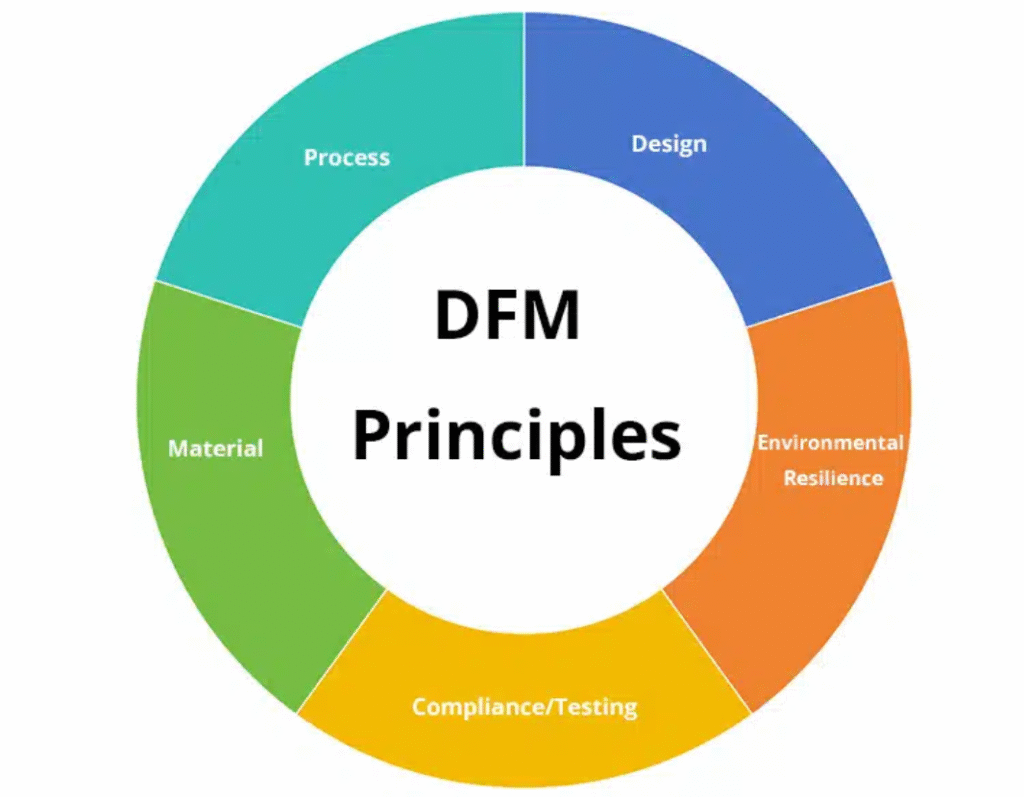

Key principles of DFM in CNC machining include minimizing complex geometries, standardizing components, considering material properties, and designing for efficient machining. These strategies streamline the production process and reduce costs.

DFM revolves around simplifying designs to make manufacturing easier. For instance, reducing intricate part details can decrease machining time. Standardizing components allows for easier assembly and compatibility. Material choice impacts machining behavior and final product performance. By considering these factors early, you reduce the likelihood of errors and rework, resulting in a faster, more reliable manufacturing process.

How can DFM improve efficiency in CNC machining?

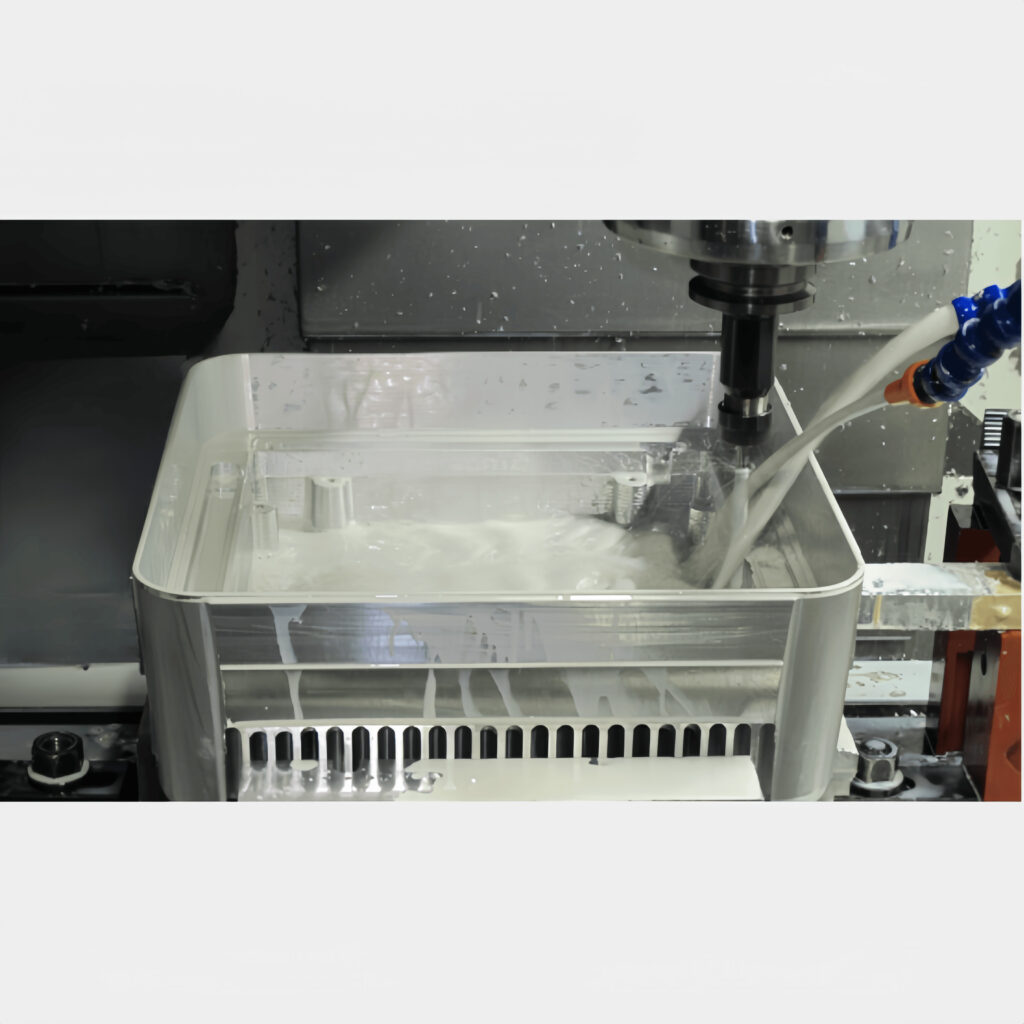

Efficiency is crucial in keeping production costs low. DFM helps optimize processes and enhance productivity in CNC machining.

DFM improves efficiency by reducing machining time and material waste. By designing for streamlined production, DFM eliminates unnecessary complexity, leading to faster and more cost-effective manufacturing.

Think about designing a part with fewer cuts and simpler shapes. This directly impacts machine time and tool wear, resulting in savings. DFM prioritizes creating products that are not only functional but also easy to produce. Reducing the need for complex setups and transitions speeds up the overall manufacturing process. This efficiency translates into cost savings and improved production timelines, meeting market demands effectively.

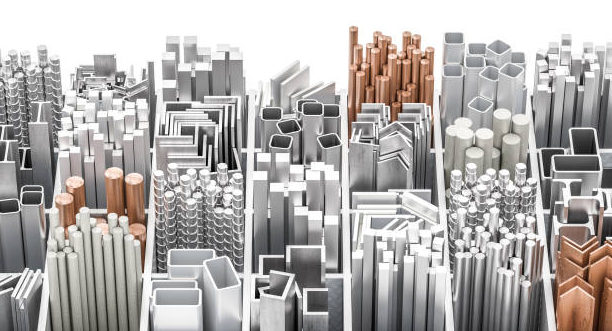

What role does material selection play in DFM?

Choosing the wrong material can derail even the best designs. Material selection is a critical aspect of DFM.

Material selection in DFM plays a vital role by influencing machining ease, cost, and product performance. Selecting materials compatible with CNC processes ensures optimal results and reduces tool wear.

Different materials react differently when machined. Some materials might require special tools or additional time. By understanding these interactions, designers can choose materials that align with the manufacturing process. For example, softer materials might be easier to machine but less durable. Balancing these factors is crucial to achieving quality products without exploding costs. Proper material selection ensures efficient tooling, reduced production times, and longer-lasting parts.

How does DFM affect product quality?

Compromising on design details can harm product quality. DFM ensures designs are robust enough to maintain high standards.

DFM affects product quality by aligning design specifications with manufacturing capabilities. This alignment minimizes defects, ensuring that the final product meets performance and reliability standards.

When a product is designed with manufacturing constraints in mind, it leads to more precise and reliable outcomes. Reducing the complexity of designs means fewer opportunities for errors. Checking tolerances, material interactions, and assembly techniques ensures products deliver consistency and durability. This focus on quality helps build brand reputation and customer satisfaction. Embracing DFM means embedding quality checks from the ground up, leading to superior results.

Conclusion

Design for Manufacturability (DFM) in CNC machining streamlines production, enhances efficiency, and ensures high product quality by optimizing designs for the manufacturing process.