Creating the perfect technical drawing can feel overwhelming. Ensuring clarity and precision can make or break your project.

The perfect technical drawing for CNC suppliers includes precise dimensions, clear annotations, specified tolerances, and material details. This ensures accurate machining and minimizes errors during production.

Feeling lost about how to approach this? Don’t worry; I'll guide you through it step-by-step.

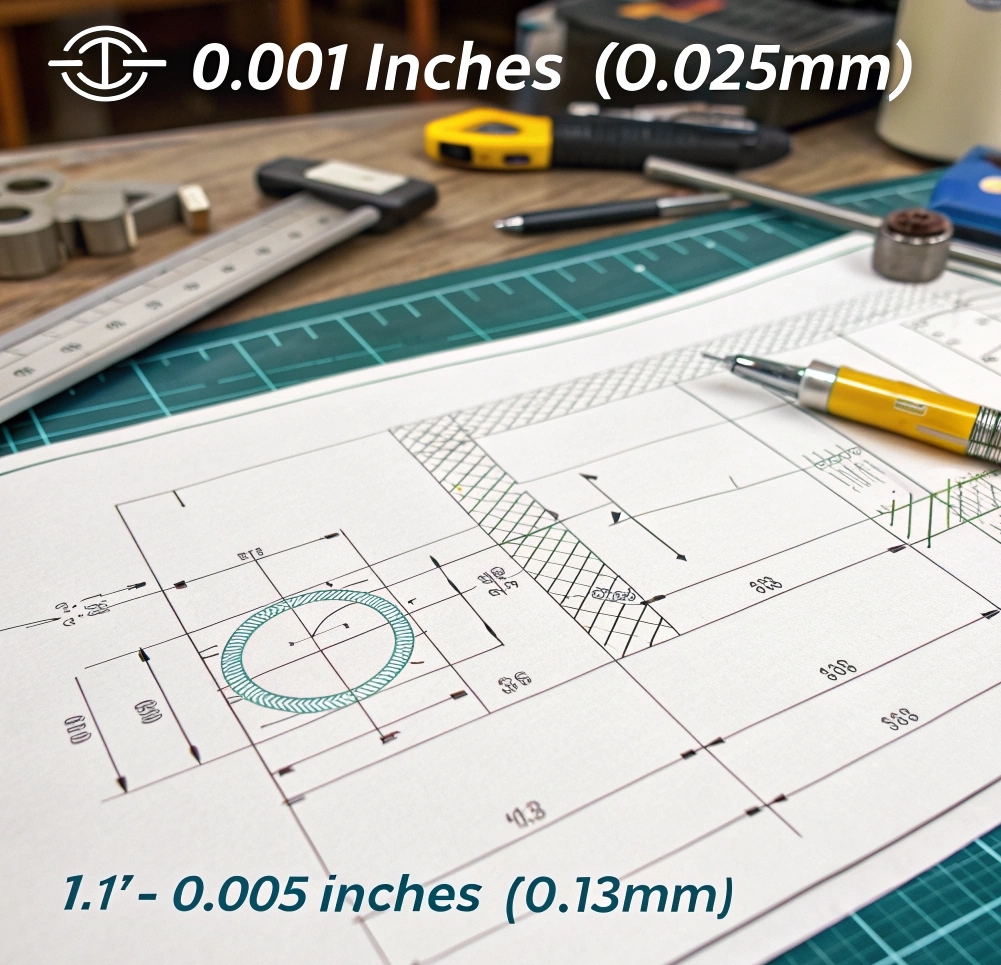

Why Are Accurate Dimensions Critical?

Precision is crucial in technical drawings. Errors can lead to costly mistakes.

Accurate dimensions ensure that the CNC machine cuts the materials to the right size, fitting the final design. It also reduces the chances of production errors.

When I first started in product design, I struggled with dimensions. Over time, I realized that each fraction of a millimeter counts. Use measuring tools effectively. Double-check dimensions. Ensure they match your design specifications exactly.

What Role Do Annotations Play?

Annotations provide clarity and context. They guide the CNC operators.

Ensure that your drawings have clear annotations that explain complex details, specify finishing processes, and address any other important instructions relevant to production.

Reflecting on early projects, I often missed adding necessary notes. This slowed production. Do include instructions on surface finishes, threads, or any specific machining details. Annotations bridge the understanding between designers and operators.

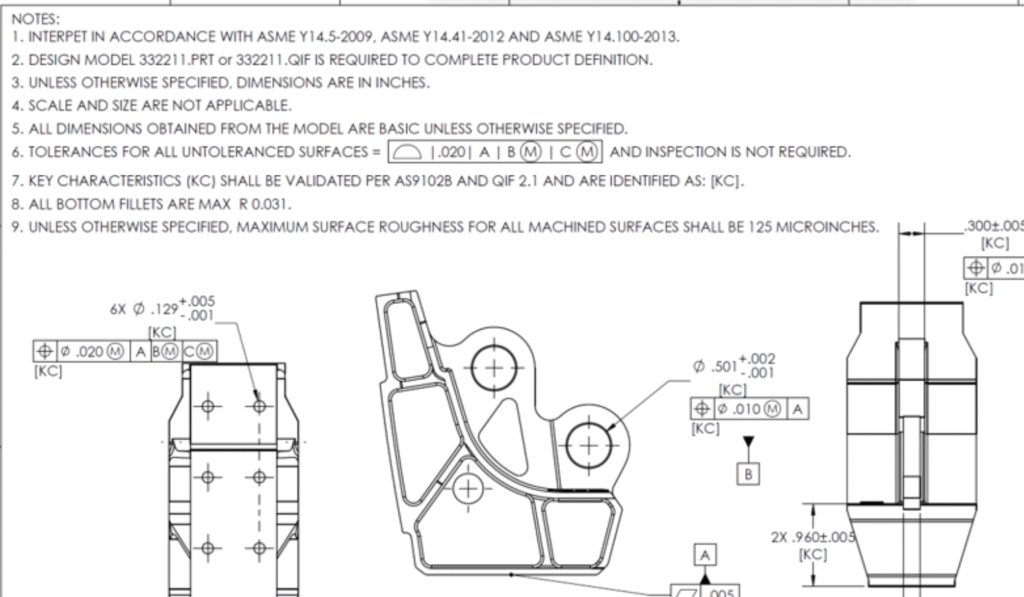

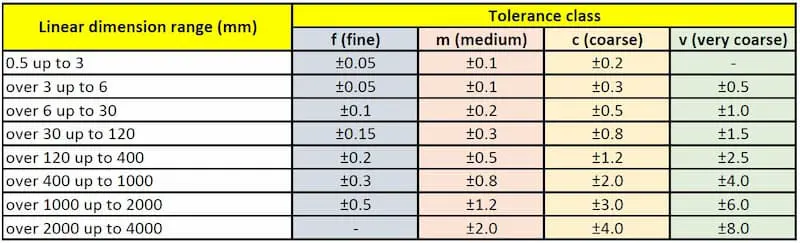

Why Is Tolerance Specification Important?

Without proper tolerances, the end product might not meet your standards.

Tolerances define acceptable variations in dimensions, ensuring that parts fit and function together correctly, even with minor differences during production.

Back in my initial design days, I witnessed a whole batch of parts being unusable due to misunderstood tolerances. To avoid this, define what deviations are permissible. Scour through standards like ISO or DIN if unsure.

How Do Material Details Impact Production?

Material specifics are crucial. They determine the machining process.

Materials influence the machining approach, tool selection, and overall success of your CNC project. Incorrect assumptions can lead to failures in production.

I learned from experience that the right material choice can make a significant difference. Always specify material type, properties, and any required certifications to guide your suppliers efficiently.

How Can You Ensure Clarity in Your Drawings?

Beyond the basic details, clarity prevents miscommunication.

Clear, concise drawings allow CNC suppliers to understand and execute designs effectively, reducing misinterpretations and speeding up the production process.

Juggling between multiple designs in my career, I realized the simple layouts worked best. Use standard symbols, avoid clutter, and employ a clean, consistent style across all drawings.

Conclusion

A perfect technical drawing ensures a seamless production process. Precision, clarity, and detailed annotations are key.