Creating metal prototypes quickly can be a tough challenge. Finding efficient methods to speed up the process without compromising quality can be crucial for success.

Rapid metal prototyping involves using efficient manufacturing techniques to create physical models of a design quickly, enabling testing and refinement before mass production.

Starting with a clear understanding of your design and needs can make the prototyping process more manageable and effective. Let’s explore the essential steps and methodologies that can lead to a successful metal prototype.

What are the 5 steps of rapid prototyping?

Understanding the process of rapid prototyping is essential for timely and cost-effective development. Missing any crucial step might delay your project or compromise its quality.

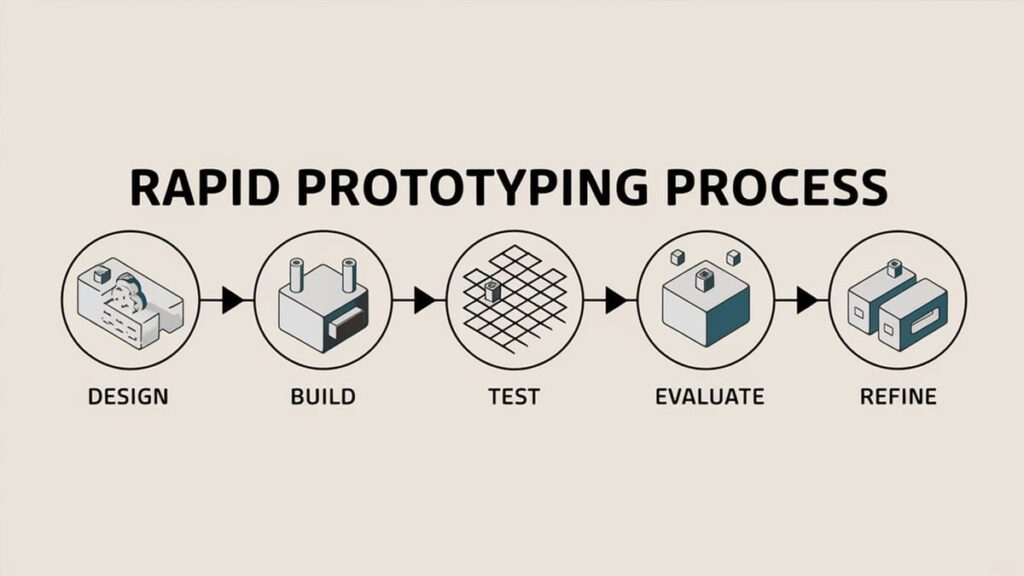

Rapid prototyping typically follows these five steps: design, development, testing, refinement, and finalization. Each step ensures that the prototype meets the intended specifications and functions effectively.

Breaking down further, the design phase starts with a clear concept, often modeled in CAD software. Development involves selecting the right materials and methods to shape the prototype. Testing checks functionality and identifies any issues. Refinement involves making necessary adjustments, and finalization ensures readiness for mass production. This structured approach guarantees a well-rounded prototype suited for its purpose.

What is the methodology of rapid prototyping?

Navigating the world of rapid prototyping requires a proven methodology. With it, you ensure precision and efficiency throughout the production process.

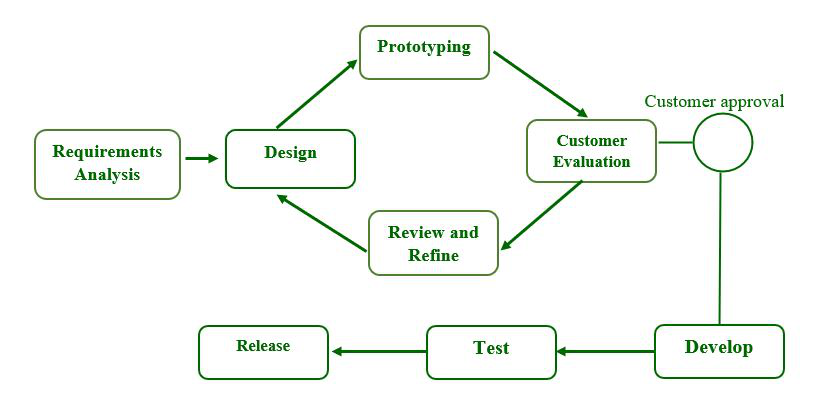

Rapid prototyping methodology focuses on iterative development and feedback loops. This involves repeated cycles of design, production, assessment, and revision to refine the prototype.

Dive deeper into this methodology by considering key elements like continuous user feedback, adaptive changes, and collaboration between designers and engineers. This feedback-driven process aids in identifying flaws early, enabling swift corrections. Adaptive changes allow prototypes to evolve rapidly, balancing innovation with functionality. Collaboration ensures diverse expertise contributes to comprehensive solutions, making the methodology robust for varied projects.

Which manufacturing technique is widely used for rapid prototyping?

Choosing the right manufacturing technique can accelerate rapid prototyping and ensure the creation aligns with your vision. Selecting poorly might hinder your progress.

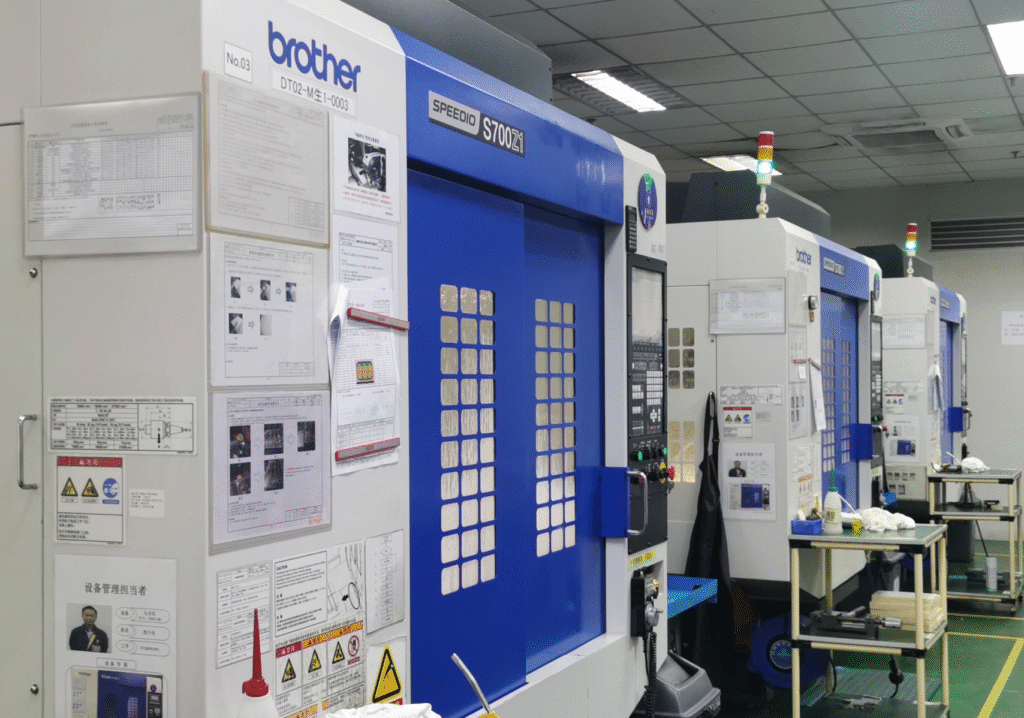

CNC machining is widely used for rapid prototyping due to its precision and efficiency. This computerized technique handles complex designs and various materials effectively.

CNC machining works by utilizing computer-aided controls to craft prototypes with exact specifications. It efficiently handles complex geometries while maintaining tight tolerances. Alongside CNC turning and sheet metal stamping, it allows for versatile production. These methods collectively offer a compelling solution for projects requiring intricate, precise metal prototypes, minimizing errors and wastages while ensuring rapid delivery.

How do I get my prototype manufactured?

Taking your prototype from idea to reality requires careful planning and execution. Any misstep can result in delays or increased costs.

To manufacture a prototype, first create detailed CAD drawings and material specifications. Then, partner with a reliable OEM metal fabrication manufacturer like Sunjoy for quick production.

Begin with clear CAD drawings, detailing every aspect. Choose materials that match your prototype’s function. Collaborate with an OEM manufacturer who’s proficient in CNC machining and metal fabrication. Sending your design to Sunjoy, for instance, enables quick creation with a five-day turnaround. Their expertise in CNC and stamping ensures your prototype’s refinement, adhering to both aesthetic and functional requirements. This approach combines technical precision with effective collaboration, ensuring your prototype meets expectations efficiently.

Conclusion

Rapid metal prototyping relies on efficient processes and collaborative methodologies to transform ideas into functional prototypes quickly and accurately.