CNC machining can look risky, making many wonder if it really is dangerous to work with these powerful machines.

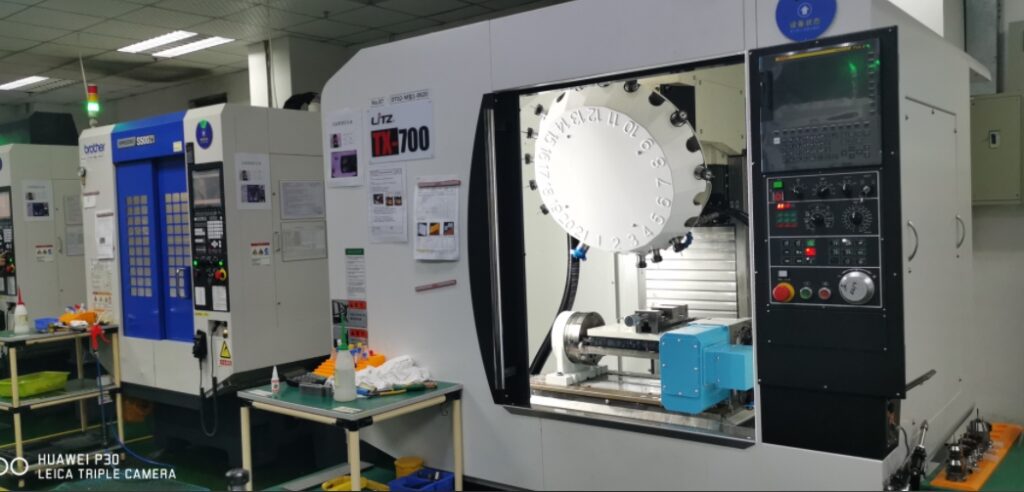

CNC machining is both dangerous and safe. The dangers come from moving parts and high-speed tools, but they are controllable through strict safety rules like never opening the machine door while it runs. Operators only load materials when the machine is off.

CNC machining might seem dangerous at first glance. However, understanding how to control the risks makes the work much safer. Let’s explore the real dangers, the operator’s risks, the ease of operation, and the role math plays in making CNC machining efficient and safe. This way, you will know what to expect and how to protect yourself if you work with these machines.

What Are the Dangers of CNC Machining?

The thought of sharp tools spinning at high speed might raise safety concerns about CNC machining.

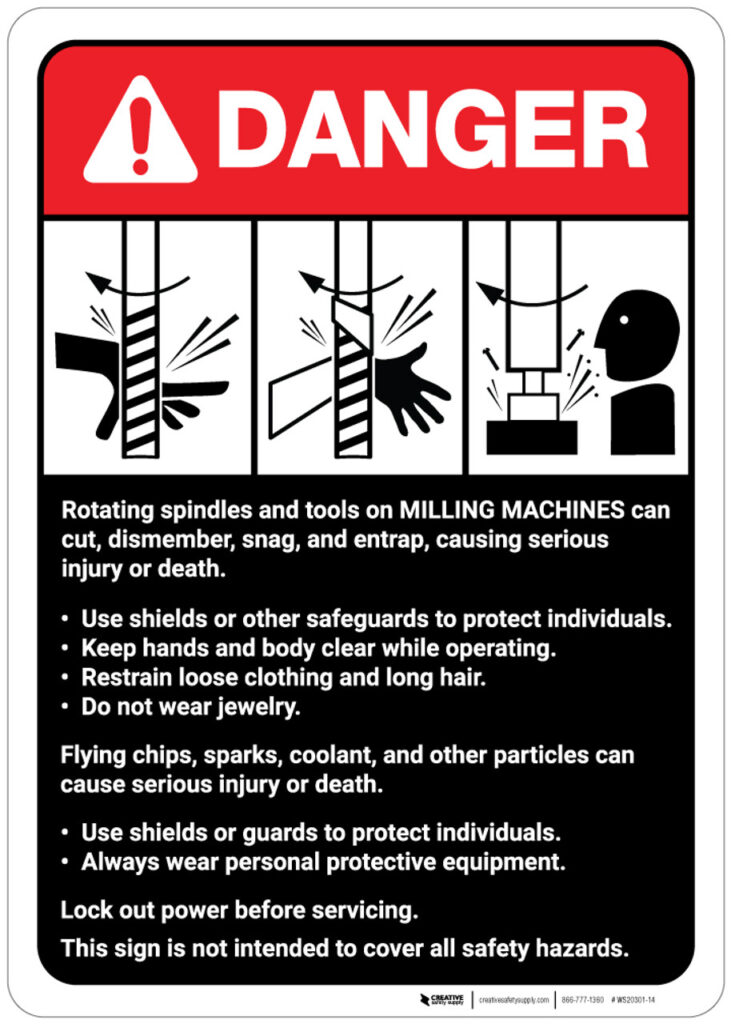

The main dangers in CNC machining come from the fast-moving cutting tools and heavy machinery parts. Injuries usually happen when safety procedures are not followed, especially if the machine door is opened during operation.

Dangers come from mixing moving tools with human presence. Precautions like locking the door and emergency stop buttons reduce risks. Operators must be trained to handle unexpected problems and never interfere while the machine runs. Machines also have shields and barriers that keep cutting parts away from operators. Understanding these dangers helps us respect safety rules for a secure working environment.

Here’s how CNC machines keep you safe and the typical dangers involved:

| Danger Type | Cause | Safety Measure |

|---|---|---|

| Moving cutting tools | High-speed rotation and sharp edges | Machine enclosed, door locked during operation |

| Heavy machine parts | Moving axes and heavy components | Emergency stop, proper training |

| Electrical risks | Power supply and controls | Regular maintenance, safety switching |

| Material handling | Loading and unloading parts | Machine off during loading/unloading |

Each danger is well known, and rules are in place to keep operators safe. Machines are designed with these dangers in mind, which make CNC machining safer than it looks.

Is CNC Operator a Dangerous Job?

You might ask if working as a CNC operator is risky compared to other jobs in manufacturing.

CNC operator jobs are not highly dangerous if safety procedures are followed. The main risk occurs if the operator tries to open the door or touch the machine while it runs. Otherwise, the job is safe with careful work habits.

Good training and discipline lower the risk significantly. Operators always check that machines have stopped before entering or changing materials. The machines have safety switches that stop operation if the door opens. So, the job is more about following rules and being careful than about real danger.

When I first started, I was nervous about the machines. But learning safety and handling the machines carefully made me confident. CNC operators mostly monitor the process and load materials, which does not require being near moving parts. Therefore, while there is inherent danger, it is easy to avoid with good habits.

How Difficult Is It to Operate a CNC Machine?

Some wonder if operating a CNC machine is very hard or requires special skills.

Operating a CNC machine takes training but is not extremely difficult. Operators learn to load programs, set tools, and manage materials. The machine does most of the work automatically once set.

To operate CNC machines, you must understand the controls and safety rules. Programming and setup take practice, but the operators usually don’t control cutting directly by hand. They focus on starting the machine, monitoring it, and changing parts after it stops. That lowers the skill barrier compared to manual machining.

Here is a simple breakdown of operator tasks:

| Task | Description | Skill Level Needed |

|---|---|---|

| Loading program | Upload CNC code to machine | Basic computer understanding |

| Setting up tools | Attach and align cutting tools | Precision and hands-on experience |

| Starting machine | Begin automatic machining process | Following safety checks |

| Monitoring process | Watch machine running and detect errors | Attention to detail |

| Change materials | Remove finished parts safely after stop | Safe handling and timing awareness |

Operating CNC machines combines technical knowledge with safety awareness. It’s easier than it seems with training and experience.

Is There a Lot of Math in CNC Machining?

It’s common to think CNC machining involves complex math, but is that true?

There is some math in CNC machining, mainly for programming and precision measurements. Operators don’t solve math problems daily, but they must understand measurements, geometry, and basic calculations to set up and check machines.

Math is important in design and programming, often handled by CAD/CAM software. Operators use math to verify dimensions and tolerances. Knowing geometry helps with tool paths and angles. So, while you don’t need advanced math skills on the shop floor, a basic math background improves understanding and effectiveness.

For example, an operator might calculate tool offset or confirm part size using simple arithmetic. Programming often requires knowledge of coordinates and angles to create the correct tool path. This teamwork between operators and programmers makes CNC machining precise and efficient.

Conclusion

CNC machining involves dangers but follows strict safety rules making it safe. Operating is manageable with practice, and math knowledge helps but is not overwhelming.