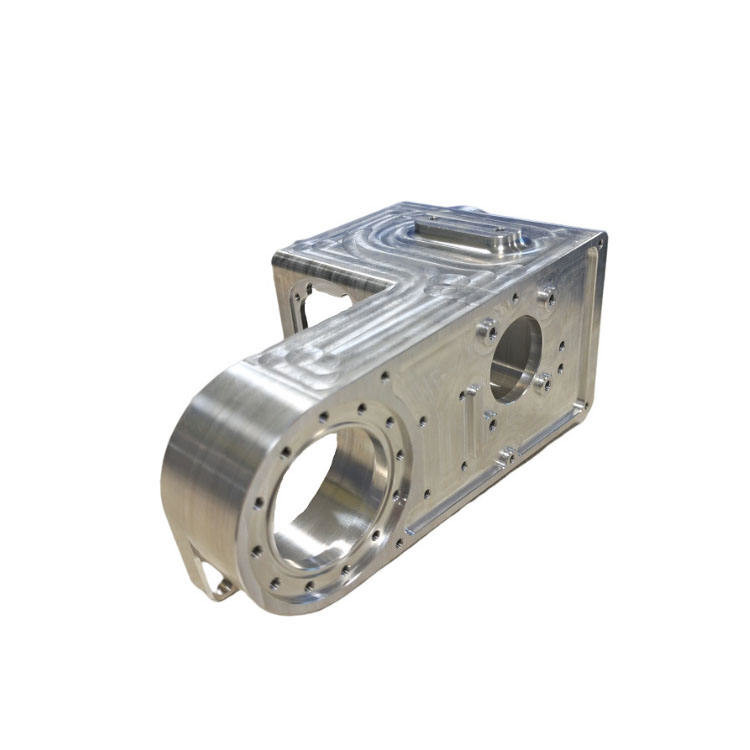

Confused about CNC machining parts for waveguide filters? Whether they can be crafted effectively is crucial for many. Let’s find out if CNC machining can meet the demand for waveguide filters.

Yes, CNC machining parts are available for waveguide filters, providing precision and customizability. This method ensures high-quality components that meet specific design and performance requirements.

When you’re diving into waveguide filters, ensuring precision in machining can't be overlooked. CNC machining offers the versatility and accuracy needed, making it a great fit for producing parts that demand tight tolerances and complex designs.

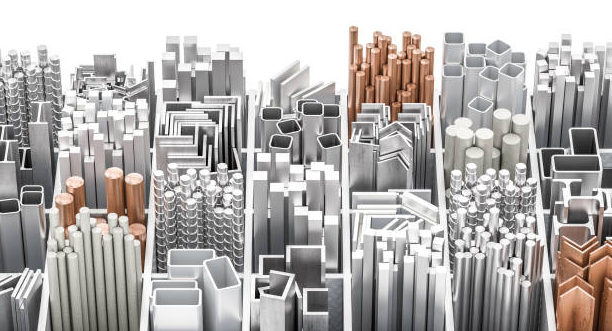

What Materials Are Available For Waveguide Filters?

Choosing the right material can prevent common issues in manufacturing. With so many options, how do you decide which materials best suit waveguide filters?

Material options for waveguide filters include aluminum, copper, and brass. These materials offer excellent conductivity and durability, tailored to specific functional requirements.

Selecting the material for waveguide filters hinges on several factors. Aluminum is lightweight and cost-effective, providing a solid choice for many applications. Copper, known for its superior electrical conductivity, becomes essential for filters needing efficient signal transmission. Meanwhile, brass offers corrosion resistance, making it ideal for harsh environments. The choice depends on your specific needs. Here’s a summary of material options for waveguide filters:

| Material | Conductivity | Cost | Durability | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum | Moderate | Low | Good | Moderate |

| Copper | High | Moderate | Excellent | Moderate |

| Brass | High | High | Excellent | High |

What Is The Tolerance For Waveguide Filter Machining Components?

Worried about achieving the precise dimensions needed? Understanding tolerances is key to successful component manufacturing.

Tolerances for waveguide filter components are typically tight, often around ±0.02 mm to ensure precise alignment and functionality.

In the CNC machining of waveguide filters, achieving tight tolerances is crucial. The precision here ensures that every component aligns perfectly, maintaining the filter's effectiveness. A typical tolerance of around ±0.02 mm is standard but can be adjusted based on specific design requirements. This precision helps in maintaining signal integrity and performance. Remember, quality checks are paramount, ensuring every element meets these high standards.

How to produce CNC Machining Parts for Waveguide Filters?

Curious about the process of creating CNC parts for waveguide filters? Knowing the steps can clarify much before starting production.

The process involves designing with CAD software, selecting appropriate materials, CNC machining, and quality inspection to ensure each part meets specifications.

Producing CNC parts for waveguide filters begins with an accurate design using CAD software. This design includes every detail of the component layout. Once the design is ready, selecting the right material follows, considering factors like conductivity and durability. The CNC machine then carves out parts with precision. After machining, we conduct quality inspections every two hours to check dimensions and adherence to the standards. This vigilance minimizes errors and ensures consistent quality, addressing potential issues swiftly.

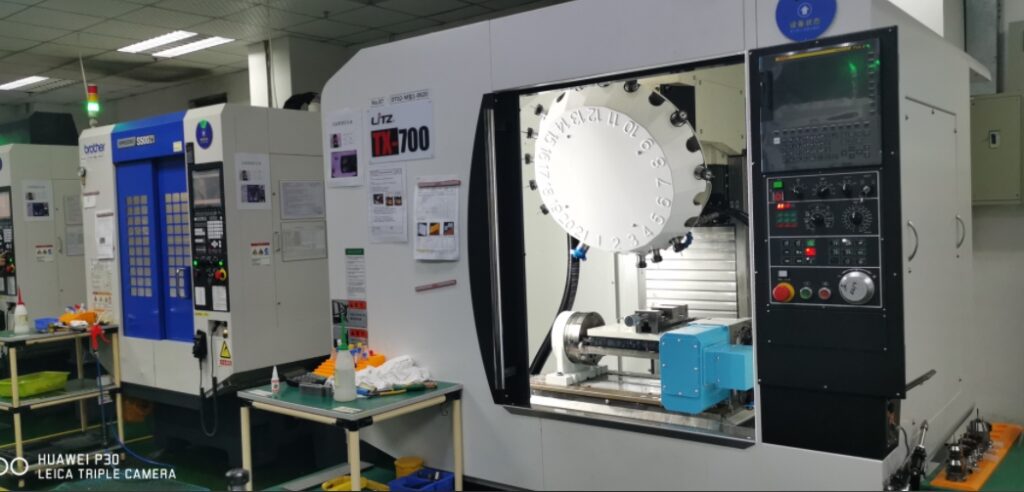

What Can Sunjoy Do for Waveguide Filter Metal Components?

Thinking about partnering with a reliable producer? Knowing what Sunjoy offers can ease your decision-making process.

Sunjoy provides precision CNC machining, reliable quality checks, and customizable solutions for waveguide filter components, focusing on consistent quality and timely delivery.

At Sunjoy, we pride ourselves on delivering exceptional service for waveguide filter components. Our highly skilled team works closely with clients, understanding their unique requirements. With extensive experience in producing parts with tight tolerances, we ensure precision at every step. Regular quality checks, conducted every two hours, monitor dimension consistency, reducing the risk of defects. By blending technical expertise with top-tier machinery, Sunjoy supports your project with reliable and innovative solutions.

Conclusion

CNC machining is ideal for waveguide filters, offering precision, quality, and material flexibility. Choose the right partner for success.