Metal stamping often looks straightforward, but is it really simple or more complex? Many wonder about the real challenges behind the process.

Metal stamping is generally simple once the machine is set up properly and materials are well-prepared. Regular quality checks by engineers ensure dimensions and quality remain consistent.

The metal stamping process can seem daunting at first glance, with heavy machinery and fast-moving parts. But the truth is, if you set up the machine correctly and prepare your material carefully, the actual stamping becomes quite manageable. Still, without proper checks, things can go wrong quickly. I learned early on that consistency in material flatness and frequent quality inspections are what keep everything running smoothly.

What Are the 7 Steps in the Stamping Method?

It can feel overwhelming to learn all the steps in stamping. What are these key steps that make the process work?

The stamping method usually involves seven main stages: blanking, punching, bending, embossing, coining, drawing, and trimming. Each step shapes the metal to the desired form with precision.

These seven steps break down the complex process into simple actions:

| Step | Description |

|---|---|

| Blanking | Cutting a flat piece of metal from sheet |

| Punching | Creating holes or shapes by driving a punch |

| Bending | Forming the metal by folding or curving |

| Embossing | Adding raised or recessed designs |

| Coining | Precision pressing to shape or texture metals |

| Drawing | Stretching the metal without tearing |

| Trimming | Removing excess material for final shaping |

Each step modifies the metal in a way that builds on the previous. Knowing these helps anyone see how a flat sheet can transform into detailed parts without fuss if the process is controlled well.

What Are the Problems with Metal Stamping?

Sometimes when I work with stamping, problems pop up. What common issues come with this process?

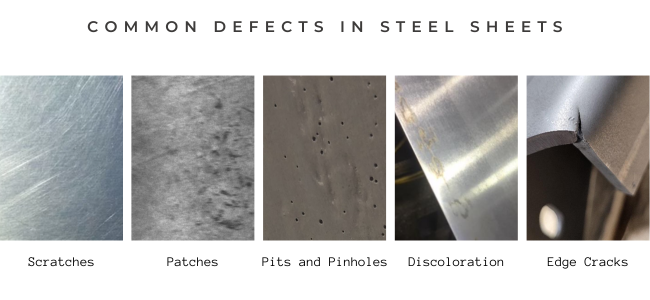

Metal stamping problems often come from poor material quality, machine wear, or incorrect settings. Defects like warping, cracking, or uneven cuts can appear, impacting the final product.

Problems mainly arise when:

- The metal sheet is uneven or contaminated.

- The die or punch becomes dull or damaged.

- Machine parameters like pressure or speed are off.

- Lack of regular inspections to catch early defects.

To avoid this, I always make sure the material surface is smooth and flat. Quality engineers step in regularly to check dimensions and spot any defects early. This proactive approach keeps errors minimal and lowers scrap rates.

Which of the Following Stamping Dies Is the Most Complicated?

Choosing the right stamping die is important, but which one is the toughest to work with?

Progressive dies are generally the most complicated stamping dies. They perform multiple operations in one process as the metal moves through each station.

Here’s why progressive dies stand out:

| Die Type | Complexity Level | Key Features |

|---|---|---|

| Simple Die | Low | Performs one operation only |

| Compound Die | Medium | Combines two or more operations |

| Progressive Die | High | Multiple steps at different stations |

Progressive dies are challenging because they require precise timing and alignment for each step. They also need careful design to make sure every station performs perfectly without jamming or misfeeds. I have seen firsthand how setting up a progressive die takes more time but pays off in efficiency during high-volume production.

How Hard Is It to Stamp Metal?

I often get asked, how difficult is metal stamping really for someone new? Is it something anyone can pick up?

Stamping metal is not overly hard once you understand the basics and follow good practices. The key challenges are machine setup, selecting quality materials, and careful monitoring during production.

A beginner can face issues like inconsistent cuts or machine jams, but these diminish with experience. Consistent material flatness and frequent quality checks make a huge difference. From my experience, once you master the machine parameters and keep a close eye on quality, stamping becomes a routine task with reliable results.

Conclusion

Metal stamping is simple when machines are well-set, materials flat, and quality is regularly checked.