Precision in robotic components can make or break the efficiency and aesthetics of the final product. How do you ensure that your robots not only function well but also look appealing?

Precision milled metal offers excellent accuracy and surface finish, crucial for the high-performance demands of robotics. It delivers consistent quality, essential for crafting components that meet stringent specifications, whether for function or appearance.

Balancing the visual appeal with functionality propels robotic manufacturing to new heights. Here, I explore the nuances of utilizing precision milled metal in robotics.

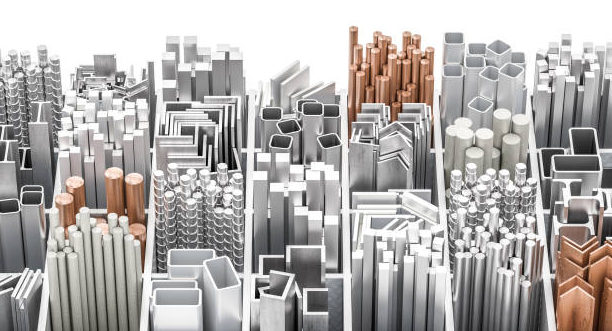

What is the best metal for robotics?

The choice of metal can significantly impact a robot's efficiency. Do you know which metals strike the perfect balance between durability and weight?

Aluminum is often considered the best metal for robotics due to its light weight and resistance to corrosion. It's versatile, offering strength without compromising on the agility of the robotic components.

In my experience, aluminum excels in environments demanding both aesthetic appeal and practicality. Its ability to be finely milled ensures intricate parts fit seamlessly, which is critical for maintaining movement precision. Alternating between these metals can depend on the specific requirements of the project:

| Metal | Pros | Cons |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Not the strongest |

| Steel | Very strong, durable | Heavier, may rust |

| Titanium | Strong, corrosion-resistant | Expensive, harder to machine |

Each choice involves trade-offs between weight, strength, and cost, requiring decisions tailored to your robot's needs.

What is the strongest material to build robots?

Strength underpins a robot's longevity and robustness. Finding materials that offer superior strength is key. But what ultimately defines the strongest construction material?

Carbon fiber composites are incredibly strong, offering exceptional strength-to-weight ratios. They outpace traditional metals in terms of tensile strength and flexibility, making them ideal for demanding applications.

I have seen carbon fiber allow for innovative designs previously impossible with metals alone. The reduced weight can lead to improved energy efficiency, which is crucial for battery-powered robots. This material opens up new possibilities in robot design:

| Material | Strength | Weight | Cost |

|---|---|---|---|

| Carbon Fiber | High | Very light | Expensive |

| Steel | High | Heavy | Moderate |

| Aluminum | Moderate | Light | Affordable |

Opting for materials like carbon fiber can enhance performance but requires investment in terms of cost and specialized handling.

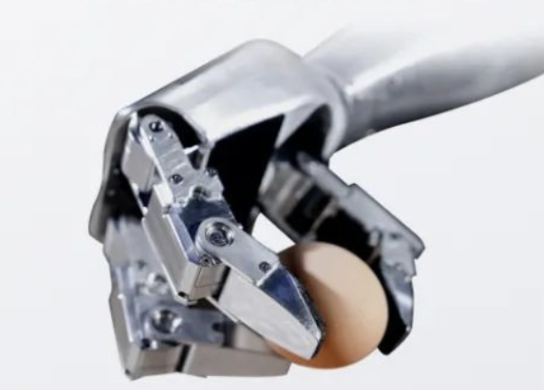

What is precision of movement in robotics?

Achieving seamless movement is vital for robots to perform tasks accurately. What factors contribute to the precision of a robot's movements?

Precision of movement in robotics hinges on precise engineering and high-quality components, ensuring smooth and accurate operations. It's driven by factors such as gear design and sensor integration.

From my perspective, leveraging advanced sensor technologies and finely-milled mechanical parts creates a fluid and controlled movement system. This precision is crucial for robots performing intricate tasks, where exact placement and timing are non-negotiable. The focus on detail results in enhanced productivity:

| Aspect | Importance |

|---|---|

| Gear Design | Ensures smooth power transmission |

| Sensor Integration | Provides accurate feedback for control |

| Lubrication | Reduces wear, ensures smooth motion |

With these elements in place, robots can tackle even the most challenging applications with confidence.

What is the best material for robot arms?

The robot's arm serves as the primary point of interaction with tasks and materials. But what material guarantees both functionality and durability?

Titanium is often the best choice for robot arms, offering an ideal mix of light weight and immense strength. It's resistant to fatigue, making it suitable for repetitive tasks.

When working with clients who prioritize longevity and reliability, I've found titanium to be unparalleled. It's particularly effective in environments demanding a long lifecycle and consistent performance without deformation:

| Material | Features | Ideal Use Case |

|---|---|---|

| Titanium | Strong, lightweight, corrosion-resistant | High-stress environments |

| Steel | Durable, abrasion-resistant | High-impact settings |

| Aluminum | Lightweight, flexible | Low-stress applications |

Selecting the right material for robotic arms is often a balancing act between cost, weight, and application needs.

Conclusion

Precision milled metal enhances robotic performance with accuracy and durability, while materials like aluminum and carbon fiber offer strength and lightness suited to varied robotic needs.