China Aluminum CNC Machining Manufacturer

Precision Aluminum Machining Services with Factory Direct Pricing

Precision Machining

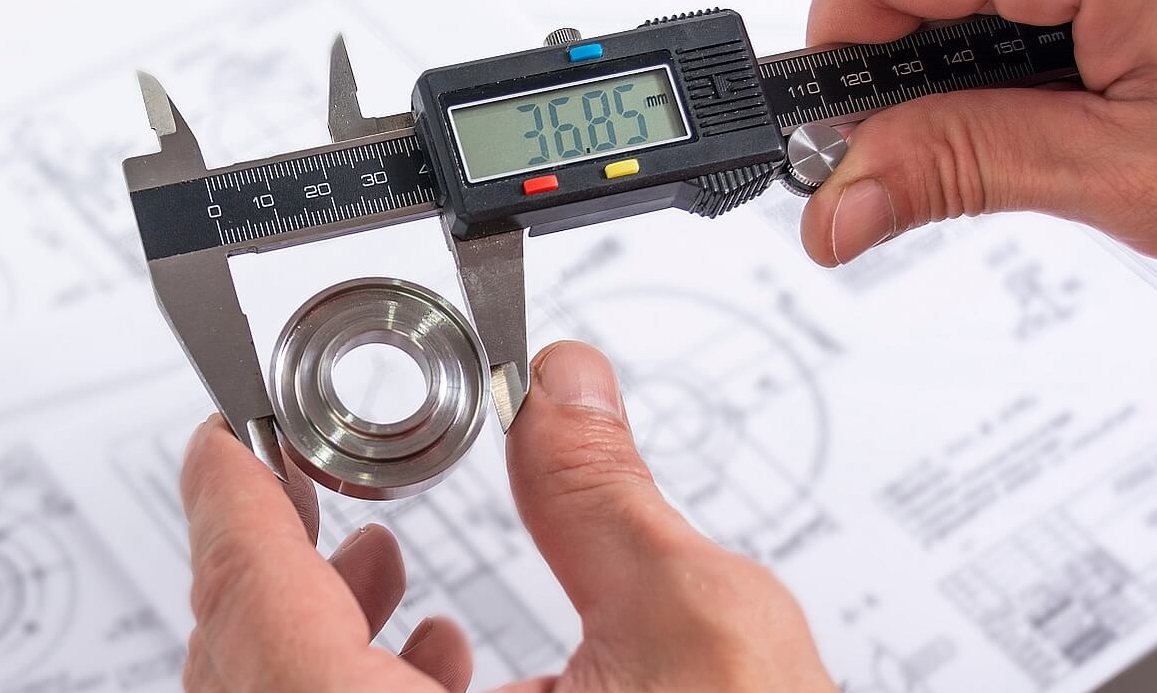

Tolerance up to ±0.01mm

Mass Production

50,000 pcs each month

Low MOQ

Starting from 2pcs

One-Stop Service

From design to delivery

Core Service Areas

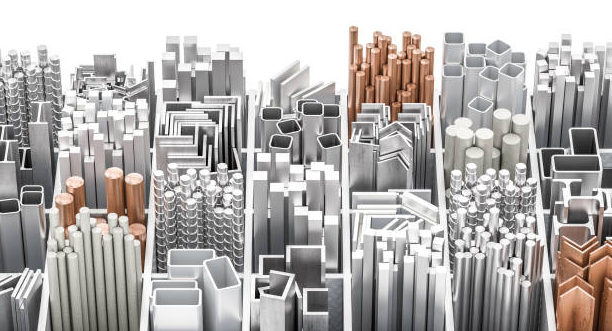

We provide comprehensive CNC machining processing solutions, from raw material choosing to surface treatment, meeting the needs of various industries

CNC Programming

- Skilled Programmers: at least 20 years of experience to set CNC program.

- Advanced Equipments: Brother CNC machines, 5-axis machines, CMM.

- CNC Tool: High precision, durability, efficiency, versatility, heat resistance.

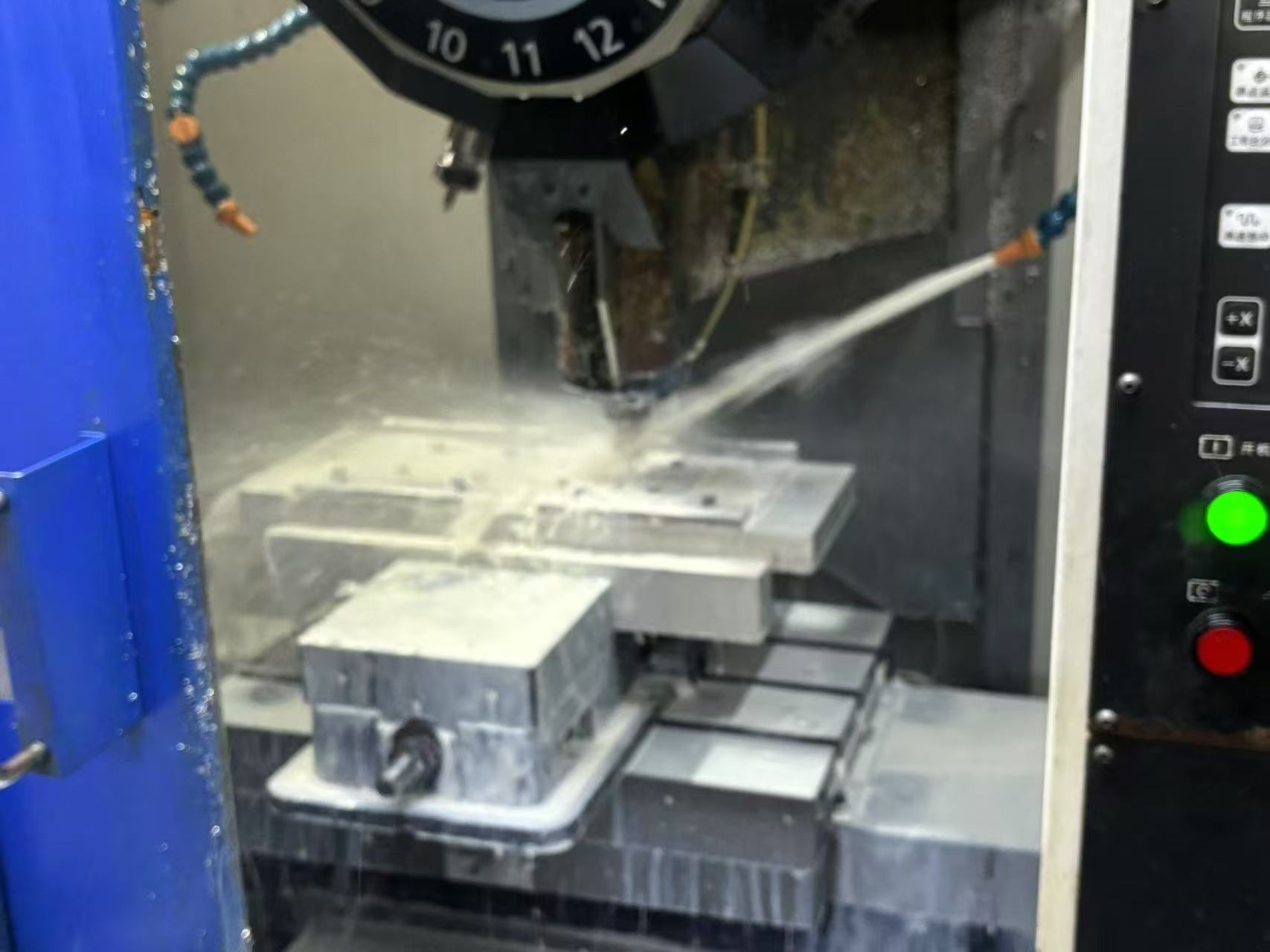

CNC Precision Machining

- Processing Capabilities: Milling, drilling, turning, tapping, etc.

- Technical Parameters: Tolerance, surface roughness, etc.

- Equipment List: 5-axis CNC and other advanced equipment

Surface Treatment Services

- Anodizing: Various color options and thickness specifications

- Powder Coating: Process workflow and durability

- Other Treatments: Electrophoresis, wood grain transfer, etc.

Assembly and Integration Services

- Component Assembly: Precision assembly and quality assurance

- Quality Control: Full process monitoring and inspection

- Packaging & Logistics: Custom packaging and global shipping solutions

Industry Application Cases

Explore our innovative solutions across various industries with proven success stories

Automotive Parts

Our precision aluminum components have helped reduce vehicle weight by 15%, improving fuel efficiency while maintaining structural integrity.

Computer & Electronic

Our thermal management solutions have increased cooling efficiency by 30% in data centers, reducing energy consumption and operational costs.

Telecommunications

High-precision parts for network infrastructure, communication devices, and telecom equipment that demand reliability and durability.

New Energy

Our lightweight yet durable mounting systems have supported 50MW of solar installations across diverse climate zones, withstanding extreme weather conditions.

LED Lighting Solutions

Our aluminum heat sinks & precision components for LED lighting have extended product lifespan by 40% while enabling sleeker designs for commercial and residential applications.

Drone & Robot

High-precision drone and robotic components ensure accurate navigation, stability, and efficiency for autonomous operations