CNC machining is revolutionizing lighting manufacturing, but how does it contribute to sustainability? Discover the practices that could reshape our approach to eco-friendly production.

CNC machines achieve sustainability by optimizing material use, producing precise cuts with minimal waste. These machines reduce scrap material and energy usage, driving efficient production processes in sustainable lighting manufacturing.

CNC machining offers transformative potential, but understanding its environmental impact requires a deeper look into its mechanisms and practices.

What are the sustainable practices of CNC machines?

CNC machining has long been seen as resource-heavy, but recent practices are shifting perceptions. How are these machines contributing to more sustainable production?

The sustainable practices of CNC machines include precision cutting to reduce waste, recycling of materials, and using energy-efficient machinery. These techniques optimize resources, aligning with eco-friendly production goals.

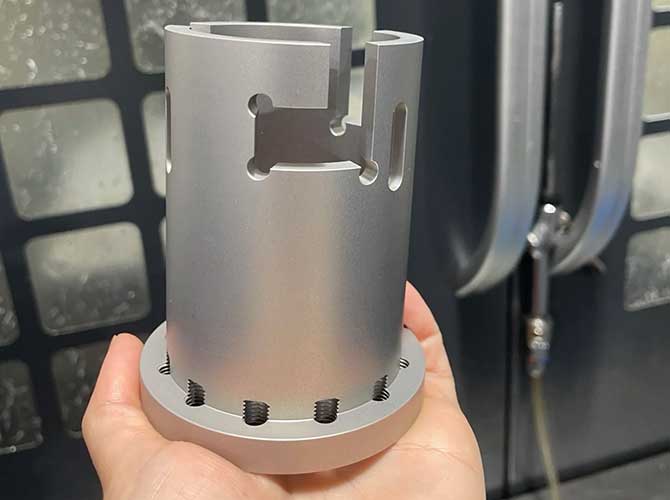

CNC technology embraces eco-conscious innovations, which dramatically improve manufacturing practices. For instance, precision cutting ensures materials are utilized to their fullest potential, reducing leftover waste. Material recycling further enhances sustainability, allowing industries to recover and reuse valuable resources.

Moreover, newer CNC models incorporate energy-efficient technology, effectively lowering electricity consumption. Manufacturers can tap into advanced software to monitor energy usage, identifying further efficiency opportunities.

By integrating these sustainable practices, CNC machines not only support eco-friendly production but also position themselves as key players in the fight against environmental degradation.

What is the most environmentally friendly lighting?

Choosing environmentally friendly lighting options can significantly impact sustainability efforts. Which lighting choices make the biggest difference?

LED lighting stands out as the most environmentally friendly due to its energy efficiency, long lifespan, and minimal hazardous materials use. It consumes less power and emits fewer greenhouse gases than traditional lighting.

LED lights consume up to 75% less energy compared to incandescent bulbs. Their extended lifespan further reduces waste, with fewer replacements required over time. Unlike CFLs, LED lights don't contain mercury, minimizing environmental harm.

The shift to LEDs aligns with global sustainability initiatives, targeting lower energy consumption and reduced carbon footprints. When combined with CNC-produced lighting components, the ecological benefits multiply, promoting a synergistic approach to sustainable lighting solutions.

What is the energy efficiency of a CNC machine?

Energy efficiency is central to CNC machine operations. How do these machines fare in energy consumption?

CNC machines boast considerable energy efficiency by utilizing advanced motors, minimizing idle times, and enabling precise operations that decrease overall power consumption in production sectors.

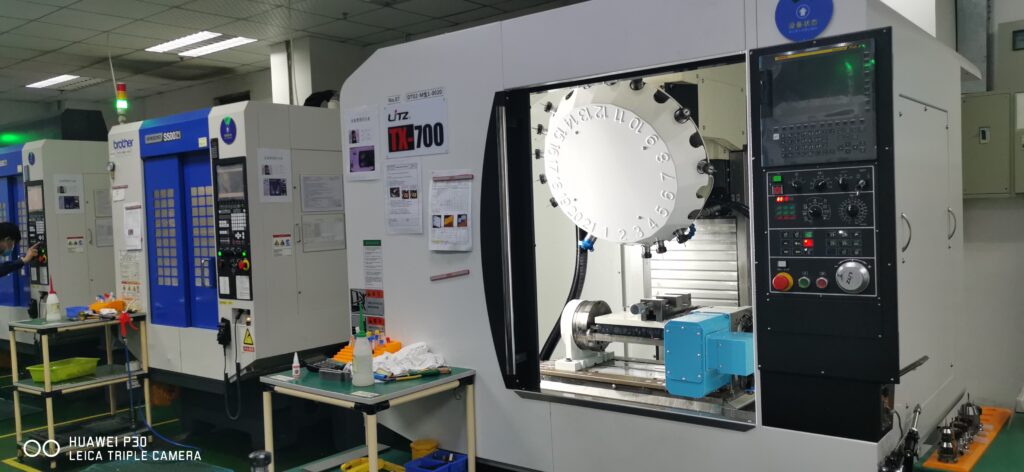

Modern CNC machines are designed with energy-saving motors that intelligently adjust power based on operational demands. Reduced idle times are achieved through efficient programming, which ensures machines only consume power when necessary.

Precision in CNC operations plays a pivotal role in energy efficiency. With accurate tool paths and minimized rework, these machines significantly cut down on unnecessary energy expenditure. This leads to not only ecological advantages but also cost savings in production.

Such energy-efficient practices reinforce CNC machines as a cornerstone of sustainable industrial developments, highlighting their integral role in eco-conscious manufacturing.

How does CNC machining affect the environment?

The environmental implications of CNC machining are complex. What are the key environmental impacts of these advanced machines?

CNC machining affects the environment through energy consumption and material waste. However, recent advancements focus on reducing emissions, enhancing recycling efforts, and promoting eco-friendly practices in machining operations.

The direct environmental impacts of CNC machining include energy use and potential waste generation. However, innovations like energy-efficient models and enhanced recycling programs mitigate these concerns.

CNC machines utilize environmentally harmful cutting fluids, but green alternatives are increasingly available. These bio-based coolants minimize ecological damage while maintaining operational effectiveness. Enhanced recycling processes ensure metal shavings and other by-products are reclaimed and reused.

Utilizing such green practices minimizes CNC machining’s environmental footprint, demonstrating a shift towards responsible manufacturing that prioritizes ecological health and resource conservation.

Conclusion

CNC machining in lighting is a game-changer for sustainability, reducing waste, boosting energy efficiency, and aligning with eco-friendly objectives.