Tolerances in CNC machining can make or break your lighting assembly. Precision is everything, but it’s often overlooked.

Understanding CNC machined tolerances is crucial for ensuring your lighting assembly functions properly. Tight tolerances guarantee fit and function, while loose ones may lead to assembly issues or failure.

Without proper control, much can go wrong. Let’s break down why it's essential to pay attention to tolerances.

Why Are CNC Machining Tolerances Important?

Ignoring tolerances can lead to costly errors. Imperfect parts may not fit, causing delays and additional expenses.

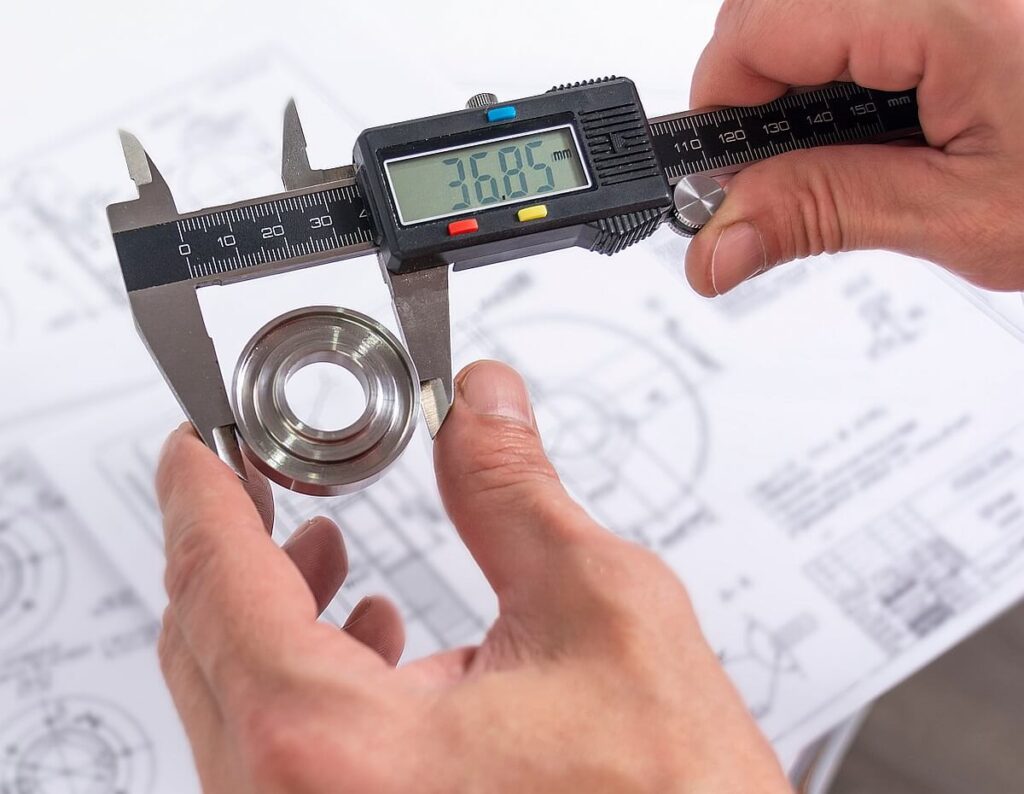

Tolerances determine how much variance is allowed in part dimensions. These are crucial in ensuring parts fit together smoothly, maintaining functionality and aesthetic quality.

It's about mastering the balance between precision and cost. Let's delve deeper into how to achieve this balance.

Finding the Right Balance

| Tolerance Level | Cost | Application |

|---|---|---|

| Tight | High | Essential components |

| Medium | Moderate | Most assemblies |

| Loose | Low | Non-critical areas |

Striking the right balance in tolerance levels is key to efficiency and cost-effectiveness. High precision is necessary for critical parts, but not every part needs this. Evaluate where you can allow looser tolerances without sacrificing quality. Sounds simple, but it’s a careful calculation involving design requirements and production capabilities.

How Do Tolerances Affect Lighting Assembly?

Tolerances directly influence assembly accuracy. Even a slight miscalculation can lead to big issues.

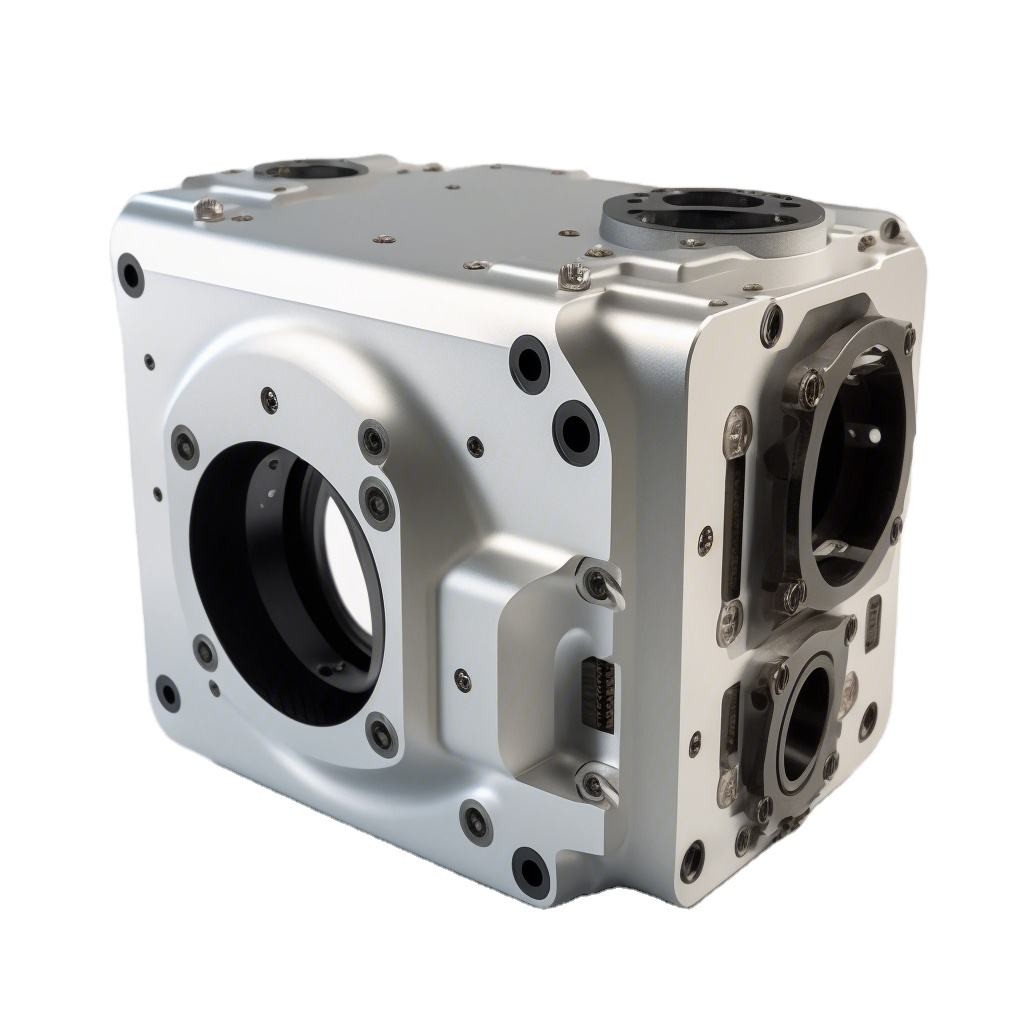

Tolerances affect the alignment, fit, and stability of lighting assemblies. Proper tolerances ensure that parts fit perfectly, preventing misalignment and preventing early wear and tear.

Ensuring the fit means thinking ahead. Let’s look at common problems you might encounter.

Light fixtures need precision for both function and form. Misalignment leads to uneven lighting or fixtures not fitting securely. Parts with incorrect tolerances may cause vibration, reducing the lifespan. Solving these issues calls for both understanding and anticipation. Anticipating these problems during the design phase avoids headaches later. Keep an eye on the critical areas requiring tighter tolerances and allocate resources accordingly.

How Can CNC Tolerances Improve Cost-Effectiveness?

Balancing cost and quality forms the backbone of successful manufacturing. It’s an art and a science.

CNC tolerances help control manufacturing costs by optimizing material use and reducing waste. With precise tolerances, fewer errors occur, cutting down on costly rework and scrap.

Managing costs while maintaining quality is a delicate dance. Let's explore how to effectively execute this.

Implementing a Cost-Effective Strategy

Focus on areas where precision is most needed. Reducing tolerance ranges in non-essential parts can lower expenses without affecting the overall product quality. A well-planned approach enhances product integrity while controlling manufacturing costs. Begin with a comprehensive review of each part’s function and required precision. Create a hierarchy of critical vs. non-critical parts. By applying appropriate tolerance levels, you'll find an elegant solution that satisfies both budget and design standards.

What Role Does Technology Play in Managing Tolerances?

Technology drives progress in part manufacturing accuracy, ensuring parts meet specifications efficiently.

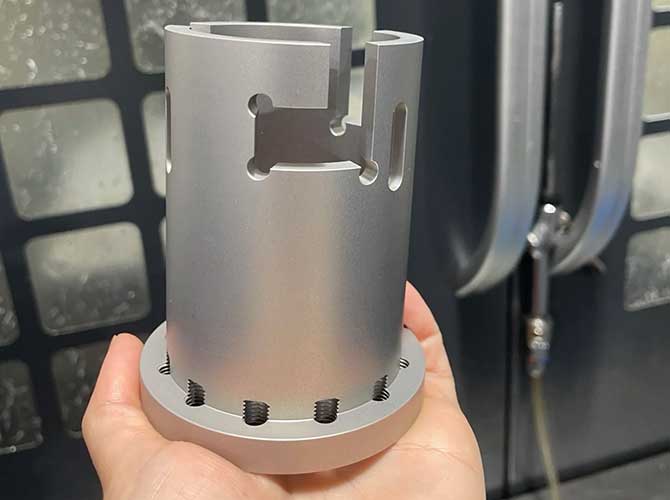

Advanced CNC machines equipped with the latest technology ensure that all parts are machined to precise tolerances, enhancing overall product quality and assembly speed.

Embracing technology is more than just adopting the latest trends. It’s a strategy for excellence.

Leveraging Technology for Precision

Modern CNC machines come with features like real-time monitoring and automated adjustments. These technologies enhance precision, allowing quick detections of deviations and immediate corrections, reducing waste and cost. Train your team on new technologies to maximize their potential, fostering a culture of continuous improvement. As you embrace these changes, expect smoother operations and improved assembly outcomes. Investing in the right technology today leads to fewer errors and greater efficiencies tomorrow.

Conclusion

Mastering CNC tolerances is crucial for efficient and cost-effective lighting assembly, combining precision with practicality.