Sheet metal forming is a common process in manufacturing, but understanding its benefits and drawbacks can be tricky for many.

Sheet metal forming offers fast production speed and cost savings, making it ideal for high-volume manufacturing. However, it may face challenges like material springback and tooling wear.

If you’re new to manufacturing or considering sheet metal forming for your projects, knowing its strengths and weaknesses is important. Before diving deeper, it helps to explore questions about coating, stamping issues, metal choices, and bending differences. These all affect the final product and cost.

Why does a metal sheet need to be coated before using?

Protecting metal sheets from rust, corrosion, and surface damage is critical in production.

Coating metal sheets prevents rust, enhances durability, and improves aesthetic appeal, which extends the life of stamped parts.

Coating acts like a shield for metal sheets. If the sheet is uncoated, it may quickly rust or degrade during forming or later use. This causes flaws or failures in products. Common coatings include zinc (galvanizing), paint, or powder coating. Each type has its own benefits and considerations depending on the application. Some coatings also protect tooling by reducing friction during stamping and bending processes. Knowing why coating is needed helps avoid costly defects and keeps the metal’s surface smooth and strong.

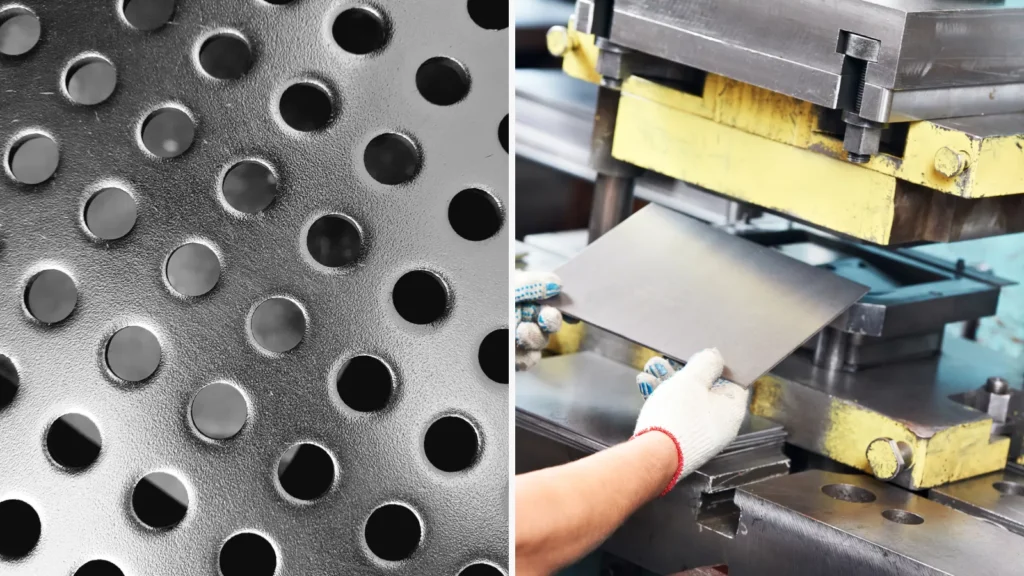

What are the problems with metal stamping?

Metal stamping is fast and efficient but not without challenges that can impact quality.

Problems in metal stamping include die wear, burr formation, springback, and misalignment, which can cause defects or increase costs.

Stamping uses powerful dies to shape metal, but this process wears tools down over time. Worn dies lead to poor cuts and surface issues like burrs or rough edges. Springback, where metal tries to return to its original shape after forming, can lead to imprecise parts. Misalignment of dies or sheets causes inconsistent results and scrap parts. These problems increase the need for maintenance, quality checks, and sometimes rework. Managing them well requires careful tool design, good material choice, and regular inspections to keep production flowing without hiccups.

What metal is good for stamping?

Choosing the right metal affects the ease and quality of stamping.

Soft metals like aluminum, copper, brass, and low-carbon steel are good for stamping because they bend easily and resist cracking.

Different metals respond differently during stamping. Soft metals allow smooth deformation and form sharper details without breaking. Aluminum is lightweight and corrosion-resistant, often used in electronics and automotive parts. Copper and brass offer good conductivity plus stamping ease. Low-carbon steel is popular for its balance of strength and malleability. Harder metals like stainless steel can be stamped too but require more force and tougher tools. Selecting the right metal upfront can reduce stamping problems, speed up production, and improve finished part quality.

What is the difference between bending and stamping sheet metal?

Bending and stamping both shape metal sheets but work in very different ways with different results.

Bending bends the sheet along a straight axis to create angles, while stamping punches or cuts shapes by pressing the metal inside a die.

Bending is a simpler process that forms metal by rotating it around a die or using a press brake. It produces straightforward shapes like folds, lips, or channels. Stamping is more complex and can create holes, forms, or decorative patterns by using shaped tools pressing into the sheet. While bending changes the angle or curve of the sheet, stamping can add or remove sections, change thickness locally, or emboss designs. Both processes can be combined in a manufacturing line, but understanding their differences helps choose the right method for the part’s function and design needs.

Conclusion

Sheet metal forming offers fast, cost-effective production but requires careful attention to coating, metal choice, and process challenges like stamping and bending.