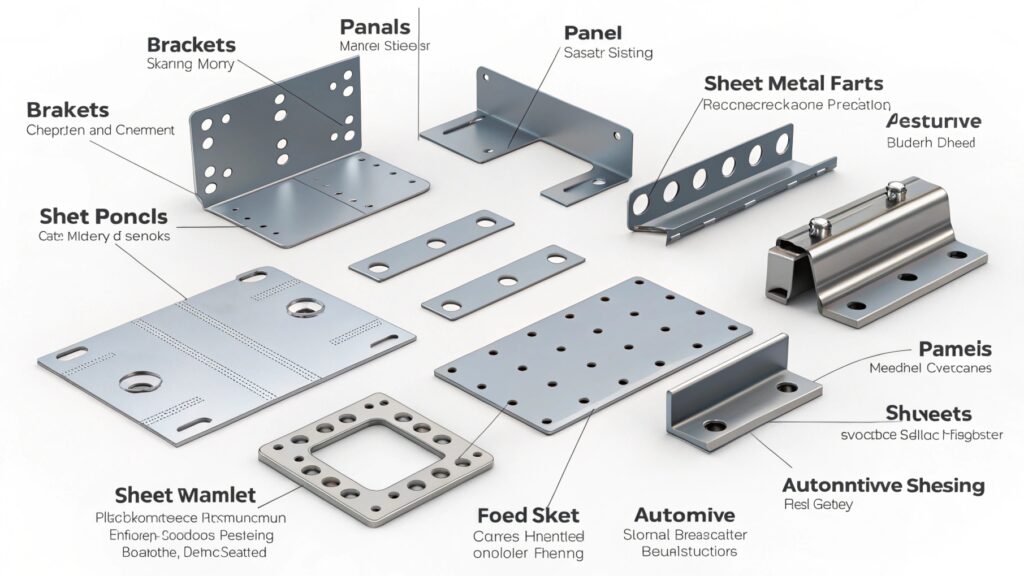

Sheet metal parts are essential in countless industries, acting as the backbone for various products. They're crucial for efficiency and functionality.

Sheet metal parts are mainly used for electronics enclosures, automotive components, building structures, and household appliances, providing structural support and protection, enhancing durability and aesthetic appeal.

Sheet metal's versatility means it's used in everything from consumer electronics to automobiles. This adaptability encourages exploration of its myriad uses in diverse industries.

What is sheet metal mainly used for?

Sheet metal's primary role is creating durable components that withstand pressure and environmental factors. It's an integral part of manufacturing.

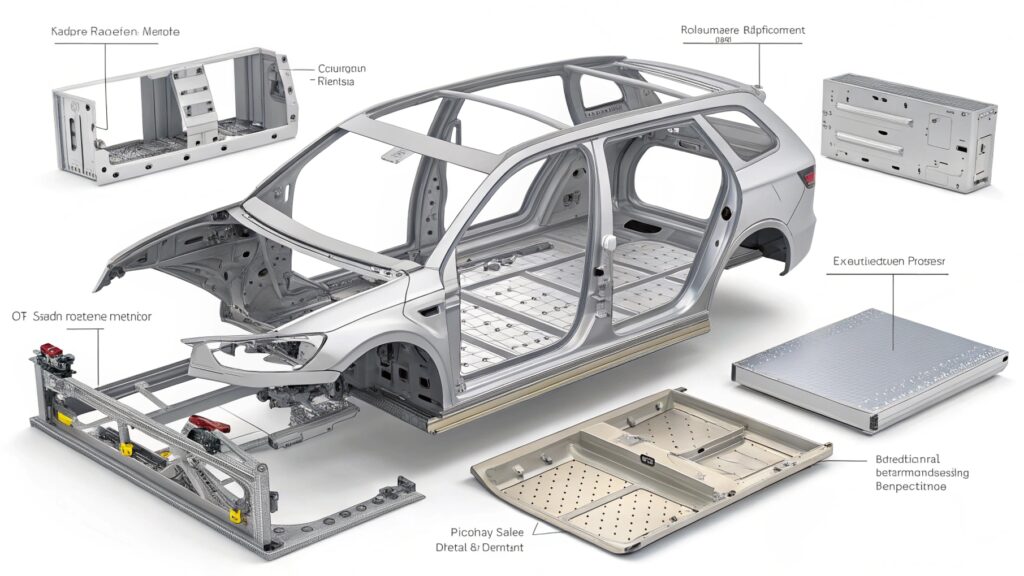

Sheet metal is primarily used in construction for building structures and automotive industries for parts, due to its strength and flexibility, meeting safety standards efficiently.

In construction, sheet metal supports infrastructure, offering resistance against weather. It's pivotal in automotive production, forming car bodies and frames. Its pliability and robustness make it suitable for challenging environments. Regulations ensure safety and performance, pushing for innovations in its applications.

What are the industries that use sheet metal bending?

Sheet metal bending is central to manufacturing, enabling complex designs. It's crucial for production efficiency and design flexibility across industries.

Industries using sheet metal bending include aerospace, electronics, automotive, and construction, creating complex shapes for functionality and aesthetic goals in robust products.

In aerospace, precision in sheet metal bending is vital for crafting components resistant to extreme conditions. Electronics benefit from intricate designs for enclosures. Automotive sectors require optimized shapes for better aerodynamics and styling. Construction uses sheet metal bending to create resilient structures. The demand for shape diversity pushes innovation in bending techniques.

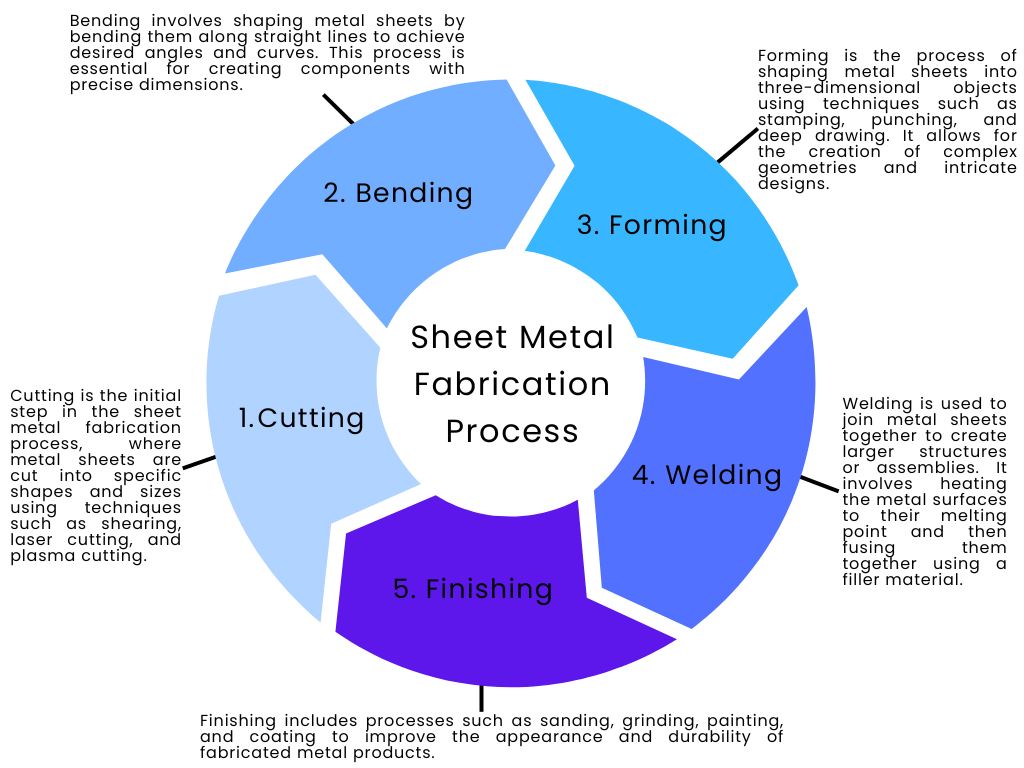

What are the 5 sheet metal operations?

Understanding sheet metal operations is key to mastering its applications. Each technique influences product design and function.

Five main operations in sheet metal are cutting, bending, punching, welding, and finishing, crucial for optimizing designs, improving product durability and meeting specific aesthetic requirements.

Cutting and bending define shape, allowing designers to turn concepts into viable products. Punching creates holes for fasteners, essential for assembly efficiency. Welding joins parts, vital for structural integrity. Finishing involves smoothing surfaces to enhance durability and appearance. Each operation complements the others, ensuring finalized products meet standards.

What are two things that sheet metal is often used for?

Sheet metal serves diverse purposes, highlighting its importance in everyday life and high-stake industries. Its applications are broad yet vital.

Sheet metal is often used for creating enclosures for electronic devices and structural components in vehicles, ensuring safety, functionality, and aesthetic appeal.

Enclosures protect delicate electronics from external factors, enhancing device longevity. In vehicles, sheet metal offers structural integrity, affecting safety and performance. Its practicality blends functionality with design. Sheet metal's adaptability to different shapes and environments underscores its pivotal role across applications.

Conclusion

Sheet metal's versatility spans industries, providing essential structural support and innovative designs that adapt to changing needs.