In today's fast-paced tech world, precision and efficiency are crucial. Discover how CNC machining boosts projector parts with speed and accuracy.

CNC machining offers projector parts high precision, rapid production, and enhanced aesthetics. It ensures optimal heat dissipation, making components reliable and efficient.

CNC machining transforms projector part production by increasing precision, speed, and part quality. It's fascinating to see how it enhances both performance and efficiency.

What Materials Are Ideal for CNC Machining Projector Parts and Why?

Choosing the right material can make or break your project's success. Quality materials are key to durable projector parts.

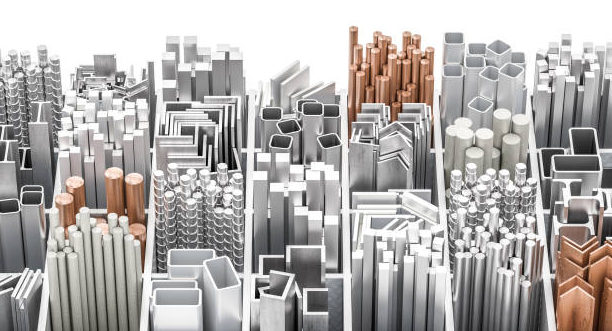

Metals like aluminum, brass, and steel are excellent for CNC machining projector parts. These materials offer strength, durability, and superior thermal conductivity, crucial for efficient heat management.

Aluminum is lightweight and offers excellent heat dissipation.

Brass provides superb corrosion resistance

Steel ensures strength.

For projector parts, metal choice impacts overall functionality. Consider these factors: thermal properties, machinability, and cost versus benefit ratio. CNC machining processes cater to different material specifications ensuring quality and precision.

What Surface Finishes Are Good for Projector Parts?

Surface finish impacts not just aesthetics, but function too. A smooth finish can enhance projector parts in unexpected ways.

Opt for finishes like anodizing, powder coating, or bead blasting. These improve corrosion resistance, enhance appearance, and ensure better thermal conductivity for projector parts.

Anodizing adds a protective layer, making the surface more resistant to wear. Powder coating provides a durable, attractive finish, while bead blasting smooths surfaces, reducing friction and improving heat transfer. Every choice in surface finish impacts projector longevity and performance. Consider factors like environmental exposure, thermal management, and aesthetic requirements.

How To Control the Quality for Projector CNC Machining Components?

Quality assurance is vital for flawless functioning. Discover practical ways to maintain top quality in CNC machining.

Quality control involves precise measurements, regular inspections, and adherence to tolerance standards. Employ advanced CAD software and inspection tools to uphold high-quality production standards.

Our engineers checked the every single product size during the cnc turning production. This can control the dimension within the tolerance all the time.

Utilize meticulous CAD design, ensure accurate programming, and conduct rigorous inspections. Employ coordinate measuring machines for precise checks. Document each step and iteration, keeping quality consistent. Balancing technology with skilled oversight ensures projector parts meet all specifications, from fit and finish to functionality and reliability.

What Tolerance Can Sunjoy Achieve with CNC Machining?

Tolerance defines the precision in part fabrication. Sunjoy's mastery in CNC machining achieves impressive results.

Sunjoy can achieve tight tolerances as small as ±0.01mm. This precision ensures parts fit perfectly, optimizing performance and reliability for intricate projector components.

Achieving such tight tolerances requires state-of-the-art equipment and expertise. CNC machines employ high-resolution tools and fine controls to ensure precision. Sunjoy implements rigorous testing and quality checks to verify each component’s adherence to specified tolerances. The result is seamless integration in projector systems, ensuring optimal function and performance.

Conclusion

CNC machining revolutionizes projector parts with precision, speed, and quality. Choosing the right materials and finishes enhances durability and performance.