Navigating the complex world of CNC machining can be daunting. Finding the right approach is the key to efficiency and precision.

For effective CNC machining, ensure optimal tool selection, maintain precise calibration, and implement thorough testing. These steps guarantee accuracy, minimize waste, and speed up production, supporting industries like automotive and medical.

Mastering CNC machining techniques opens doors to precision and quality, essential for meeting diverse industry demands. Let's explore the materials, processes, challenges, and applications tied to CNC machining, revealing insights for industry success.

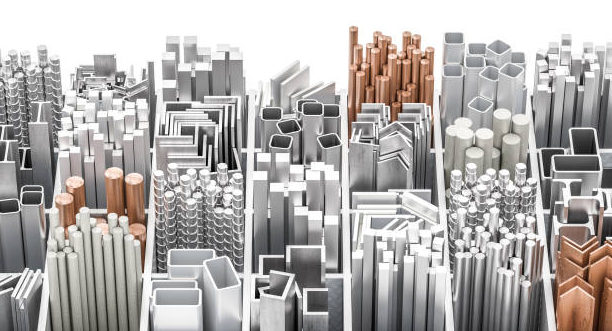

What Materials are Commonly Used in CNC Machining?

Choosing the right material for CNC machining is a pivotal decision. Material properties impact product performance and production efficiency.

Common materials include metals like aluminum and stainless steel, and plastics like ABS and polycarbonate. Each has unique properties catering to specific industry needs, balancing strength with machinability.

Deciding on the ideal material involves assessing factors like durability, cost, and application purpose. Here's a quick look:

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Electronics, automotive parts |

| Stainless Steel | Strong, heat-resistant | Medical devices, aerospace |

| ABS Plastic | Strong, versatile | Consumer electronics, prototypes |

The choice of material must align with functional requirements, budget constraints, and desired product lifespan, ensuring the effective deployment of CNC machining.

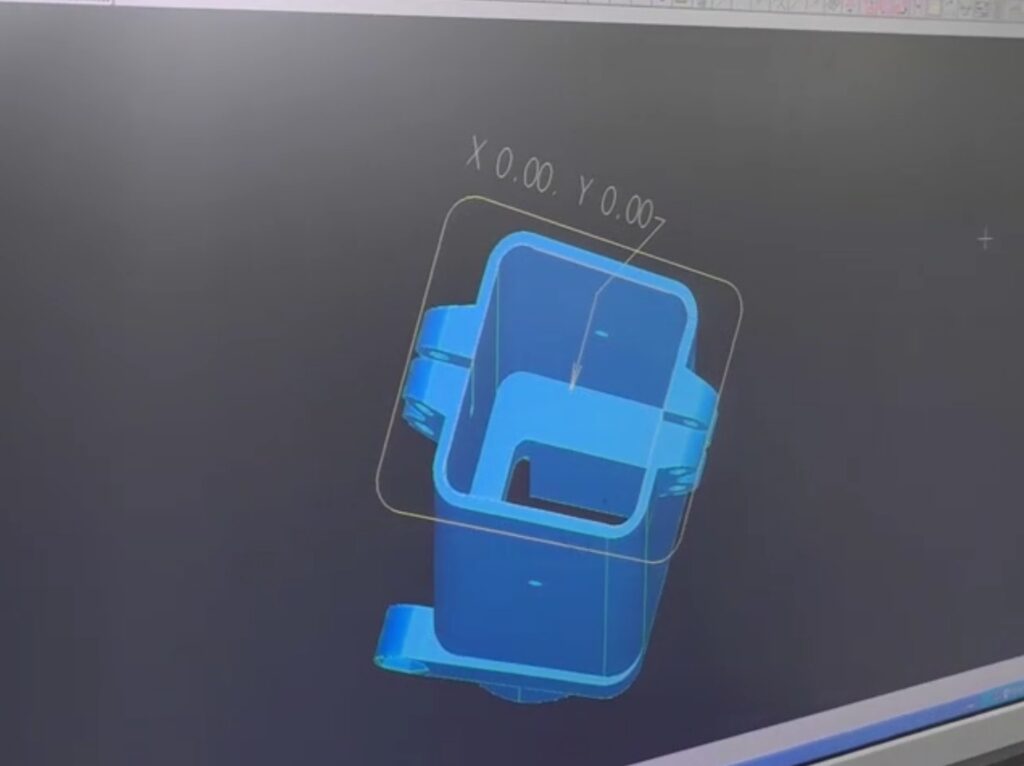

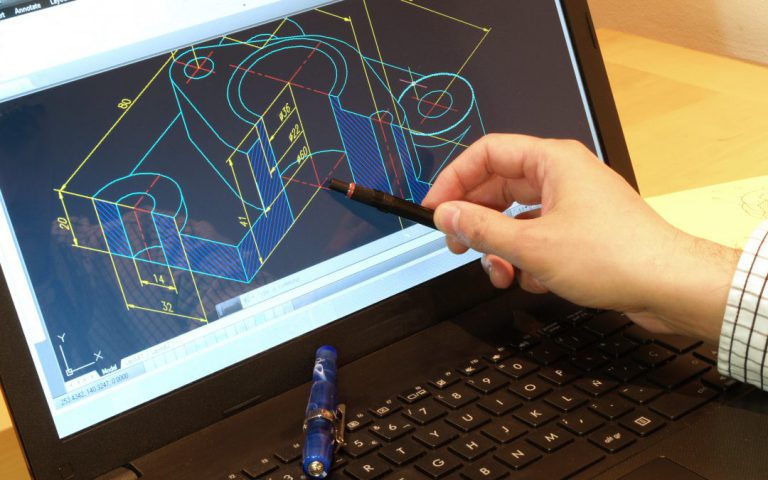

What is the CNC Machining Process?

Understanding the process is essential for precision and efficiency. Without it, errors and wastage increase, impacting output quality.

The CNC machining process begins with designing in CAD, followed by programming, setup, and cutting. Each step ensures components meet specifications, enhancing accuracy and production speed.

Going deeper into each step helps:

- CAD Design: Create detailed models, optimizing for machinability.

- Programming: Convert designs to CNC compatible formats.

- Setup: Choose and install appropriate tools and materials, calibrating machines accurately.

- Cutting: Execute precise movements using programmed paths.

This workflow ensures consistent quality, reduces errors, and maximizes productivity, delivering high-precision parts across industries.What are the Common Challenges in CNC Machining?

Challenges in CNC machining often lead to costly complications without proper management. Identifying them can save time and resources.

Common challenges include tool wear, material inconsistencies, and programming errors. Addressing these requires regular maintenance and accurate programming to prevent costly downtime and defects.

Overcoming these hurdles involves strategies like:

- Routine Maintenance: Regularly check and replace worn tools.

- Calibration: Ensure machines are calibrated for consistent accuracy.

- Training: Equip operators with skills to adapt to technological changes.

Implementing these tactics mitigates risks, enhancing reliability in CNC operations and fostering high-quality output.What are the Applications of CNC Machining?

The versatility of CNC machining revolutionizes production across sectors. Understanding its applications can optimize its use.

CNC machining is used in automotive, medical, consumer electronics, and aerospace industries. It allows for intricate designs, precision, and scalability, crucial for innovative product development.

Applications span:

- Automotive: Custom parts, prototypes, and bulk production.

- Medical: Precision surgical instruments, implants with strict tolerances.

- Consumer Electronics: Smartphone components, enclosures crafted with fine detail.

These applications demonstrate CNC machining’s role in boosting production capacity, ensuring product quality, and driving technological advancement.Conclusion

Effective CNC machining hinges on material selection, process understanding, and challenge management, enhancing industries from automotive to medical with precision and efficiency.