Facing the intricate challenge of building amplifiers can be daunting. Understanding the key metal stamping components is crucial for success in this specialized field.

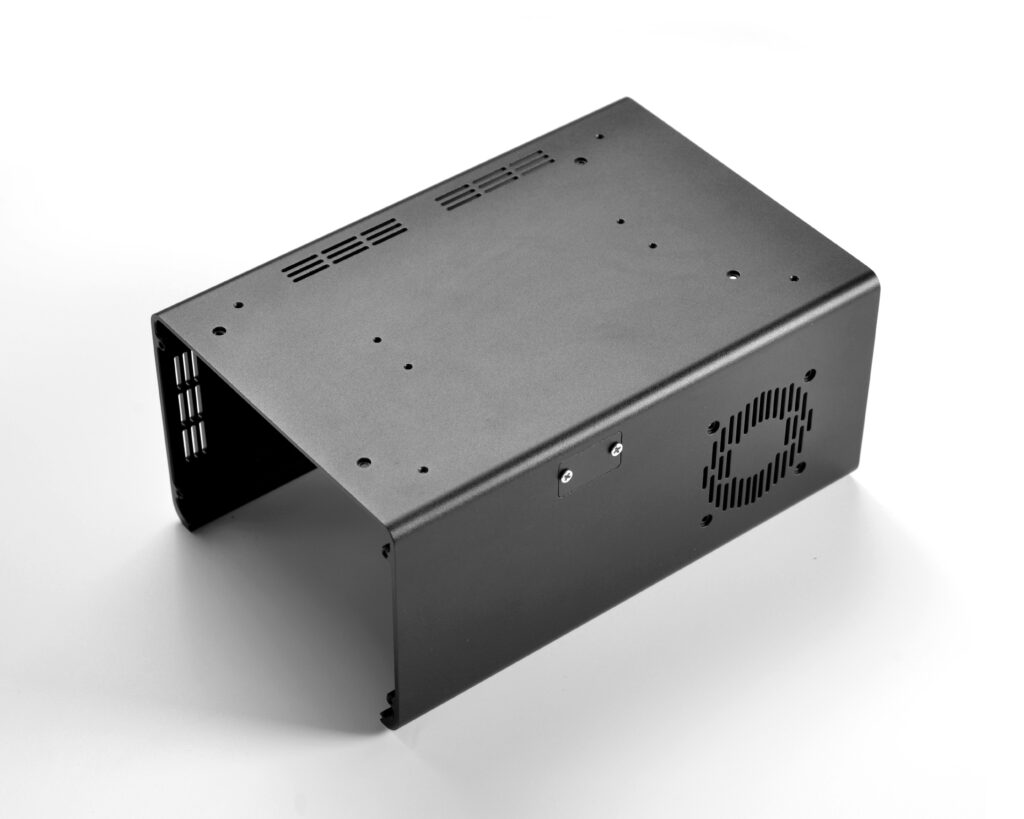

Amplifiers typically rely on metal stamping for parts like bases and covers, ensuring precise dimensions and structural integrity. This process uses a press machine to shape metal sheets into specific designs required for the amplifier construction.

When building an amplifier, knowing what goes into the construction makes the process more manageable. Let's explore this further.

What is the process of metal stamping?

Creating delicate designs from sturdy metal seems impossible. Yet, metal stamping transforms this idea into reality with precision and speed.

Metal stamping involves placing a flat metal sheet into a press machine, controlled by a die, to bend or form precise shapes. This allows for mass production of consistently shaped components with the desired aesthetic and functional properties.

Understanding metal stamping requires breaking down its steps: First, selecting the right material is vital. Then, it’s about configuring the die with exact patterns. Finally, the press machine exerts controlled pressure to shape the metal. This process is efficient and can produce intricate designs consistently. With advanced CNC technology, you can achieve even better precision, allowing innovations in designs and cost-efficiency.

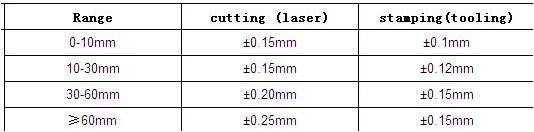

What is The Tolerance Metal Stamping Can Achieve?

Need parts with absolute precision? Metal stamping delivers with impressive tolerance capabilities, often surpassing other manufacturing techniques.

Metal stamping can maintain tolerances as tight as ±0.005 inches, allowing for highly detailed designs that meet exact specifications without compromising quality or function.

Tolerance in metal stamping is a game-changer for industries requiring precise components. Comparing methods, stamping stands out with its capability for tighter tolerances. Achieving these depends on factors like material choice, die quality, and machine calibration. These ensure uniformity and reduce waste. For amplifiers, having components within precise tolerances improves sound fidelity and reliability, ultimately enhancing user satisfaction.

What is Sunjoy's Quality System?

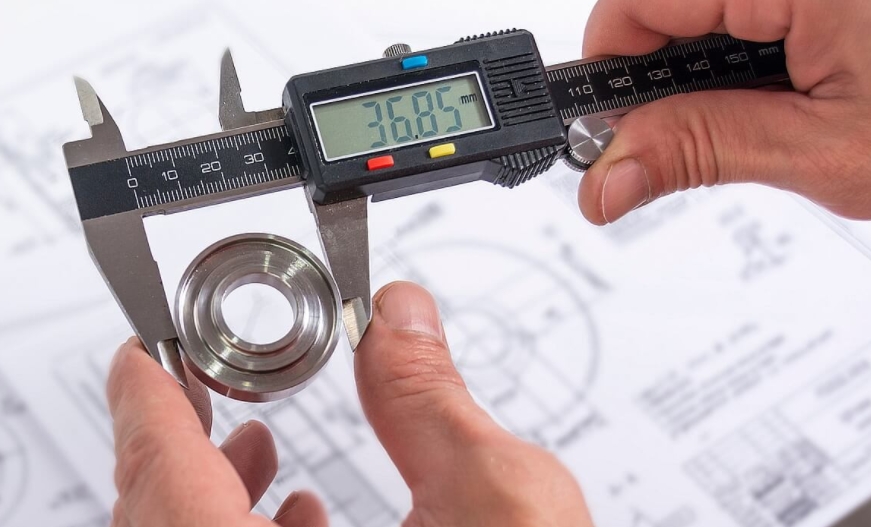

Worried about quality control? Sunjoy’s rigorous system ensures functionality and reliability in every product.

Sunjoy’s quality system adheres to strict protocols involving in-house inspections, certifications, and continuous improvement practices aimed at maintaining top-tier product standards.

Quality isn’t just a word; it’s a commitment we uphold. Sunjoy employs a comprehensive system beginning with material selection, followed by continuous in-line testing during production. Our team is equipped with the latest testing equipment and expertise to detect issues early on. After production, products undergo final inspection ensuring compliance with industry standards. Our ISO certifications reflect commitment to quality, giving clients confidence in each amplifier component we produce.

Can Sunjoy Assemble Amplifiers?

Integrating separate components into a cohesive unit seems challenging. Yet, Sunjoy simplifies amplifier assembly with expertise and care.

At Sunjoy, we provide assembly services, efficiently transforming stamped parts into complete amplifiers, ensuring seamless functionality and ease of use.

Assembly goes beyond mere component fitting; it’s about creating harmony in operation. Sunjoy takes pride in assembling bases and covers for amplifiers. Our experienced technicians follow precise procedures ensuring perfect alignment and connection of each piece. With rigorous testing post-assembly, we verify operational efficiency and durability, providing clients with a ready-to-use product that meets high industry standards. Offering assembly alongside stamping streamlines production, reducing turnaround times and enhancing product consistency.

Conclusion

Metal stamping in amplifiers ensures precision and durability. Understanding the components, processes, and Sunjoy's quality system helps create amplifiers with trusted reliability.