In today's fast-paced world, industries demand precision and efficiency. CNC machining delivers on both fronts, meeting varied needs across sectors.

CNC machining parts are vital across numerous industries, including aerospace, automotive, and medical. They offer precision engineering, high-quality finishes, and customization essential for modern manufacturing.

Understanding the role of CNC machining in industries can guide businesses in selecting the right processes to meet their production needs.

What are CNC machined parts?

In manufacturing, achieving high precision is a constant challenge. CNC machined parts are designed to solve this problem with unmatched accuracy.

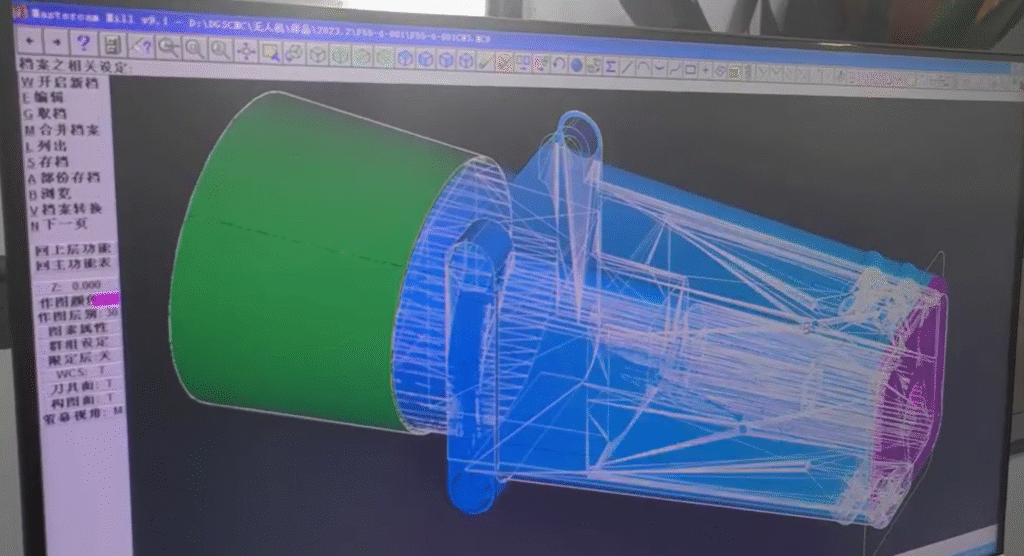

CNC machined parts are components made using computer-controlled machines. These machines help in producing complex designs from metal or plastic with precise measurements, leading to uniformity and high-quality finishes.

CNC machined parts are used widely due to their ability to produce intricate shapes and designs. They are crucial in industries where precision and repeatability are key, such as aerospace, automotive, and electronics. These parts ensure consistency in production, lowering the chance of errors and reducing waste, ultimately saving on costs.

What can CNC machining parts do?

Businesses often wonder about the capabilities of CNC machining. It is the ideal solution for manufacturing complex components efficiently.

CNC machining parts perform a variety of functions, from creating intricate components for electronics to producing durable parts for automotive engines. They are tailored to meet specific industry demands, whether high precision, durability, or aesthetic appeal.

The versatility of CNC machining is one of its major strengths. Industries like medical devices require customization that CNC machines offer, crafting parts that are both intricate and durable. In the automotive sector, these parts ensure that every component meets stringent quality standards. Even in consumer electronics, CNC machining allows for sleek design finishes that attract users. The ability to adapt to different materials, from metals to plastics, further expands its viability across sectors.

How to design parts for CNC machining?

Creating the perfect design for CNC machining can seem daunting. Yet, knowing some design basics simplifies this crucial step.

To design parts for CNC machining, consider material type, complexity, and precision needs. Simplifying designs and selecting the right material can lead to cost-effective and efficient production.

Designing for CNC machining requires attention to detail. Materials influence the machining process, so it's vital to choose wisely based on the desired properties of the final product. Reducing unnecessary complexity in designs improves machining speed and reduces costs. Using CAD software helps visualize the final product, enabling designers to spot potential issues early. Balancing precision with cost considerations ensures the design is both feasible and economical.

How to process a CNC machining part?

Once designs are ready, turning them into a reality involves specific steps. Understanding these steps sets the foundation for successful production.

Processing a CNC machining part involves selecting materials, programming the machine, and performing quality checks. Each stage is critical to ensure the final product meets specifications.

The process begins with material selection, guided by the part’s intended use. Next, programming software translates the design into machine-readable instructions. During machining, the part takes shape as the machine expertly cuts and molds the material. Post-machining quality checks are crucial, confirming the part meets all design specifications and standards. This systematic approach not only ensures quality but also optimizes production time.

Conclusion

CNC machining parts are essential across industries, offering precision and versatility. Adapting designs and processes ensures cost-effective and efficient manufacturing.