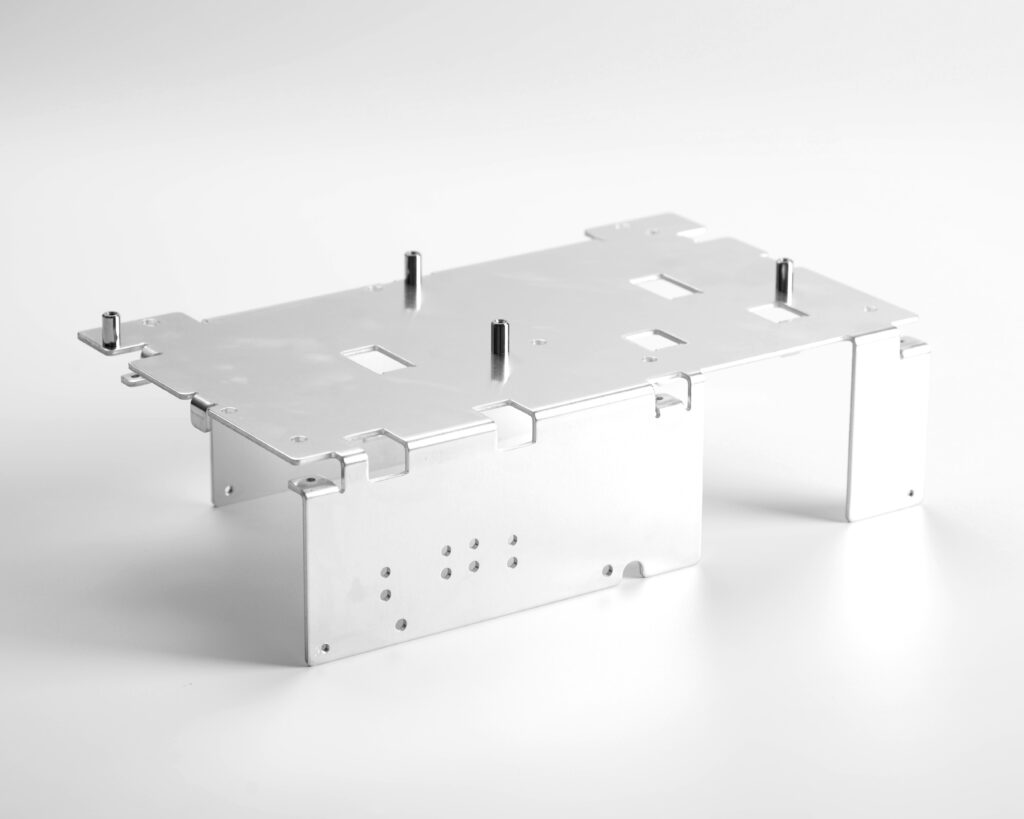

Manufacturers often face the challenge of shaping metal efficiently. This process, known as stamping, transforms metal sheets into specific shapes with precision.

Stamping in manufacturing involves using dies to apply pressure on sheet metal to create desired shapes quickly and accurately. It's a crucial method for producing high-quality metal components and is widely used in various industries.

Metal stamping plays a pivotal role in many sectors, but understanding its nuances can be complex. Dive in to explore the intricacies of this essential manufacturing technique.

Is metal stamping hard?

Navigating the complexities of metal stamping can be daunting. The precision required adds to the challenge.

Metal stamping involves precise operations which require detailed understanding and expertise. While it can be complex, advances in technology simplify the process, making it more accessible and efficient than ever.

Metal stamping may seem hard due to its precision and detail. However, tools like CNC machines have revolutionized the field. With adequate training and understanding of the equipment, even intricate designs can be stamped efficiently. By leveraging these technological advancements, manufacturers streamline processes and reduce errors, leading to optimized production.

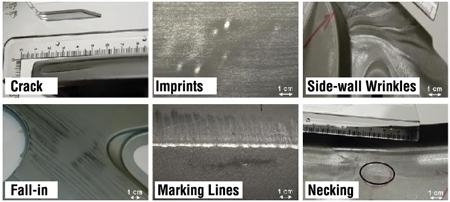

What are the problems with metal stamping?

Manufacturers often encounter several challenges with metal stamping, impacting productivity and quality.

Problems with metal stamping include tooling wear, material inconsistencies, and issues with maintaining precision in high-volume production. Addressing these requires proper maintenance and material selection to ensure consistent quality.

| Understanding the problems involved in metal stamping is crucial. Common issues like tooling wear can lead to downtime and increased costs. Choosing the right materials and regular maintenance are key solutions. Here’s a table highlighting typical problems and their solutions: | Problem | Solution |

|---|---|---|

| Tooling wear | Regular maintenance schedules | |

| Material inconsistency | Quality checks and material sourcing | |

| Precision challenges | Advanced CNC technology |

These strategies help mitigate issues, ensuring smooth operations and maintaining product quality.

What metal is best for stamping?

Selecting the right metal is crucial for optimal stamping results.

The best metals for stamping include aluminum, copper, and stainless steel. These materials offer a balance of strength and malleability, making them ideal for precision shaping and durability.

Choosing the right material is essential for successful metal stamping. Aluminum is known for its lightweight and malleability, making it easy to shape. Copper offers excellent conductivity and durability. Stainless steel provides a robust option for components requiring strength and resistance to corrosion. Each metal has unique properties that make it suitable for different stamping applications, ensuring versatility and quality in production.

Is metal stamping expensive?

Manufacturers weigh costs carefully when considering metal stamping.

Metal stamping can be cost-effective if done in high volumes due to economies of scale. Initial setup and tooling costs can be substantial, but long-term savings offset these expenses when producing large quantities.

Understanding the cost dynamics of metal stamping is important. While initial tooling can be expensive, mass production balances this out. The fixed costs get distributed across units, making it cheaper per unit over time. Smaller batches might incur higher costs, but for large-scale projects, stamping is a financially viable choice.

Conclusion

Metal stamping is a vital manufacturing process, offering efficiency and precision when properly managed, with challenges mitigated through technology and material choice.