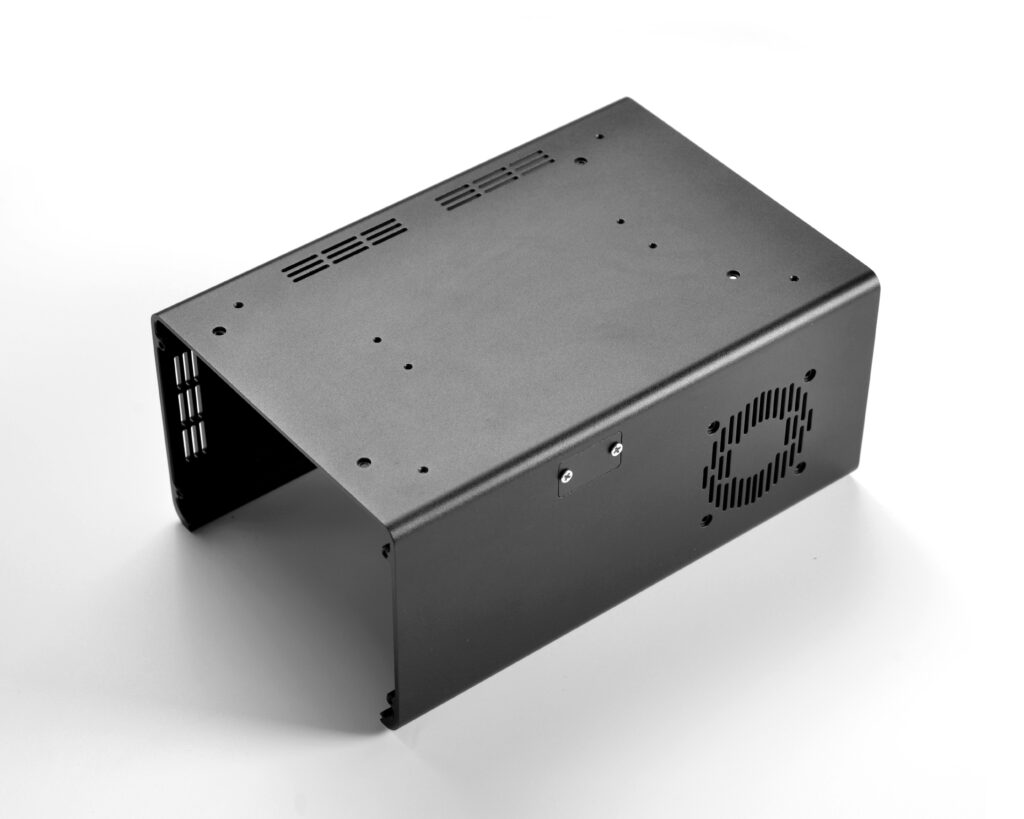

The precision needed for stereo parts can be overwhelming. CNC machining transforms complexity into simplicity, offering unmatched accuracy and beauty in metal components for stereos.

CNC machining provides precision and aesthetic quality in manufacturing stereo parts, whether in small or large quantities. It guarantees accurate dimensions and attractive finishes, essential for high-performance audio equipment.

CNC machining is the magic wand for creating stereo parts that meet exact specifications. By using computer-controlled tools, we achieve high precision and stunning visual appeal, crucial for metal components in stereos. It's particularly beneficial for our European clients, demanding high quality and efficient production.

What Materials Are Ideal for CNC Machining Stereo Parts and Why?

Choosing the right material for stereo parts can be challenging. It influences quality, function, and aesthetics—the core of any great stereo.

Aluminum and stainless steel are ideal materials for CNC machining stereo parts due to their durability, strength, and corrosion resistance, ensuring high-quality and long-lasting components.

Selecting the right materials for stereo parts ensures longevity. Aluminum offers lightweight yet sturdy properties, while stainless steel boasts of strength and resistance to rust. They form the backbone of high-quality audio components, directly affecting sound fidelity and product lifespan. Using these materials, stereo parts resist wear, maintain precision, and deliver uninterrupted audio experiences.

What Surface Finishes Are Good For Stereo Parts?

The finish of stereo parts determines not only aesthetics but also performance. Choosing wisely can elevate the entire audio experience.

Anodizing and powder coating are excellent finishes for stereo parts, providing increased durability, corrosion resistance, and appealing visual quality.

Surface finishes enhance the function and appearance of stereo parts. Anodizing offers a coating that enhances corrosion resistance and wear, while powder coating delivers uniformity and color excellence. These finishes provide practical benefits like protecting components against environmental damage and adding an attractive look, essential for appealing electronics that last for years without losing their touch.

How To Control the Quality for Projector CNC Machining Components?

Maintaining high-quality standards can be tough. Implementing strategies for stringent control is the key to successful CNC machining.

Effective quality control for projector CNC components involves detailed inspections, precise calibrations, and consistent feedback loops to ensure flawless manufacturing.

Quality control in CNC machining is crucial. By conducting rigorous inspections and maintaining calibration standards, I ensure each projector component meets exact specifications. Implementing feedback loops fosters continuous improvement, reducing errors. The goal is producing flawless parts that guarantee reliable projector performance, satisfying even the most demanding clients.

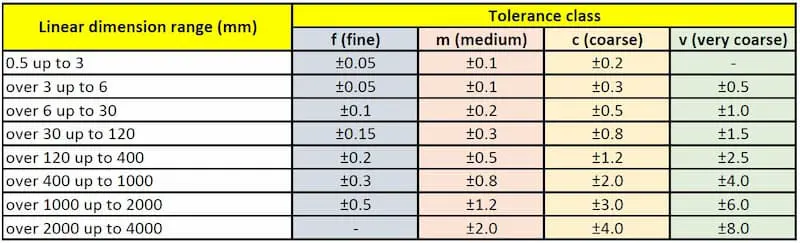

What Tolerance Can Sunjoy Achieve with CNC Machining?

Tolerance precision can define success or failure. High accuracy in CNC machining is crucial for creating reliable stereo components.

Sunjoy achieves a machining tolerance of ±0.001 inches, ensuring precise and dependable stereo parts necessary for high-quality audio systems.

Precision is our hallmark at Sunjoy. Achieving tolerances as tight as ±0.001 inches ensures every part meets stringent standards, shaping accurate stereo components. This meticulous attention to detail results in components that seamlessly fit into audio systems, enhancing sound quality and performance consistency. Trust in precision is vital for stereo part reliability and client satisfaction.

Conclusion

CNC machining revolutionizes stereo component manufacturing with precision, ideal materials, quality finishes, effective controls, and unmatched tolerances.