Every rangefinder promises accuracy, but without the right components, accuracy fades. How do you ensure your rangefinder truly stands out?

For precise rangefinders(include mounting brackets, enclosures, and lens housings), precision metal components like CNC turning and milling, vacuum casting, and sheet metal fabrication parts are essential. These components provide the precision necessary for reliable measurement performance.

When looking at rangefinder components, high precision, durability, and lightweight properties are crucial.

What Are the Precision Components for Precise Rangefinder?

A rangefinder's precision relies heavily on its components. Overlooking these can lead to inaccuracies and user dissatisfaction.

Essential precision components for rangefinders include CNC machined parts, vacuum-cast parts, and sheet metal parts. Each component contributes to the durability and accuracy of the device, making it indispensable for precise measurements.

CNC Machined Parts

CNC machined components are vital for rangefinders due to their tight tolerances and high precision. CNC turning and milling can produce complex geometries, ensuring each part fits perfectly. This precision eliminates measurement errors and enhances the overall quality of the rangefinder.

Vacuum Cast Parts

Vacuum casting is beneficial for creating small, intricate parts that maintain structural integrity. These parts are critical in rangefinders where precision and light weight are necessary. The method allows for the production of components with uniformity, essential for consistency in measurement devices.

Sheet Metal Fabrication Parts

Sheet metal fabrication provides flexibility and strength, crucial for outer casings and internal supports. This method provides robustness while maintaining a lightweight design, which is essential for portable devices like rangefinders. The ease of shaping and durability also ensures long-term performance.

How to Choose a CNC Machined Components Manufacturer for Precise Rangefinders?

Choosing the right manufacturer is often challenging and requires keen attention to detail and quality standards.

Select a manufacturer who specializes in CNC machined components, has a robust quality system, and experience in precision manufacturing. This ensures that the components meet high industry standards and result in a reliable end product.

Critical Factors in Manufacturer Selection

When choosing a manufacturer, consider their experience in CNC production. Look for companies with a proven track record in precision parts for electronics. Examine their quality control measures; certifications such as ISO 9001 indicate high standards. Additionally, consider their ability to meet large-scale production demands, aligning with your project timelines and specifications.

What Can Sunjoy Do for Precise Rangefinders?

ISO9001 Certified, Sunjoy offers exceptional solutions, ensuring that each rangefinder component meets exacting standards and delivers functionality and durability.

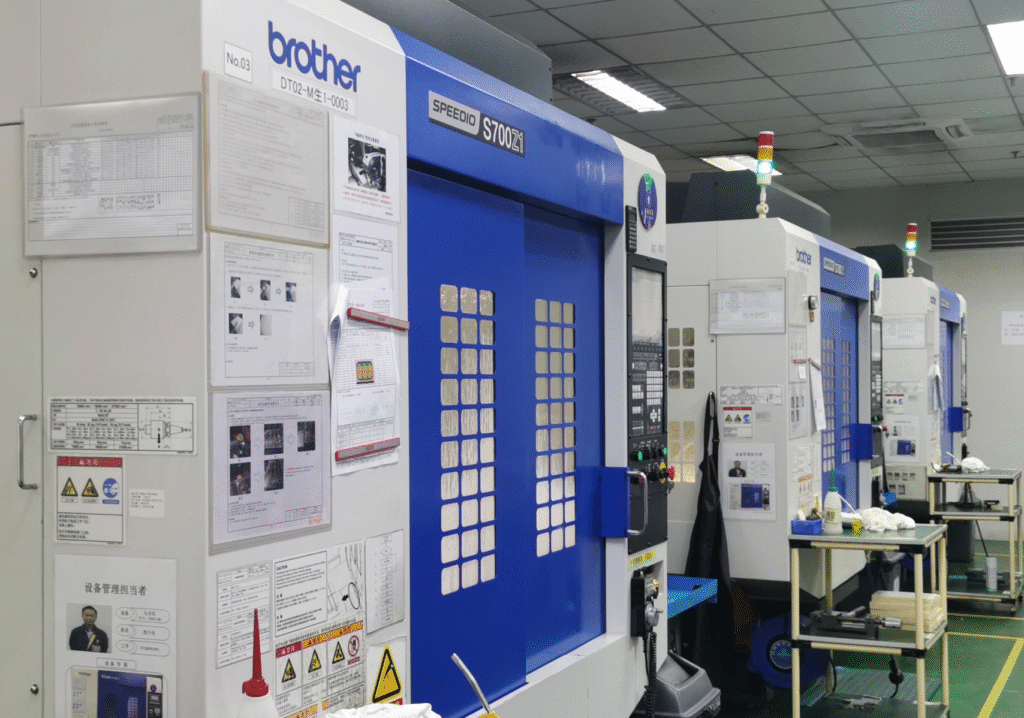

Sunjoy specializes in CNC turning, milling, and sheet metal fabrication, enhancing the precision and quality of rangefinder components. Their capabilities ensure that each part is tailored to meet precise specifications and enhance performance.

Key Offerings

Sunjoy provides high-precision CNC machining services tailored to complex geometries. They excel in producing vacuum cast parts, ensuring small yet intricate component designs meet exact specifications. Their sheet metal fabrication capabilities offer durable, lightweight options essential for rangefinder housings. This combination of services enables them to support precise measurement devices consistently.

What is Sunjoy's Quality System?

A robust quality system ensures that each manufactured component meets industry standards and fulfills client expectations.

Sunjoy's quality system involves rigorous testing and adherence to ISO 9001 standards, ensuring every component is made with precision and reliability. Their commitment to quality guarantees that each product delivered is of the highest standard.

Quality Control Measures

Sunjoy employs stringent quality control measures to oversee the entire manufacturing process. This includes initial inspections, in-process checks, and final product evaluations. The use of advanced measurement tools ensures components meet tight tolerances. Continuous improvement practices, alongside customer feedback, further refine production, maintaining excellence in precision component manufacturing.

Conclusion

Precision metal components, like those crafted by CNC machining, vacuum casting, and sheet metal fabrication, are vital for accurate rangefinders. Sunjoy guarantees precision and quality with its innovative solutions.