Inadequate heat management can drastically shorten LED lifespan, thus affecting performance. Choosing the right heat sink is crucial.

LED lights do need a heat sink. Heat sinks are essential to dissipate heat away from LED components, extending their life and ensuring optimal performance.

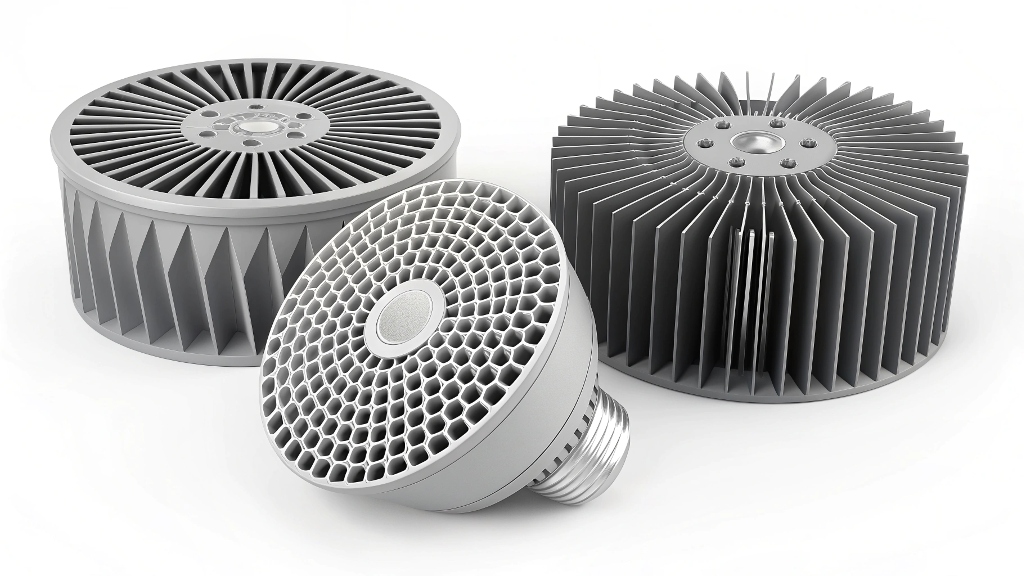

Choosing the right heat sink depends on various factors. The shape, material, and environment where the LED is used play a crucial role. In my experience, understanding these elements is essential for achieving effective heat management and longevity.

Do LED lights need a heat sink?

Excessive heat in LEDs leads to reduced lifespan and efficiency, and managing this heat is vital.

Yes, LED lights require a heat sink. It helps with thermal regulation, allowing LEDs to perform efficiently and last longer.

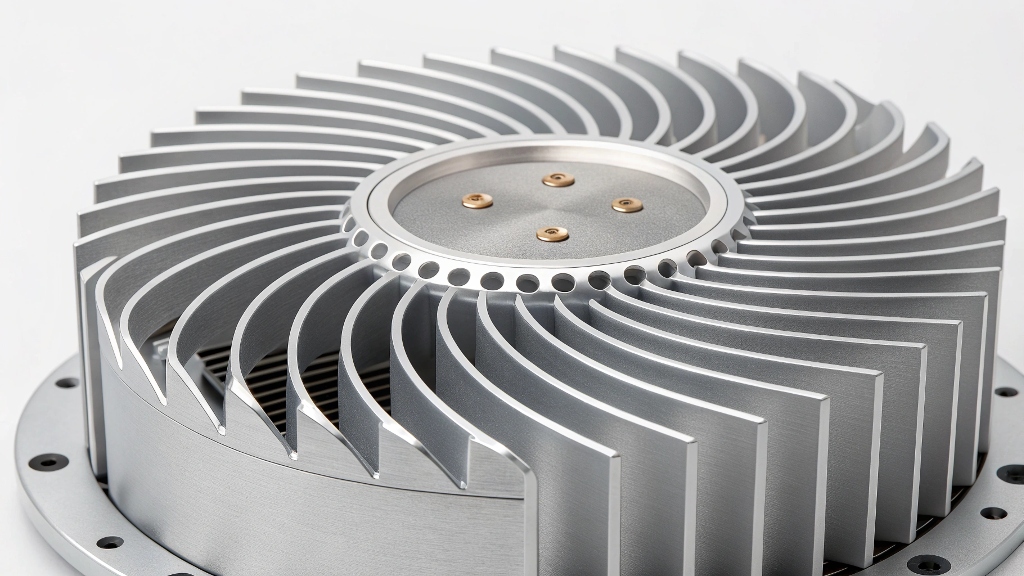

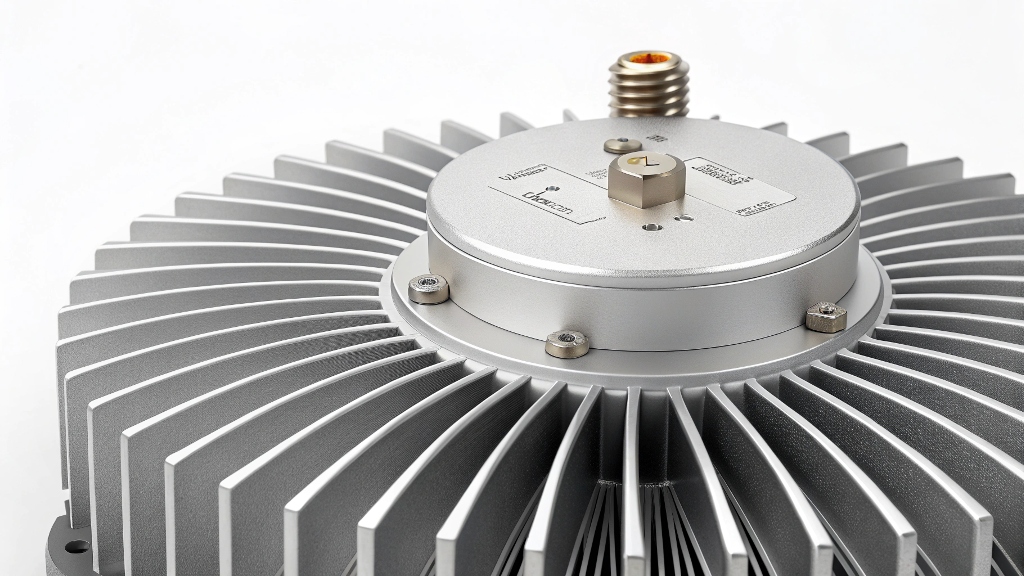

The necessity of heat sinks for LED lights cannot be overstated. LEDs are different from traditional bulbs as they do not emit as much heat in the form of infrared radiation. Instead, any heat generated is managed internally, which can lead to component failure if inadequately controlled. A heat sink helps spread the heat away from sensitive LED parts, preventing overheating. Additionally, using natural convection or forced air cooling can further manage temperatures. Testing and selecting the right heat sink according to the LED's specifications ensures reliable and stable lighting. The choice must be tailored to each application, considering factors like final setup, space constraints, and cooling capacity.

What material is used for LED heat sinks?

Material choice can significantly affect heat sink performance. A material’s thermal conductivity plays a key role.

Aluminum and copper are the most commonly used materials for LED heat sinks due to their excellent thermal conductivity.

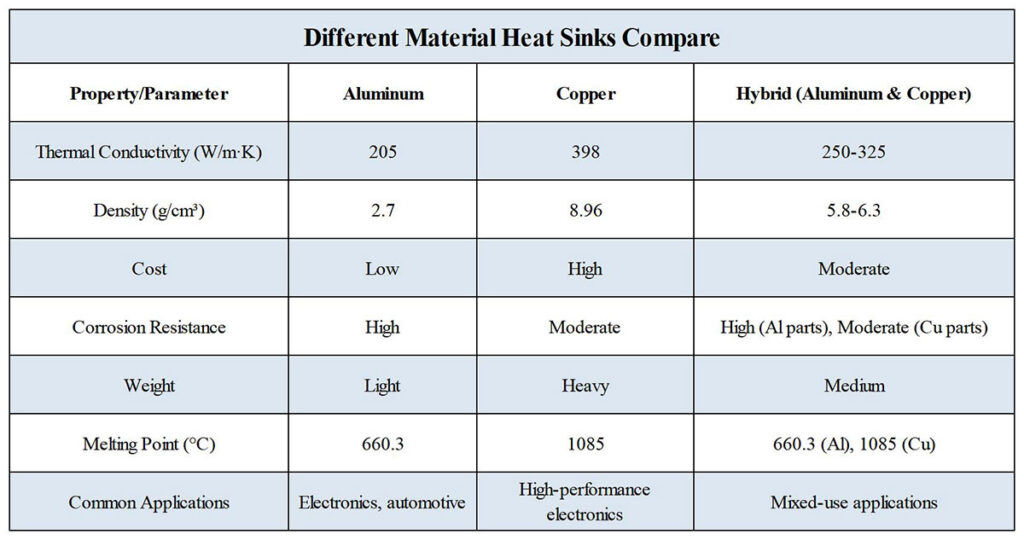

Selecting the proper material impacts the effectiveness and efficiency of a heat sink. Aluminum is frequently used due to its lightweight nature and ability to conduct heat well, making it both affordable and reliable for many LED applications. Copper, while more costly, offers superior thermal performance, often used where maximum heat dissipation is needed. However, the choice of material can be influenced by the LED's environment and specific requirements. For instance, in a harsh or corrosive atmosphere, additional coatings or treatments may be necessary to enhance durability. Understanding these properties can help make informed decisions when designing or selecting a heat sink.

How to make a LED heatsink?

Here are the common methods for producing heat sinks:

-

- Extrusion

-

- Die casting

-

- Bonded Fin

-

- Skiving

-

- Forging

-

- CNC Machining

-

- 3D Printing

Creating an efficient LED heatsink involves understanding the fundamental principles of heat transfer and material properties.

To make a LED heatsink, select an appropriate material like aluminum or copper, shape it to maximize surface area, and consider adding fins for improved heat dissipation.

Making your own LED heatsink requires careful planning and understanding of thermal dynamics. Start by choosing a material that best suits your LED requirements, considering factors like thermal conductivity and cost. Aluminum is commonly preferred for DIY projects due to its ease of use and good thermal properties. Next, decide on a shape that maximizes surface area, allowing more space for heat to disperse. Fins or ridges can be added to further enhance airflow and cooling ability. Finally, ensure that your design fits the intended LED application, whether for simple home use or more complex commercial installations. Prototyping and testing different designs can lead to optimized performance and satisfy specific needs.

What material is best for a heat sink?

Selecting the best material ensures that your LED lighting operates efficiently and remains durable in various environments.

While aluminum is widely used for its balance between performance and cost, copper offers superior thermal conductivity for high-performance applications.

When determining the best material for a heat sink, it's important to weigh various factors, including thermal performance, cost, weight, and environmental considerations. Aluminum remains a popular choice because it offers a good mix of thermal conductivity and affordability. Its lightweight nature allows for versatile design options. Copper, though heavier and more expensive, provides exceptional thermal performance, often employed in scenarios where optimal heat dissipation is crucial. Exploring composite materials or hybrids can also offer alternative solutions, combining different material benefits. Overall, the best choice will be guided by specific application needs, budgetary constraints, and desired performance outcomes.

Conclusion

Understanding heat sink types and materials enhances LED performance and longevity, offering tailored solutions for varied lighting needs.