It can be tough finding a reliable supplier for sheet metal stamping parts. It's essential to choose wisely to avoid potential pitfalls.

To find a good supplier, consider looking in China due to its reputation for reliability and competitive pricing. A trustworthy supplier will prioritize problem-solving, ensuring quality and fair pricing for mutual success.

Choosing the right supplier is the foundation of a successful partnership. I've worked with many companies and know firsthand how crucial it is.

What Should I Consider When Choosing a Sheet Metal Stamping Parts Supplier?

Choosing the wrong supplier leads to issues with quality and delays. This impacts your production schedule and customer satisfaction.

Consider the supplier’s experience, production capacity, and commitment to quality standards. A good supplier is reliable, offers competitive pricing, and is focused on building a sustainable relationship.

You need to evaluate several factors before selecting your supplier. Here’s a deeper dive:

- Experience: Ensure they have a track record in the industry.

- Production Capacity: They should meet your volume without sacrificing quality.

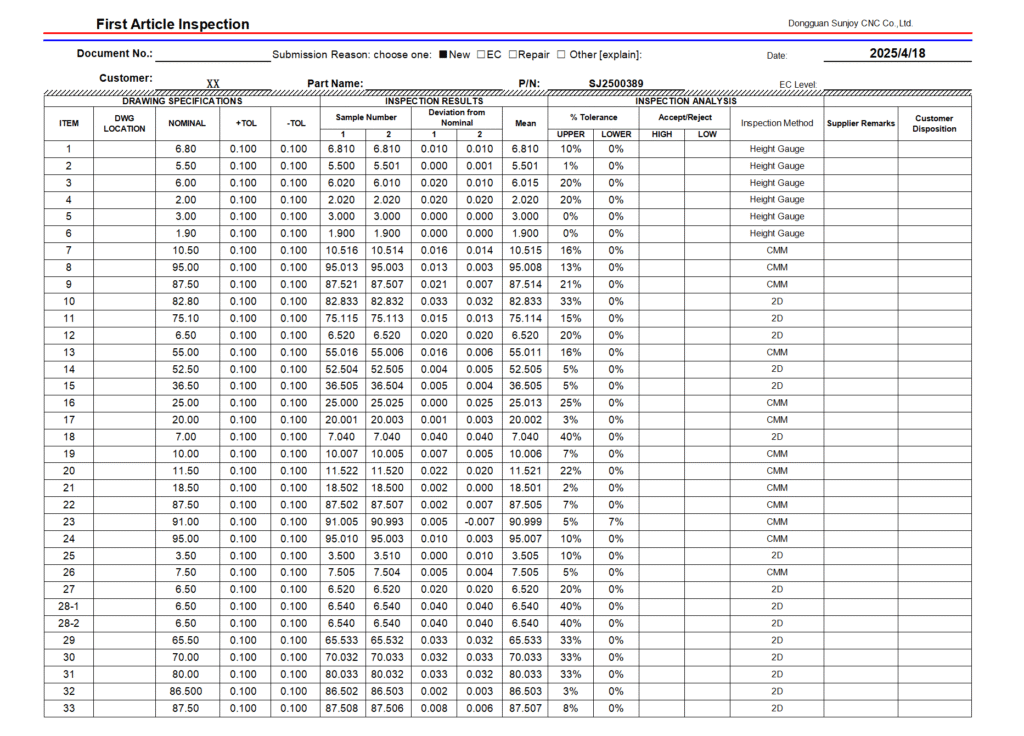

- Quality Control: Look for certifications and their quality assurance process.

Understanding these aspects aligns your expectations and reduces risks down the road.What Kind of Sheet Metal Stamping Parts Supplier is Better?

Choosing from numerous suppliers can be overwhelming; finding the right fit is key.

The better supplier is not just cost-effective but also reliable, with excellent customer service and the ability to adapt to your needs.

A superior supplier understands your industry and adapts quickly to changes, providing custom solutions:

- Adaptability: They should adjust processes for specific needs.

- Problem Solving: Their team should resolve issues promptly.

- Communication: Open lines are crucial for transparency and trust.

These qualities ensure your production runs smoothly and efficiently, maximizing the benefits for your projects.What Can Sunjoy Do for Sheet Metal Stamping Parts?

Understanding what a supplier can offer is vital for decision-making.

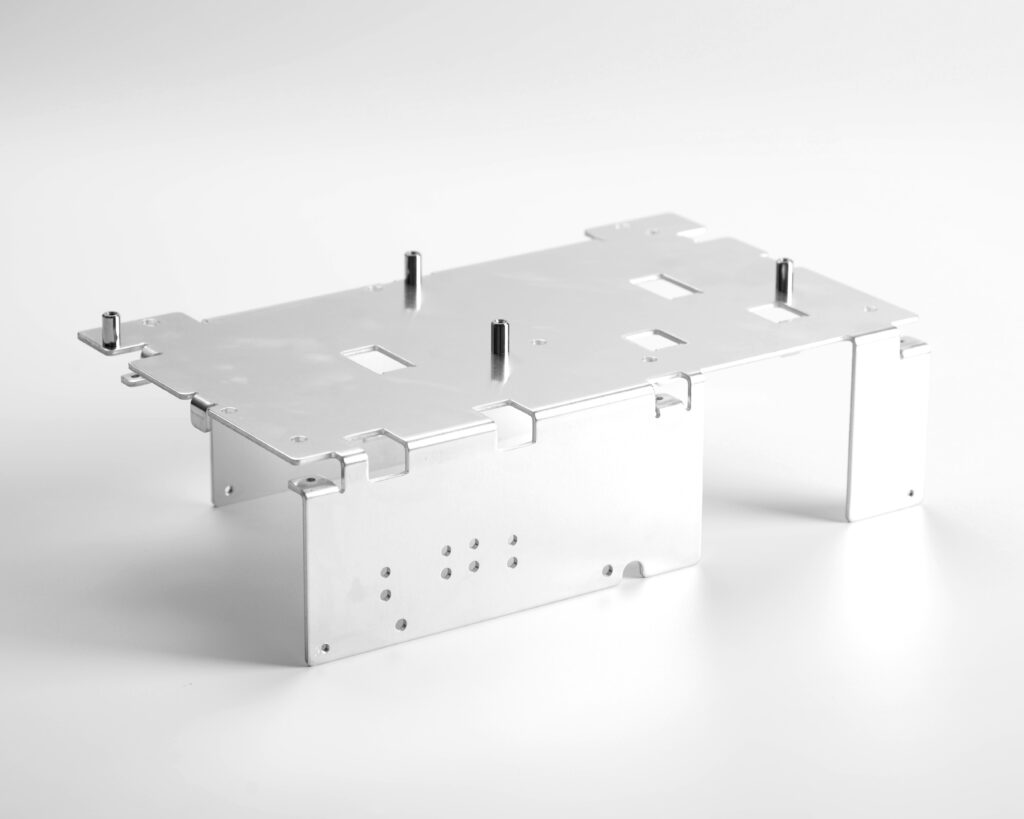

Sunjoy delivers reliable, high-quality sheet metal stamping parts designed to meet industry standards efficiently.

Sunjoy’s approach is client-focused, providing comprehensive solutions:

- Customization: Tailored solutions to meet unique specifications.

- Innovation: Keeping up with technological advances in design and materials.

- Partnership: Building a collaborative relationship to ensure mutual success.

These advantages position Sunjoy as a preferred partner in the field of sheet metal stamping parts.What is Sunjoy's Core Competence?

Understanding core competencies helps determine a supplier's true value.

Sunjoy’s core competencies lie in its technical expertise, innovative solutions, and commitment to quality and customer satisfaction.

Sunjoy’s strength comes from combining experience with innovation:

- Technical Expertise: Skilled engineers like Alan Dong drive quality.

- Innovation: Always improving processes and products.

- Customer Focus: Ensuring solutions meet customer needs effectively.

These competencies ensure that Sunjoy remains a leader in the industry, driven by a commitment to excellence.Conclusion

Choosing the right sheet metal stamping parts supplier involves evaluating experience, adaptability, and trust. Sunjoy stands out with its expertise and client-focused approach.