CCTV cameras are everywhere, but have you wondered how their essential parts come together? Understanding this can help you choose better products or design them yourself.

CCTV camera parts like casings and mounting brackets often use sheet metal stamping for durability and precision. This process is essential for ensuring protection and proper functionality.

Choosing metal stamping components can enhance the camera's lifespan and reliability.

What Are The Components of A CCTV Aamera?

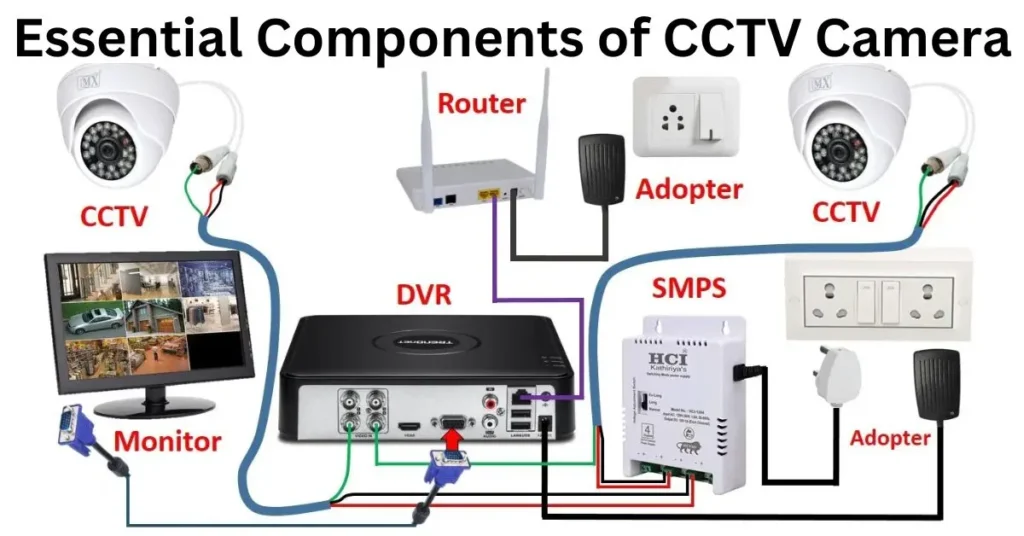

CCTV cameras consist of various parts that work together to provide surveillance. These include the lens, sensor, housing, and DVR/NVR systems.

CCTV cameras have lenses, sensors, housings, and DVR/NVR units. Each part plays a crucial role in capturing, storing, and transmitting video footage. Proper assembly ensures optimal performance for security needs.

To dive deeper, components such as the lens and sensor are the heart of image capturing. The lens focuses light onto the sensor, which records the image. The housing protects these vital parts, often made from stamped sheet metal for durability. The intricate work on DVR/NVR systems allows for video storage and retrieval. DVR/NVR are also made from stamped sheet metal. Understanding the interplay between these components helps ensure seamless operation, meeting both security needs and aesthetic requirements.

What components of CCTV camera can be produced by sheet metal stamping?

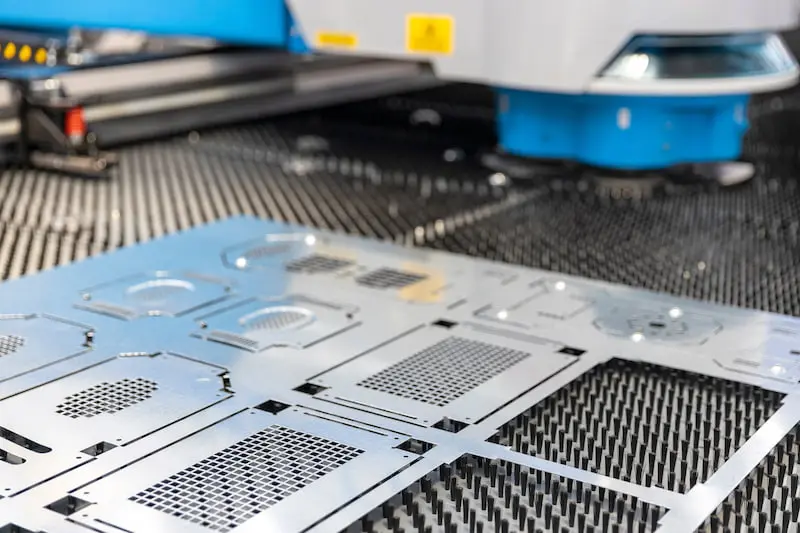

Metal stamping suits components requiring durability and precision, notably mounts, casings, and brackets. It provides stability and reliability essential for outdoor and indoor security applications.

Sheet metal stamping produces mounts, casings, and brackets for CCTV cameras. These components ensure stability, robustness, and reliability, crucial for both indoor and outdoor security solutions.

Exploring further, sheet metal stamping allows for precise shaping and cutting of metal parts. This process is ideal for manufacturing brackets, mounts, and casings, which need to withstand environmental challenges. The stamping process offers versatility, enabling the production of complex shapes and sizes, ensuring seamless integration with other parts. It also allows for various finishing options, from powder coating to galvanizing, enhancing corrosion resistance and aesthetic appeal.

How long will take to produce sheet metal stamping parts?

The production time for sheet metal stamping parts depends on design complexity and material choice. Most of them can be finished about 3-4weeks(the mold design needs about 2-3weeks). Efficient planning and execution can lead to quick turnaround times for seamless production.

Production time hinges on design complexity and materials used for sheet metal stamping. Careful planning allows rapid turnaround, ensuring efficient processing and delivery of quality parts.

Looking deeper, design complexity significantly impacts production timelines. Simple designs may be completed within days, while intricate parts might take longer due to precision requirements. Material choice also plays a role—different metals behave diversely under stamping, affecting processing speed and costs. Properly planned and executed processes can optimize both time and resources, ensuring cost-effective solutions without compromising quality.

Can Sunjoy Assemble CCTV Aamera Components?

Sunjoy leverages its expertise in CNC and die-casting to offer assembly of stamped parts, ensuring integrated solutions for security devices. Our specialized processes enhance product quality and efficiency.

Sunjoy can assemble stamped components for CCTV cameras, using expertise in CNC and die-casting. We provide integrated security solutions, enhancing quality, functionality, and efficiency in assembly.

Taking a closer look at Sunjoy's capabilities, our experience in CNC and die-casting allows for precise and efficient assembly of parts, ensuring optimal functionality. We specialize in the production and integration of sheet metal stamped components, such as brackets, casings, and mounts. Using modern equipment and skilled expertise, we guarantee seamless fits and reliable surveillance solutions, meeting both high aesthetic and performance standards. This holistic approach ensures the delivery of products that stand the test of time.

Conclusion

Understanding CCTV camera components and manufacturing processes helps improve security solutions' design and reliability, ensuring quality and precision in every part.