In the fast-paced world of electronics, precision and appearance are paramount. How can manufacturers meet these demanding standards?

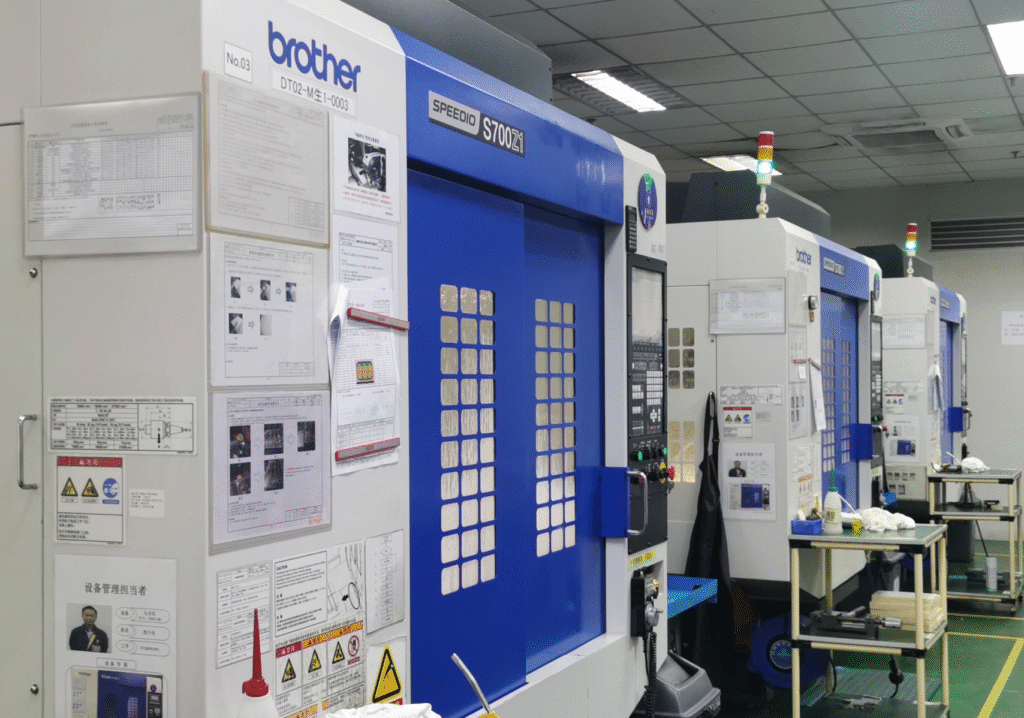

CNC machining is ideal for electronics housings because it ensures precise tolerances and superior finish. This process meets both aesthetic and functional criteria, essential for high-performance applications.

When crafting intricate and appealing electronics housings, CNC machining stands out as a vital tool. It offers precision that can define a product’s reliability and attractiveness—key elements as consumer expectations rise.

What is the main advantage of machining?

Complex manufacturing challenges demand precise solutions. But what sets machining apart in delivering these results?

Machining provides unparalleled accuracy and finish. It’s capable of creating intricate designs while maintaining structural integrity, making it a cornerstone in high-performance manufacturing.

Delving deeper, the main advantage of machining lies in its precision. Whether it’s a simple or complex component, machining ensures micro-level accuracy that manual methods cannot achieve. This precision is crucial in industries where even slight deviations can lead to failures. Another important factor is its ability to maintain consistent quality across large production runs, so all units match the initial design. Meeting strict deadlines is another strength, as machining automates processes and speeds up production without sacrificing quality. These capabilities make machining essential in modern manufacturing.

What Are The Advantages of CNC Machining Over Manual Machining?

High-tech industries seek efficiency. How does CNC machining offer more than manual methods?

CNC machining surpasses manual methods by providing accuracy, speed, and repeatability, eliminating human error, and optimizing production efficiency at scale.

When exploring CNC machining, its advantages over manual processes become apparent.

First, CNC machines operate continuously, holding tight tolerances effortlessly. This enables them to handle complex designs and materials that manual methods struggle with.

Secondly, CNC machines reduce production time, facilitating rapid prototyping and faster time-to-market.

Another plus is that CNC systems store designs digitally, allowing easy updates and adjustments.

So, changes can be made quickly and efficiently without starting from scratch. This ability to easily adapt underscores CNC's advantage in meeting evolving demands.

What is CNC machining Best Known For?

In manufacturing, reliability is key. But what makes CNC machining stand out in this respect?

CNC machining is best known for its precision and ability to execute complex designs consistently. This makes it a trusted solution across various industries.

In further detail, CNC machining is celebrated for translating intricate designs into reality, maintaining high precision throughout production. Its digital accuracy is unmatched, reducing errors significantly compared to manual fabrication. This precision facilitates the production of complex geometries that are otherwise challenging. Additionally, CNC machining supports a wide range of materials, enhancing its versatility. This adaptability makes it ideal for sectors like aerospace or automotive, where rigorous standards are non-negotiable. Emphasizing agility, CNC machining accommodates design variations swiftly, a notable asset in today's fast-evolving markets.

Why Is CNC machining Considered Advantageous For Mass Production?

Meeting consumer demands involves scalability. So, how does CNC machining play a role?

CNC machining is advantageous for mass production due to its speed, efficiency, and ability to deliver consistent quality across large volumes, minimizing waste and reducing costs.

On a deeper level, CNC machining excels in mass production by automating repetitive tasks, which enhances efficiency. It minimizes human involvement, reducing labor costs and potential errors. CNC machines maintain consistency, ensuring each piece is identical to the prototype—crucial for brand reputation. Economically, the CNC's waste reduction capabilities trim material costs significantly, as the process is tightly controlled and optimized. This makes it sustainable and cost-effective. Scalability is another point; CNC systems can quickly ramp up production levels, meeting market demands without downtime.

Conclusion

CNC machining is indispensable for high-performance electronics housings, offering unmatched precision, reliability, and scalability across diverse manufacturing needs.