Poor quality outdoor lighting can lead to safety hazards and frequent replacements. Many lighting manufacturers struggle with finding durable, weather-resistant components that maintain aesthetics.

CNC turning is ideal for outdoor lighting components because it offers precision manufacturing of weatherproof parts through high-quality materials and surface treatments. The process enables creation of complex shapes while maintaining structural integrity needed for outdoor conditions.

As someone who has worked extensively with manufacturing outdoor lighting components, I've seen firsthand how CNC turning can transform the quality and longevity of outdoor lighting products. Let me share what I've learned about the advantages and considerations.

Can CNC Turning Parts Be Used in Outdoor Lighting?

Many lighting manufacturers worry about component durability in harsh weather conditions. Without proper materials and manufacturing, outdoor lights can quickly deteriorate.

CNC turning parts are excellent for outdoor lighting applications, as they can be manufactured from weather-resistant materials like aluminum and stainless steel, with precise specifications for water-resistance and durability.

The versatility of CNC turning makes it particularly valuable for outdoor lighting components. Here's a detailed breakdown of where CNC turned parts are commonly used:

Key Applications in Outdoor Lighting

| Component | Function | Material Choice |

|---|---|---|

| Housing | Protects internal components | Aluminum 6061 |

| Heat Sinks | Temperature management | Aluminum 7075 |

| Mounting Brackets | Structural support | Stainless Steel 316 |

| Lens Holders | Optical element support | Brass |

The precision of CNC turning ensures these components fit together perfectly, creating sealed units that protect against moisture and dust. From my experience, properly manufactured CNC parts can maintain their integrity for years, even in coastal environments with high salt exposure.

What Are the Advantages and Disadvantages of CNC Turned Parts for Outdoor Lighting?

Weather damage and corrosion often destroy outdoor lighting components. Manufacturers need solutions that balance durability with cost-effectiveness.

CNC turned parts offer advantages like precise dimensions, excellent surface finish, and material flexibility, but can have higher unit costs for small quantities and longer production times compared to casting or molding. Our CNC turning production time is 2-3weeks. Casting and molding need 3-4weeks

When evaluating CNC turning for outdoor lighting components, it's crucial to consider both benefits and limitations:

Advantages:

- High precision tolerances (±0.005mm)

- Excellent surface finish

- Material flexibility

- Quick prototype development

- No tooling costs

- Complex geometries possible

Disadvantages:

- Higher unit costs for large volumes

- Limited batch sizes

- Longer production time per piece

- Material waste

- Size limitations

The key is finding the right balance for your specific application. I've found that combining CNC turning with appropriate surface treatments like hard anodizing can create extremely durable components that justify the initial investment.

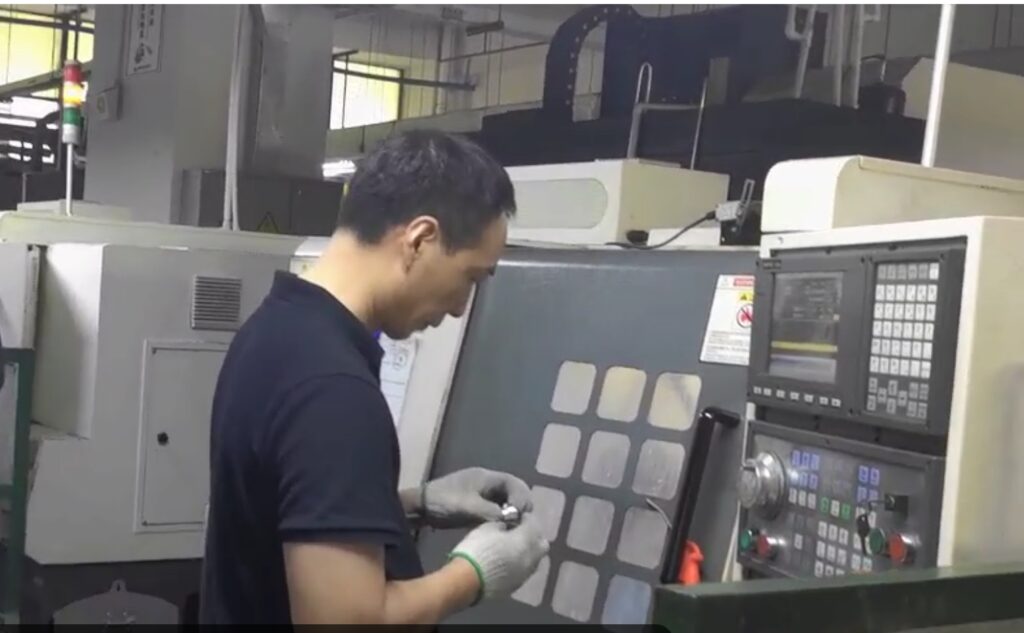

How to Manufacture CNC Turning Parts?

Getting consistent quality in outdoor lighting components can be challenging. Poor manufacturing processes lead to rejected parts and increased costs.

Manufacturing CNC turned parts requires careful material selection, proper programming, and appropriate surface treatment. The process typically involves CAD design, CNC programming, machining, and finishing operations.

The manufacturing process requires attention to detail at every stage:

Manufacturing Steps

- Design Phase

1 CAD modeling

2 Material selection

3 Tolerance specification - Programming

1 Tool path generation

2 Speed and feed calculation

3 Simulation testing - Production

1 Material preparation

2 Machine setup

3 Quality control checks - Post-Processing

1 Surface treatment

2 Assembly verification

3 Final inspection

Based on my experience, successful manufacturing requires close collaboration between designers and machinists to optimize designs for production efficiency while maintaining quality standards.

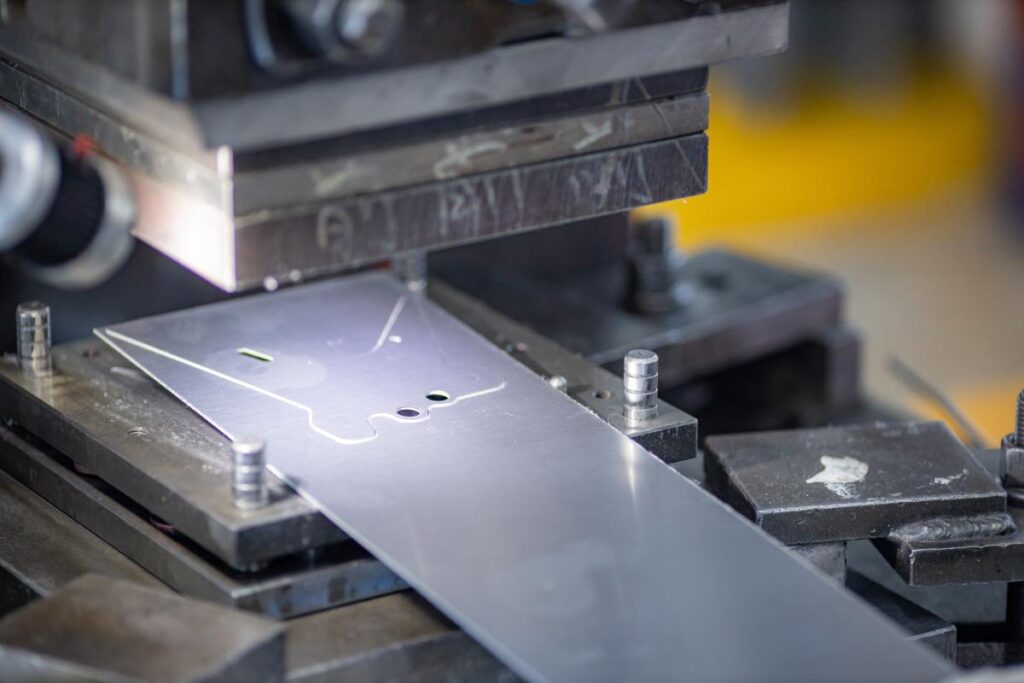

What Can Replace CNC Turned Parts for Outdoor Lighting?

Rising production costs make manufacturers seek alternatives to CNC turning. However, finding options that maintain quality while reducing costs isn't simple.

Alternative manufacturing methods include die casting, injection molding, and metal stamping. Each offers different benefits but may compromise on precision, durability, or initial investment costs.

Let's examine the main alternatives and their suitability:

Alternative Manufacturing Methods

| Process | Advantages | Limitations |

|---|---|---|

| Die Casting | High volume, low unit cost | High tooling cost |

| Injection Molding | Fast production, complex shapes | Limited materials |

| Metal Stamping | Quick, economical | Simple shapes only |

| 3D Printing | No tooling, flexible | Slower production |

While these alternatives can be viable in certain situations, they often can't match the precision and material properties achieved through CNC turning. The choice ultimately depends on production volume, budget, and quality requirements.

Conclusion

CNC turning remains a superior choice for outdoor lighting components due to its precision, material flexibility, and ability to create weather-resistant parts through appropriate surface treatments.