Projectors are more than just bright lights and lenses. They rely on precision-engineered components. Let's explore why metal parts manufactured through CNC processes are crucial for projectors.

To deliver high-quality visuals, projectors require precise components such as heat sinks, chassis, and lens mounts. CNC machining ensures these parts maintain the necessary tolerances for optimal performance.

Metal parts in projectors provide the structural integrity and heat management needed for reliable operation and image quality. Without them, performance would diminish rapidly.

What Are The Parts Of A Projector?

Understanding a projector’s internal anatomy can seem complex. From the outside, projectors project images, but inside, many components work together seamlessly.

A projector includes lenses, light sources, mirrors, color wheels, and electronic circuits. CNC metal parts such as heat sinks and casings are crucial in supporting these components for efficient functioning.

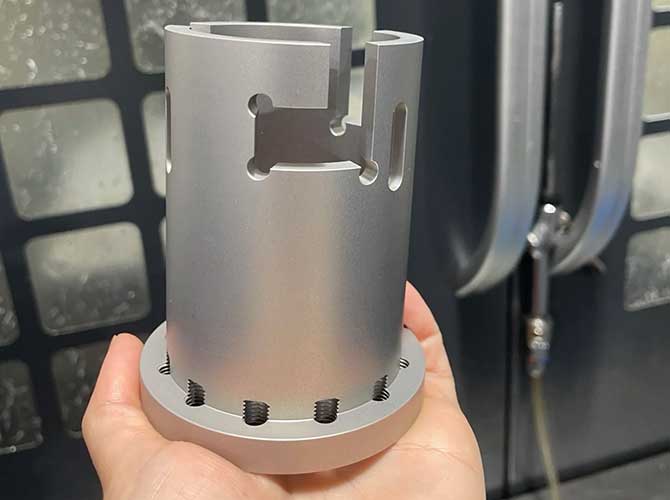

CNC metal parts form the backbone of various projector elements. Lens mounts maintain optical alignment. Heat sinks dissipate excess heat. The metal casing secures and protects sensitive components from external damage, ensuring longevity of the device.

| Projector Part | CNC Metal Component | Function |

|---|---|---|

| Lens Mount | CNC Bracket | Keeps lenses stable and precise |

| Heat Sink | CNC Cut Metal | Manages heat dissipation |

| Casings/Chassis | CNC Metal Frame | Provides structural integrity and safety |

What Is Required For A Projector?

Creating an effective projector involves multiple critical factors. Developing the right design requires attention to detail and specific materials.

A projector needs a high-quality light source, precise optics, advanced cooling systems, and durable housing. CNC machining offers the accuracy required in crafting these metal components to ensure these systems work efficiently.

When designing a projector, selecting CNC machined metal parts ensures each element is manufactured to exact specifications. This includes chassis strength and thermal management systems, which are necessary for performance stability.

How To Control The Quality of Projector CNC Components?

Ensuring high-quality CNC components involves a meticulous approach. Look beyond design to finish and install the parts impeccably.

Quality control in CNC components involves precision measurements, testing, and inspections throughout the production process. Adherence to strict specifications makes sure all parts meet projector requirements.

Effective quality control involves using advanced software for design, automated inspections for precision verification, regular equipment calibration, and skilled technicians who understand the importance of perfection in every piece. Maintaining stringent standards ensures components perform to expectations without fail.

What Are The Challenges to Build Projector CNC Metal Parts?

Creating precision CNC components for projectors isn't without its hurdles. From design complexities to meeting strict tolerances, challenges abound.

Challenges include maintaining accuracy in high-volume production and addressing heat management concerns. Additionally, CNC machining for projectors requires precision handling of delicate materials.

Building CNC metal parts for projectors involves navigating the balance between cost efficiency and quality, refining manufacturing techniques, and developing effective solutions for heat dissipation without compromising structural integrity. Collaboration between designers and engineers is essential to meet these challenges and deliver superior parts.

Conclusion

Precision CNC metal parts are essential in projectors for structural support, heat management, and optical stability. They play a vital role in ensuring devices operate efficiently and effectively.