Is your access control system meeting your needs for precision and durability? Discover why CNC machining might be the solution to elevate your system's performance.

CNC machining offers precision, consistency, and quality for producing components in access control systems. Its high accuracy, ability to work with various materials, and efficient production processes make it ideal for intricate parts required in these systems.

CNC machining enhances both the security features of access control systems and manufacturing efficiency. Let's explore the details.

What Materials Are Ideal for CNC Machining of Access Control Systems and Why?

Choosing the right material is key to achieving durability and functionality in access control systems. But how do you decide which material fits best?

For CNC machining of access control systems, materials like aluminum, stainless steel, and plastics are commonly used. Aluminum is lightweight and strong, stainless steel offers corrosion resistance, and plastics provide cost-effective and versatile options for various components.

Each material offers unique benefits suited to different parts of the system:

-

Aluminum: Known for its strength-to-weight ratio, aluminum is perfect for parts requiring strength without added weight. It's also corrosion-resistant, which helps in maintaining part integrity over time.

-

Stainless Steel: Offers superior resistance to wear and corrosion, making it suitable for components exposed to harsher environments or requiring more durability.

-

Plastics: Used for parts that don't require excessive strength. These are lightweight and often used for cost-effective solutions in non-structural applications.

What Surface Finishes Are Good For Access Control System Machined Components?

How do you ensure a professional and durable finish for your CNC machined components?

Surface finishes such as anodizing, powder coating, and electroplating are ideal for access control components. Anodizing adds a protective oxide layer to aluminum parts, powder coating provides a robust finish, and electroplating enhances aesthetics and corrosion resistance.

To achieve a lasting and appealing finish, consider these options:

- Anodizing: This adds a layer of protection to aluminum parts. It's valuable for improving resistance to wear and corrosion, which is critical for external components.

- Powder Coating: Offers a durable and visually appealing finish. It's ideal for maintaining the aesthetic quality of visible components while providing additional protection.

- Electroplating: Enhances both aesthetics and resistance to corrosion. It involves coating components with a thin layer of metal, extending the life of parts particularly exposed to moisture.

How To Control the Quality for Access Control System CNC Machined Components?

What steps can ensure the highest quality standards for your CNC machined components?

Implementing stringent quality checks at each stage of the manufacturing process is crucial. Regular inspections, precise measurements, and rigorous testing contribute to maintaining ideal quality levels for access control components.

Quality control in CNC machining involves:

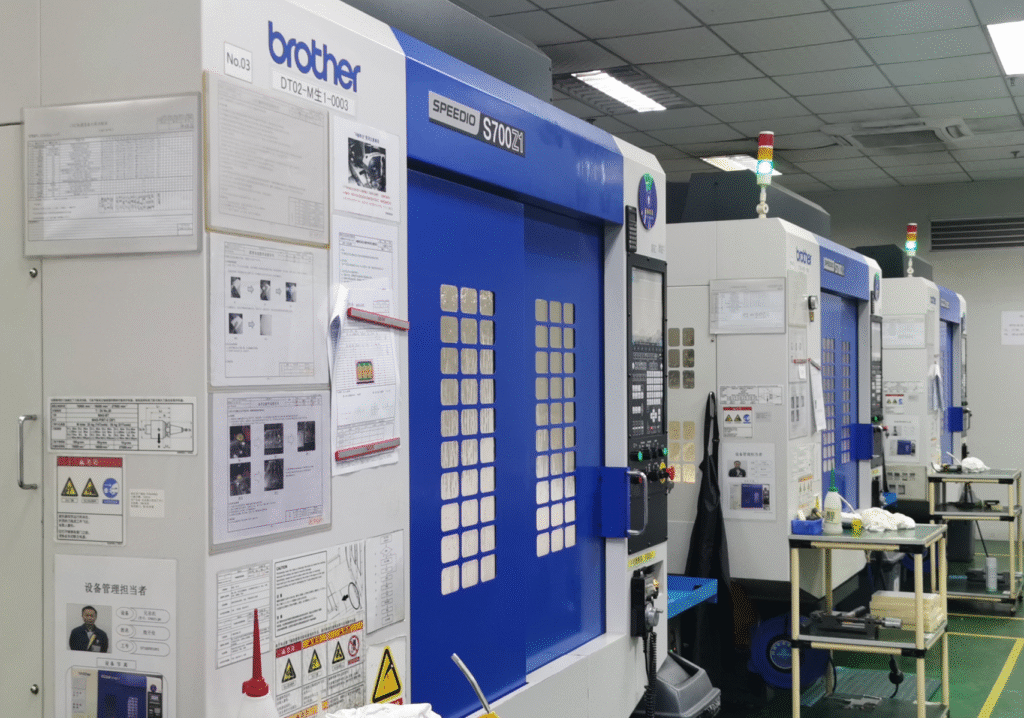

- In-Process Inspection: Regular(every 2 hours) checks during production help identify and correct issues immediately, reducing waste and improving final product quality.

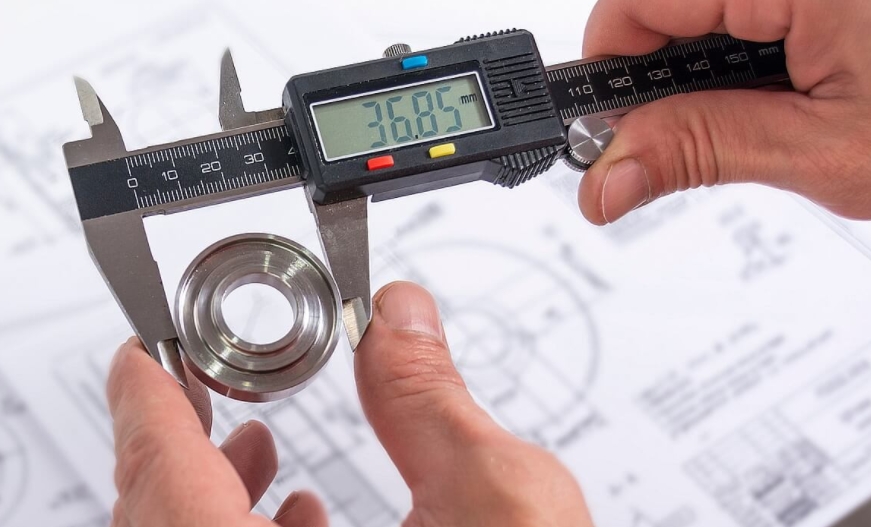

- Precision Measurements: Using advanced measurement tools ensures each part meets the specified dimensions and tolerance levels.

- Testing and Validation: Components undergo functional testing to verify performance under different scenarios, ensuring reliability and effectiveness when deployed in the field.

What Tolerance Can Sunjoy Achieve with CNC Machining?

Wondering about the precision limits of our CNC machining?

Sunjoy offers a precision level of up to ±0.01 mm with CNC machining. This high tolerance ensures that components fit perfectly and perform reliably, holding true to design specifications and functional requirements.

With tolerances up to ±0.01 mm, Sunjoy excels in:

-

Precision Manufacturing: Allows for complex designs to be executed with high accuracy, ensuring consistent and reliable component performance.

-

Consistent Quality: Every part meets stringent standards, providing clients with products that enhance system reliability and functionality.

-

Efficiency and Scalability: High precision with CNC machining means fewer errors and faster production rates, enabling cost-effective scaling as demand grows.

Conclusion

Precision, quality, and durability make CNC machining an excellent choice for access control systems. Sunjoy’s expertise ensures these standards are met efficiently.